2200Q2JE-HO-KHM-N_2015.02.

Chapter 5 Maintenance and Inspection

Ammonia Semi-hermetic Motor with K-series Compressor 5.1 Precautions for Maintenance

5-20

5.4.6 Motor Bearing Retainer

a) Apply oil on the planetary ring of the motor bearing

[613] and the lip part (in contact with the shaft) of the

motor oil seal [617].

b) Screw two stud bolts (safety bolts) into appropriate top

bolt holes.

c) Apply oil on the gasket [615] and attach it to the bearing

retainer [614] so that the bolt holes allow the stud bolt

to enter.

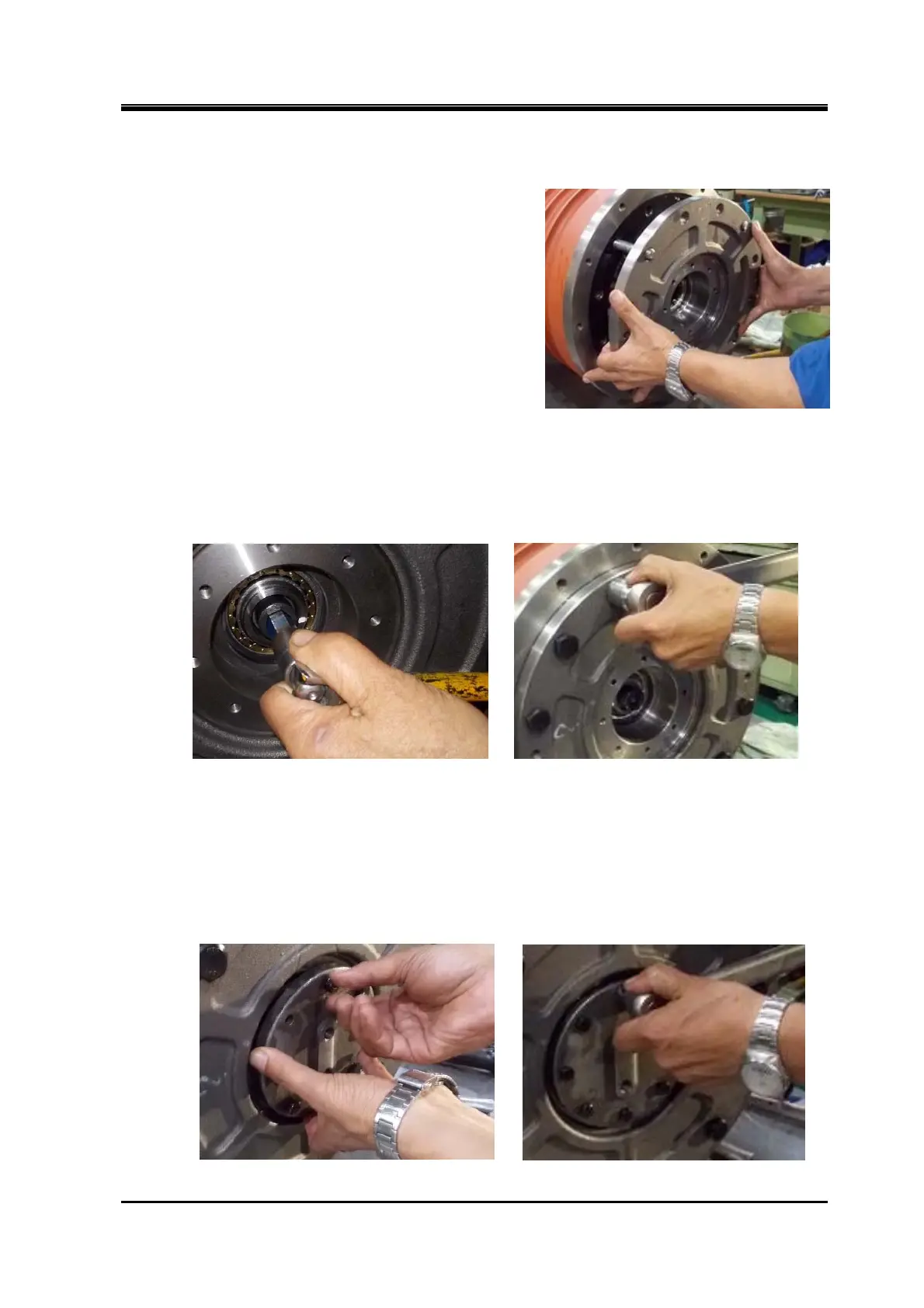

d) While holding the bearing retainer with both hands,

mount it in the motor casing (picture to the right).

Push the motor rotor shaft [607] into the bearing that

has already been mounted in the bearing retainer.

As the shaft is pushed in, the bottom end of the spigot section hits the flange hole in the motor

casing. In that case, further push in the spigot section while bring it up, it can be mounted onto the

flange surface.

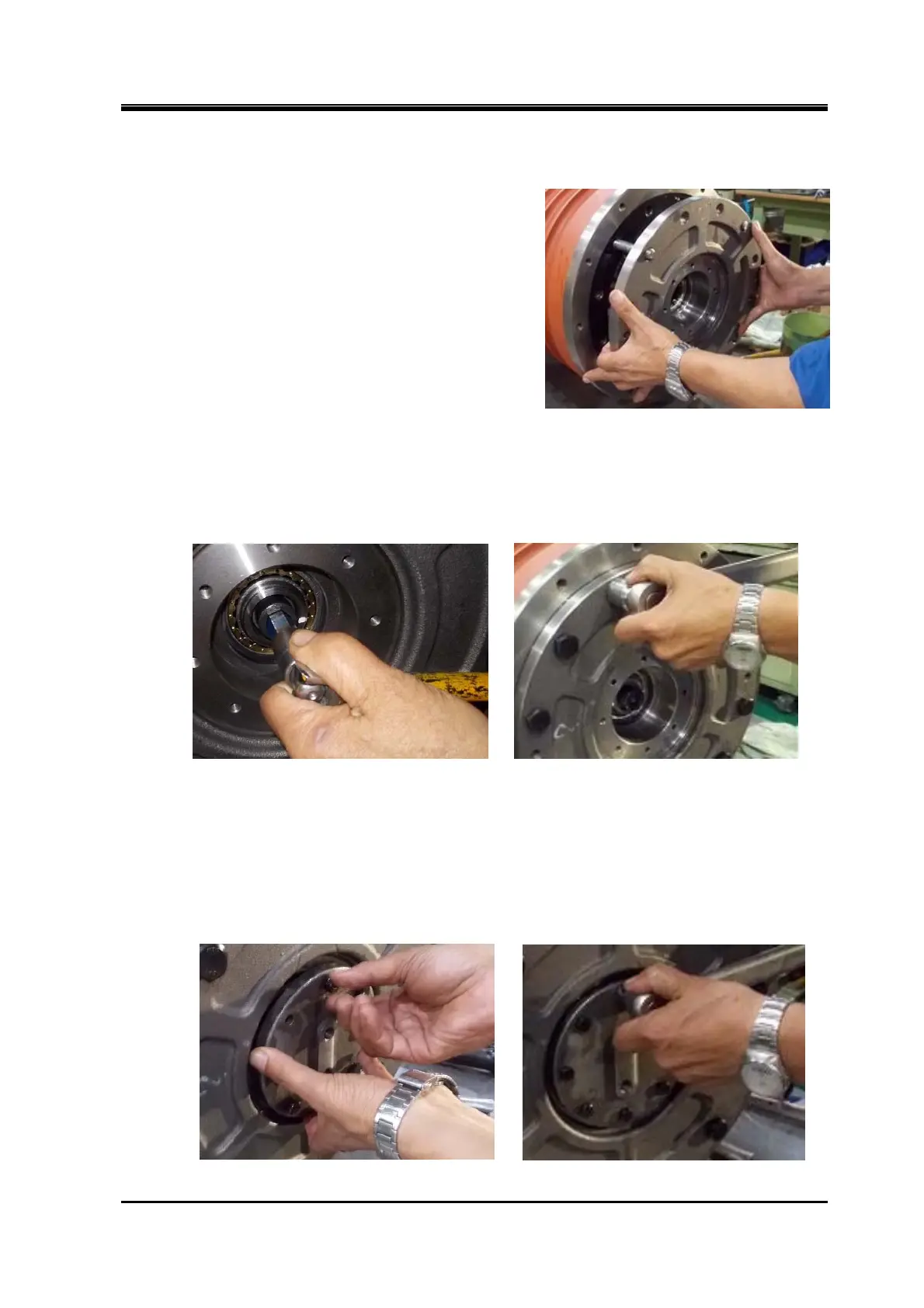

e) After slightly tightening the motor oil seal retainer fastening bolts [619] and fit the hexagonal bar

wrench to the motor rotor mounting bolt [609], ensure that the shaft can be turned by hand

(following picture to the left), tighten them with the specified torque (following picture to the right).

5.4.7 Motor End Cover

a) Apply oil on the gasket [621].

Attach the gasket to the flange of motor end cover [620] while allowing it to the bolt holes.

b) While fitting the motor end cover to the motor bearing retainer (following picture to the left), screw

in the eight bolts [622], and then tighten them with the specified torque (following picture to the

right).

Loading...

Loading...