Chapter 5 Maintenance and Inspection

UD-series Screw Compressor 5.4 Disassembly and Inspection

5-29

Inspection

a) After thoroughly cleaning the thrust bearings, remove the cleaning solution with compressed

air.

First, make sure that the surface of the ball is evenly shiny and that there are no

scratches or flaking.

Next, inspect the corners of the retainer (thrust bearing retainer) ball hole for blisters and

wear.

In either case, replace the bearing set.

b) Hold one of the bearings in your hand and rotate the outer ring by hand with the inner ring

facing downward.

(Make sure the inside of the combination is facing down). If the rotation is

not smooth and it is uneven or hooked, it is caused by dust or scratchesIn that case, check

again and wash or replace the bearing set if necessary.

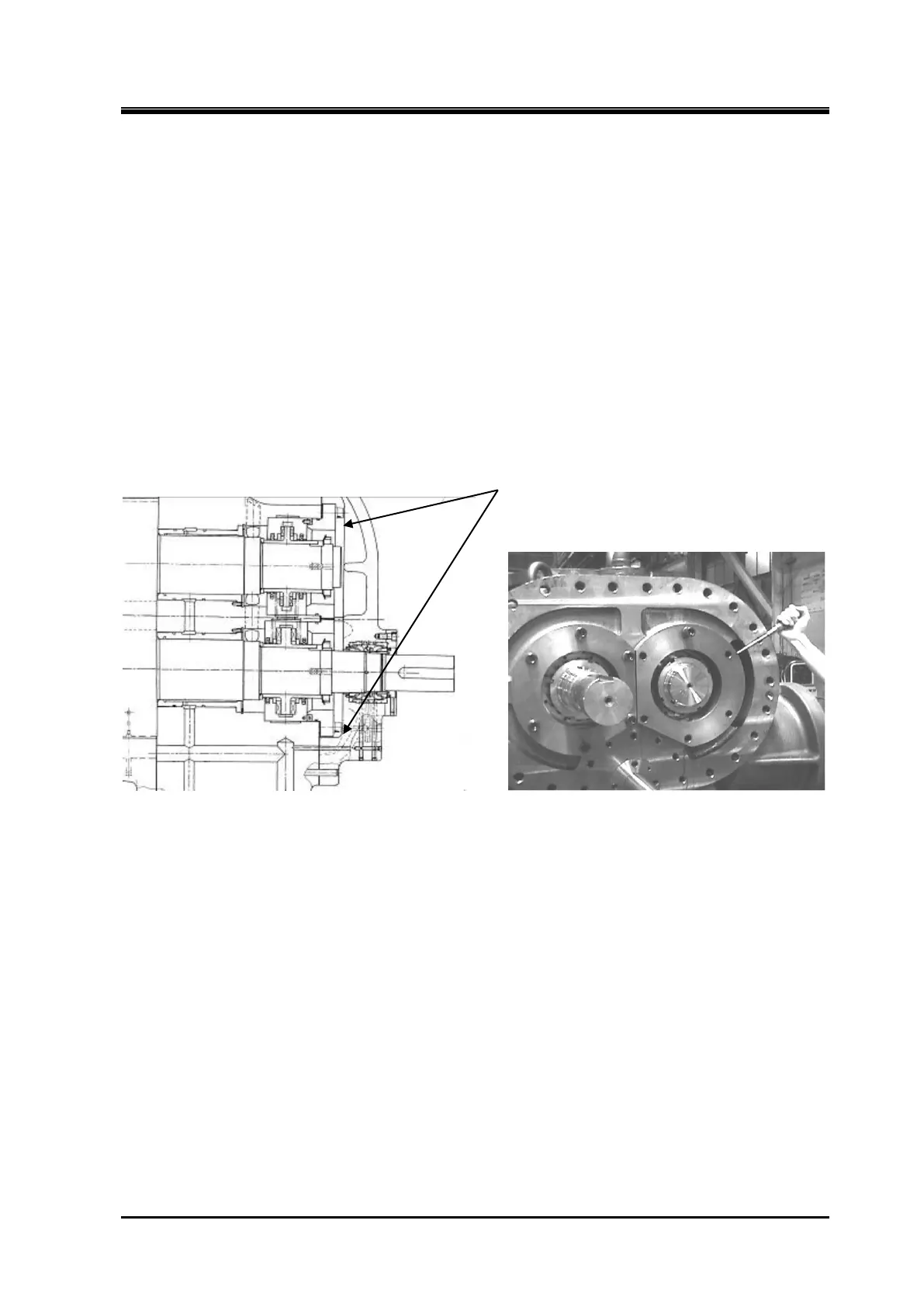

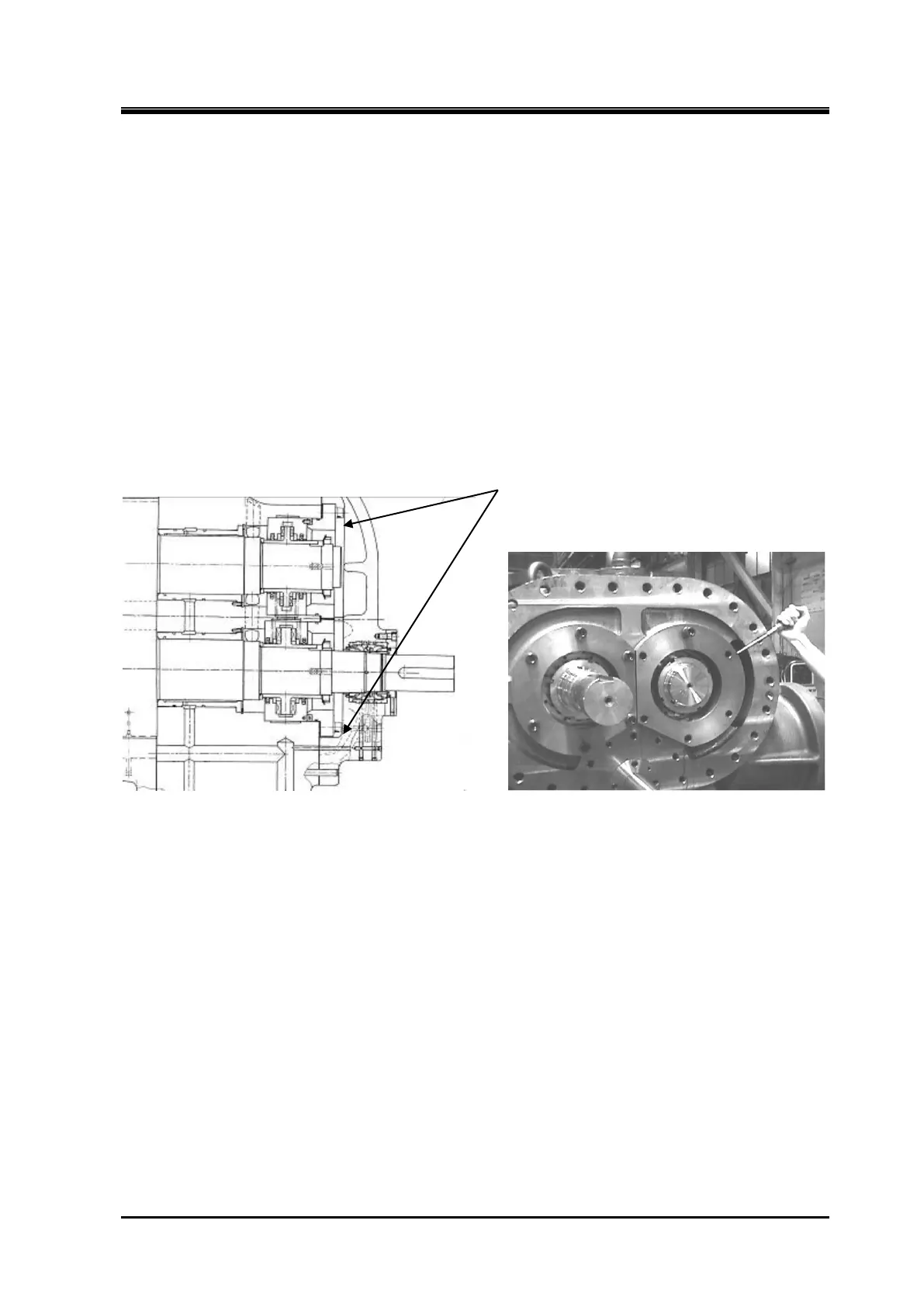

Tilting pad thrust bearing (TPTB, 400*UD)

Disassembly

Thrust Bearing Gland

Figure 5-14 TPTB Thrust Bearing Gland (1)

a)

Loosen the hexagon socket head cap screw and insert the lifting eye bolt into the bolt hole on

the upper part of the thrust bearing gland.

b)

Lift up the thrust bearing gland, remove the bolt, and insert the safety bolt on top of the thrust

bearing gland.

Pull out the thrust bearing gland using a flathead screwdriver. Remove the

thrust bearing gland and pull out the other thrust bearing gland in the same way.

Loading...

Loading...