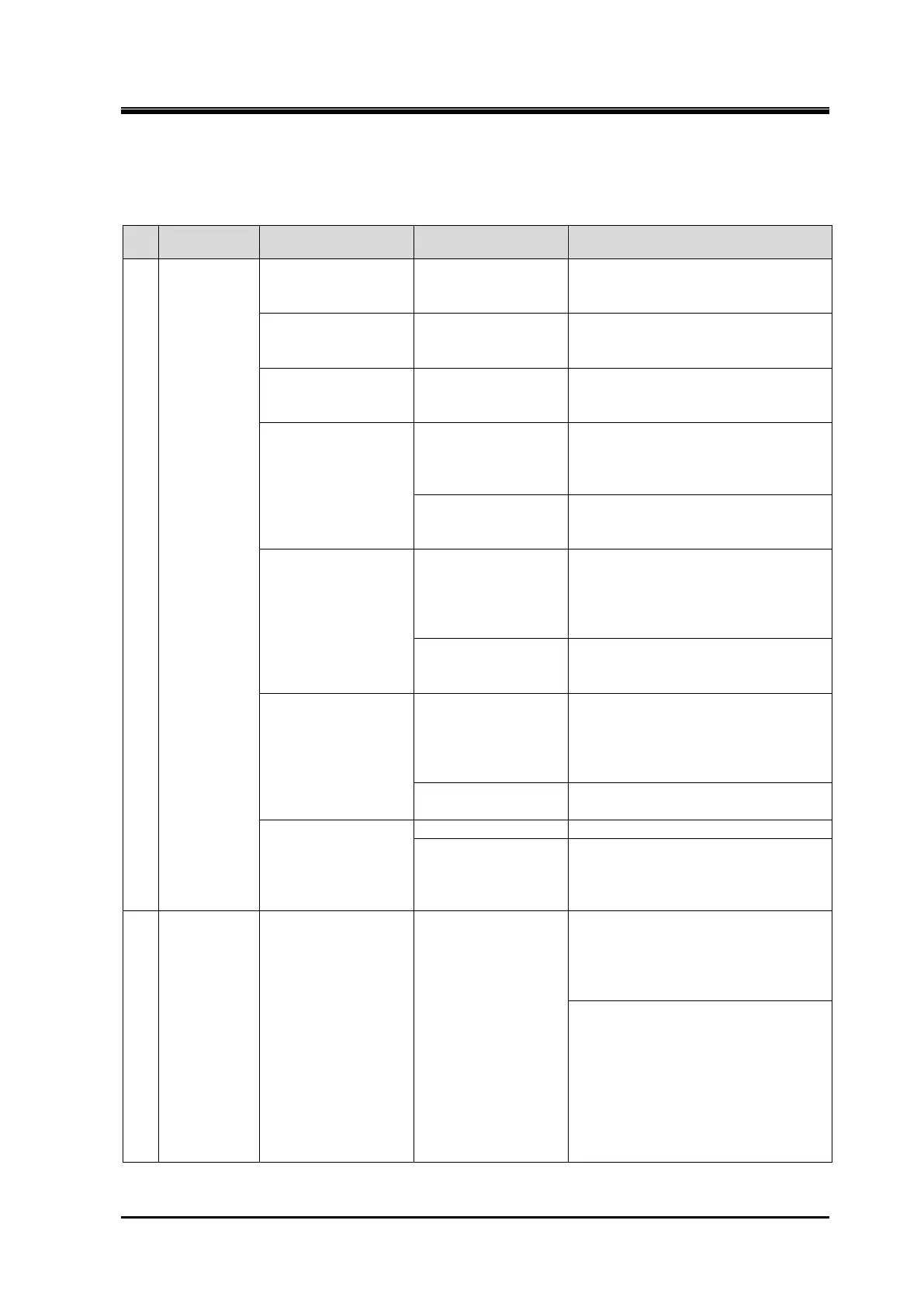

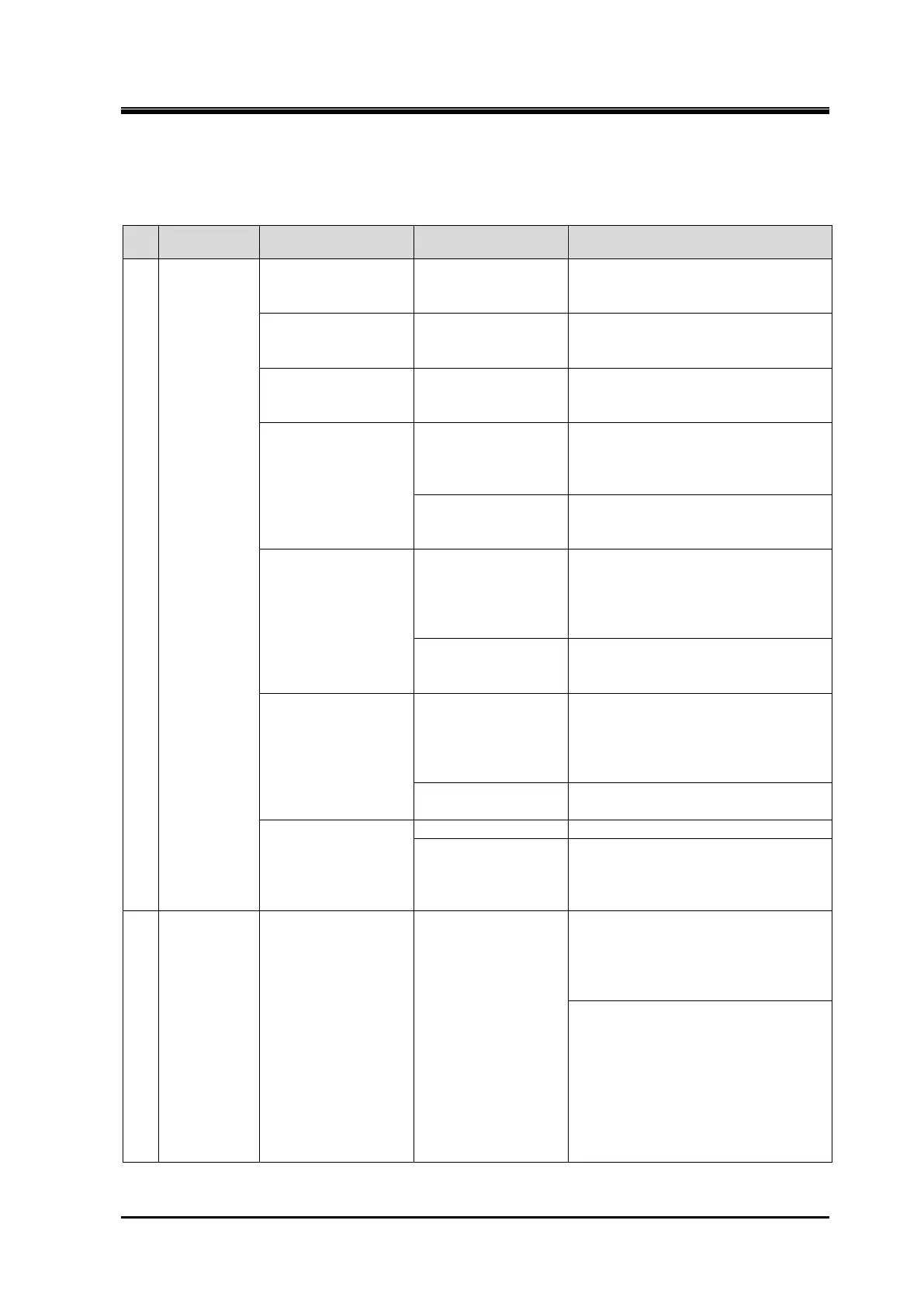

Chapter 6 Troubleshooting

UD-series Screw Compressors

6-1

Chapter 6 Troubleshooting

Table 6-1 Troubleshooting

Trouble Direct causes Factors Actions

does not

start up

turned on after

Prevent oversight by checking a

check sheet after inspection.

malfunction

to overload

Refer to the motor instruction

manual as well for other causes and

0% undetected by

micro-switch

hydraulic circuit

defect

flow control valve

(decreased too

pipes and solenoid

Remove factors. Check oil

contamination level and replace oil

hydraulic pressure

draulic pressure

protection device,

pressure sensor,

Identify malfunctioning devices,

examine their causes, and take

measures.

Then, replace malfunctioning

connecting pipes

Remove clogging. Check oil

contamination level and replace oil

cooling water

circulation

devices such as

cooling water

pumps and related

Identify malfunctioning devices,

examine their causes, and take

measures.

Then, replace malfunctioning

Clogging in circula-

tion routes

nets, relays, etc., in

compressor start

circuit

Replace with new devices.

environment

Replace ventilation fans, etc, if

malfunctioning.

Improve temperature, humidity, and

ventilation for installation site.

stops imme-

diately after

startup.

protection circuit

(switch) activated

ant circulation

volume

Insufficient refrig-

erant amount

Insufficient refrig-

erant supply

Heat exchange

failure at heat

exchanger

For insufficient refrigerant amount,

check the system and stop leak,

and then recharge refrigerant.

* Be cautious about moisture

contamination in the system.

For insufficient supply, inspect

expansion valves and liquid supply

strainers, and then take necessary

measures.

Also, inspect devices and

parameters (setting values) for

expansion value aperture (opening)

adjustment device, and then take

Loading...

Loading...