NI 9220 Calibration Procedure | © National Instruments Corporation | 3

Test Equipment

Table 1 lists the equipment recommended for the performance verification and adjustment

procedures. If the recommended equipment is not available, select a substitute using the

requirements listed in Table 1.

Test Conditions

The following setup and environmental conditions are required to ensure the NI 9220 meets

published specifications.

• Keep connections to the NI 9220 as short as possible. Long cables and wires act as

antennae, picking up extra noise that can affect measurements.

• Verify that all connections to the NI 9220 are secure.

• Use shielded copper wire for all cable connections to the NI 9220. Use twisted-pairs wire

to eliminate noise and thermal offsets.

• Maintain an ambient temperature of 23 °C ±5 °C.

• Keep relative humidity below 80%.

• Allow a warm-up time of at least 10 minutes to ensure that the NI 9220 measurement

circuitry is at a stable operating temperature.

Initial Setup

Complete the following steps to set up the NI 9220.

1. Install NI-DAQmx.

2. Make sure the NI cDAQ-9178 power source is not connected.

3. Install the module in slot 8 of the NI cDAQ-9178 chassis. Leave slots 1 through 7 of the

NI cDAQ-9178 chassis empty.

4. Connect the NI cDAQ-9178 chassis to your host computer.

5. Connect the power source to the NI cDAQ-9178 chassis.

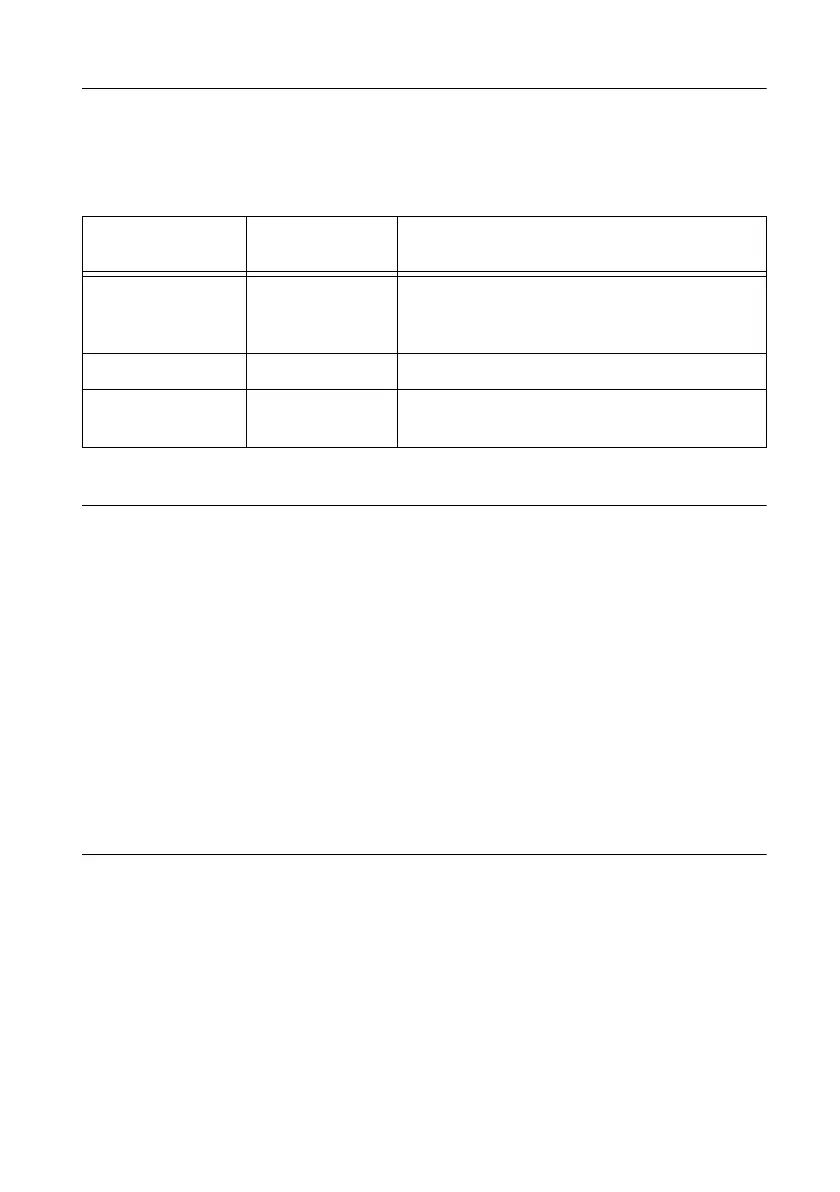

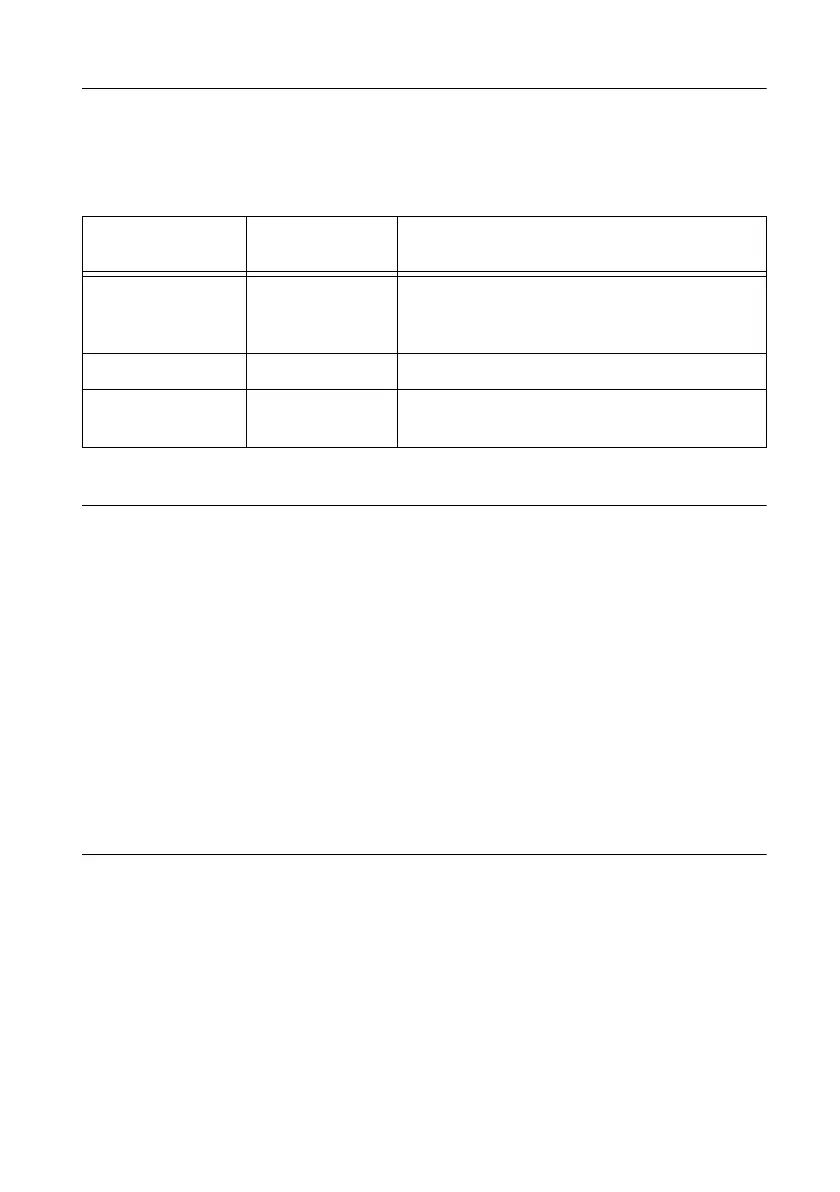

Table 1. Recommended Equipment

Equipment

Recommended

Model

Requirements

Calibrator Fluke 5700A Use a high-precision voltage source with an

accuracy of ≤15 ppm and an output impedance

of ≤50 Ω.

Chassis NI cDAQ-9178 —

DSUB Connection

Accessory

NI 9923 —

Loading...

Loading...