6 | ni.com | NI VirtualBench Calibration Procedure

These steps are described in more detail in the following sections.

Note If you are calibrating both the DMM and the DC power supply, the DMM

must be calibrated first.

DMM Test Equipment

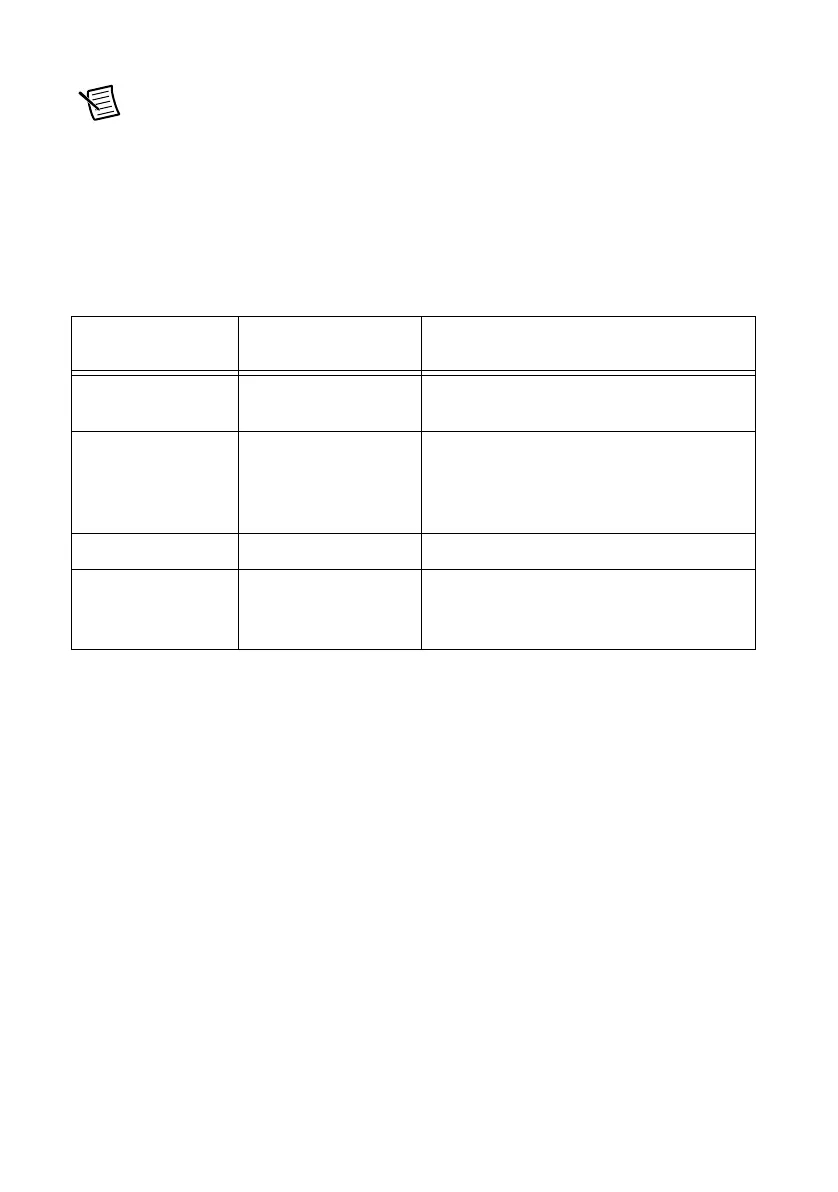

Table 3 lists the equipment recommended for the DMM performance verification and

adjustment procedures. If the recommended equipment is not available, select a substitute using

the requirements listed in the table.

DMM Test Conditions

Follow these guidelines to optimize the equipment and the environment during calibration:

• Keep connections to the device as short as possible. Long cables and wires act as antennae,

picking up noise that can affect measurements.

• Use a USB connection between the PC and VirtualBench.

• Verify that all connections to the device, including front panel connections, are secure.

• Keep relative humidity between 10% and 80% noncondensing.

• Allow a warm up time of at least 30 minutes to ensure that the VirtualBench is at a stable

operating temperature.

• Plug the VirtualBench, PC, and the test equipment into the same power strip to avoid

ground loops.

• Verification limits are defined assuming the same test equipment is used during verification

and adjustment.

• Maintain an ambient temperature of 23 ±1 °C. The device temperature will be greater than

the ambient temperature.

Table 3. Recommended Equipment

Equipment

Recommended

Model

Minimum Requirements

Multifunction

calibrator

Fluke 5700A/

5720A/5730A

Must be calibrated within the last year.

Low thermal

electromotive

force (EMF)

copper cable

Fluke 5440A-7002 Low thermal electromotive force (EMF)

copper cable with 4 mm banana

connectors.

Amplifier Fluke 5725A Must be calibrated within the last year.

Shielded interface

cable for the

amplifier

Fluke 842901 —

Loading...

Loading...