Note

●

When PCB DIP switch 2 #8 is set to On, ensure that

CPVC, polypropylene, or stainless steel is used for

exhaust venting.

●

This unit may be installed at elevations up to 10,100

ft (3,078 m) for use with natural gas and propane. To

use the unit at a specific altitude, the DIP switches

should be set as described above.

●

High Altitude: Above 2,000 ft (610 m), the unit will

de-rate by 3% for each 1,000 ft (305 m) of altitude

gain.

●

For NG, if you install the unit at above 5,400 ft (1,646

m), it is required to change the Gas Orifice for high

altitude. Be careful not to confuse it with the LP Gas

Orifice. Refer to “4.4 Gas & High Altitude Conversion”

on page 25 for details.

●

Common vent installations for use with natural gas

and propane are only approved for up to 4,500 ft.

CAUTION

Ensure that the High Altitude setting reflects the actual

location of the boiler. If not, it may cause personal injury or

malfunction of the boiler.

4.3 Measuring the Inlet Gas Pressure

WARNING

The boiler cannot function properly without sufficient inlet

gas pressure. Measuring the inlet gas pressure should be

performed by a licensed professional only.

●

The inlet gas pressure must be maintained between 3.5 in and

10.5 in WC for natural gas and between 8.0 in and 13.5 in WC for

liquefied propane.

●

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1

/

2

psi (3.5 kPa).

●

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than

1

/

2

psi (3.5 kPa).

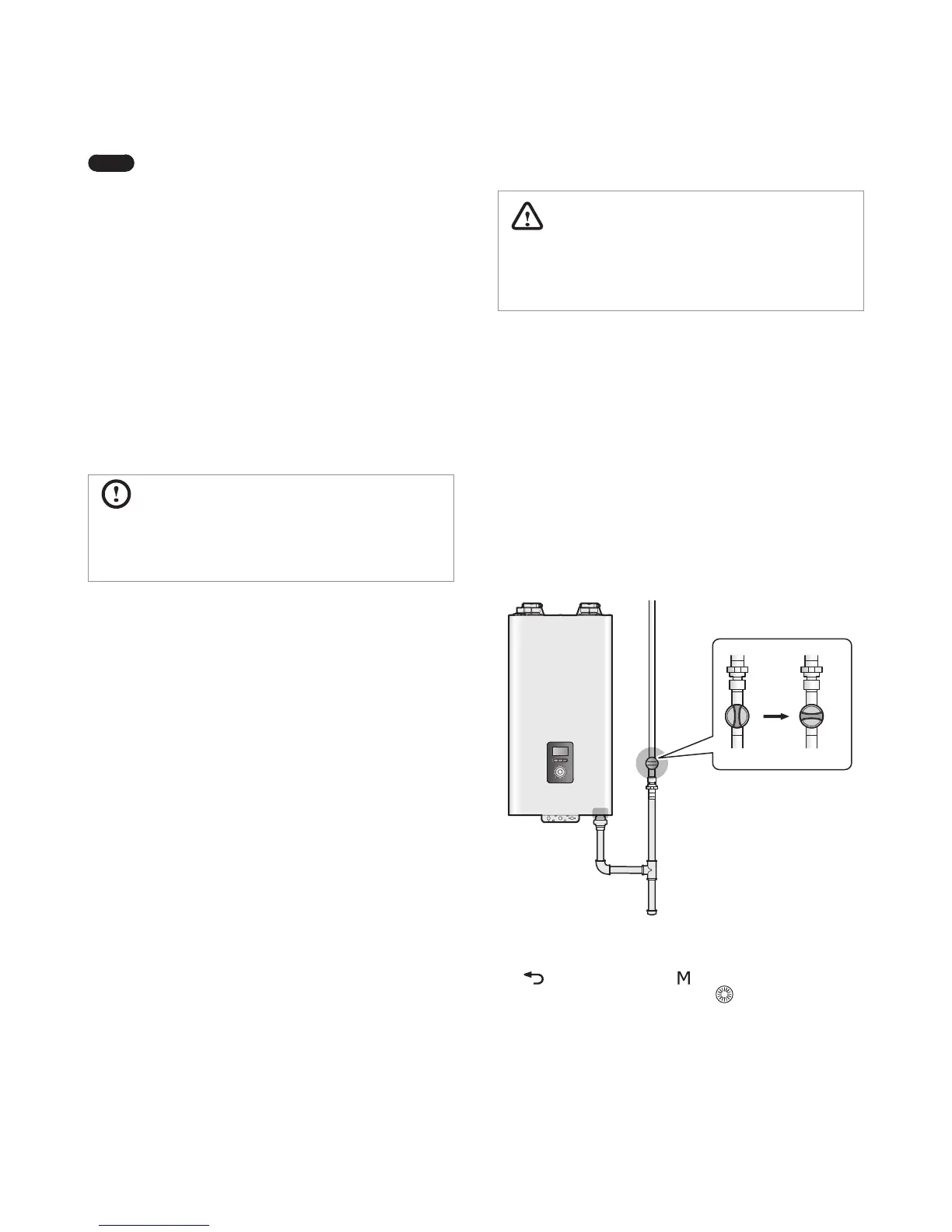

To measure the inlet gas pressure:

1. Shut off the manual gas valve on the gas supply line.

Gas Valve

Opened Closed

2. Turn on the boiler. On the front panel, press the Back button

( ) and the Menu button ( ) simultaneously for 3 seconds,

and then rotate the Command dial (

) to move to “7. Special

Operations”.

Loading...

Loading...