30 Installing the Water Heater

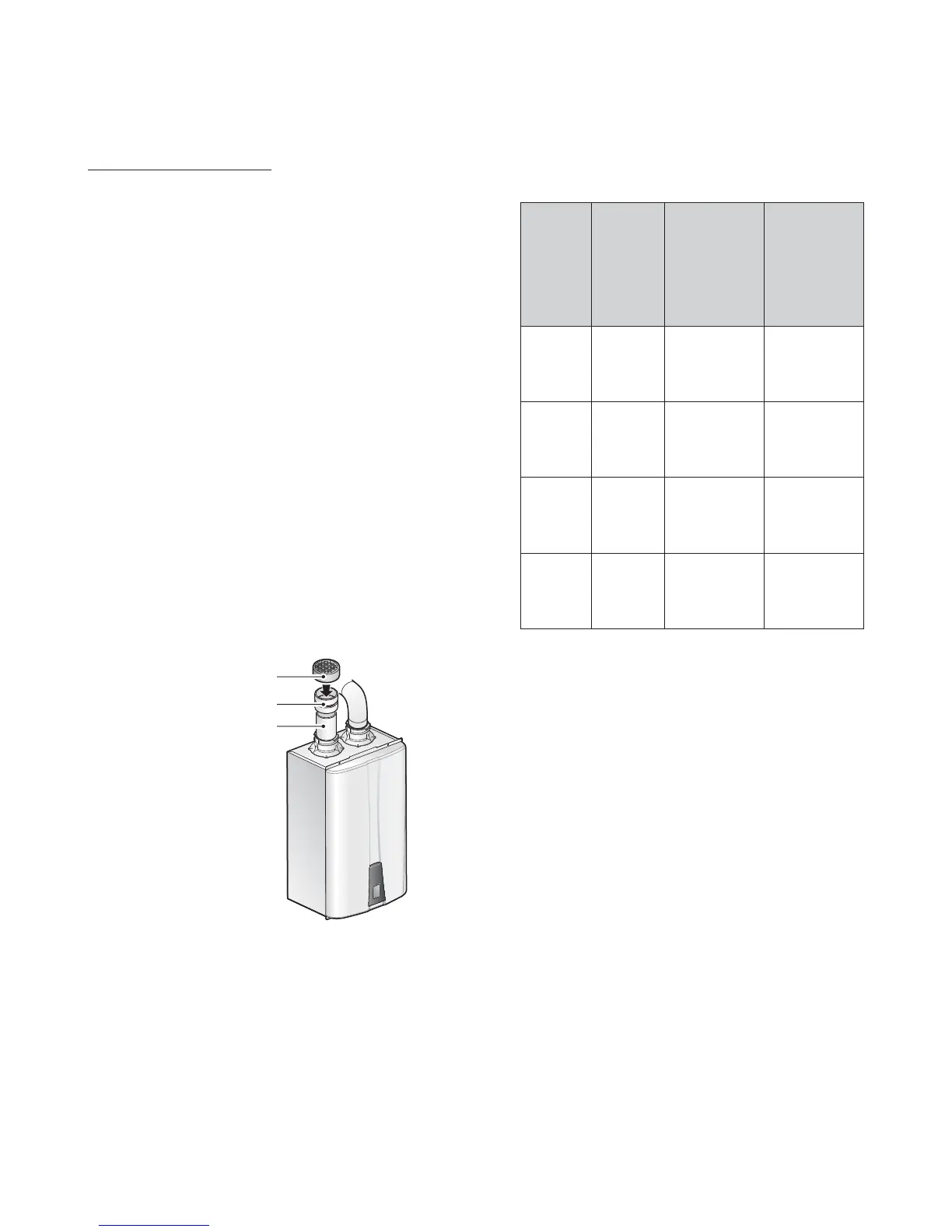

2. Provide two openings to allow for circulation of combustion air

as specified by ANSI Z223.1/NFPA 54 or CAN/CGA B-149.1:

Maximum

Input

(BTU/H)

Outdoor

make up air is

provided,

a minimum

free area of

1 in

2

per 4,000

BTU/H

Indoor make

up air is

provided,

a minimum

free area of

1 in

2

per 1,000

BTU/H

NPE-150S

120,000

30 in

2

10 in (W) x 3 in

(H) or 6 in

round

120 in

2

11 in (W) x

11 in (H)

NPE-180A

NPE-180S

150,000

40 in

2

10 in (W) x 4 in

(H) or 7 in

round

150 in

2

12

1

/

4

in (W) x

12

1

/

4

in (H)

NPE-210A

NPE-210S

180,000

45 in

2

10 in (W) x 5 in

(H) or 8 in

round

180 in

2

13

1

/

4

in (W) x

13

1

/

4

in (H)

NPE-240A

NPE-240S

199,900

50 in

2

10 in (W) x 5 in

(H) or 8 in

round

199 in

2

14

1

/

4

in (W) x

14

1

/

4

in (H)

Non-Direct Venting (Single Pipe)

If, at any time, the installation location could experience negative

pressure, there is a possibility of back drafting cold air through

the water heater’s heat exchanger. This situation could lead to

the freezing of the heat exchanger and malfunction of the water

heater.

However, building codes in most jurisdictions disallow negative

pressures in residences. In a home with a well-balanced air supply,

the heat exchanger should not be in danger of freezing. Because

the cause of back drafting is not considered a manufacturing

problem, any freezing damage which occurs from back drafting

will not be covered by the Navien warranty. If there is any question

about the possibility of back drafting in the installation location,

use a direct venting system for the water heater.

When installed in a manufactured home (mobile home), all

combustion air must be supplied from the outdoors as described

on page28.

When using non-direct venting, maintain non-direct vent

clearances shown on page31 as required by ANSI Z21.10.3 and

the National Fuel Gas Code, ANSI Z223.1/NFPA 54, and CAN/

CSA B149.1 Natural Gas And Propane Installation Code.

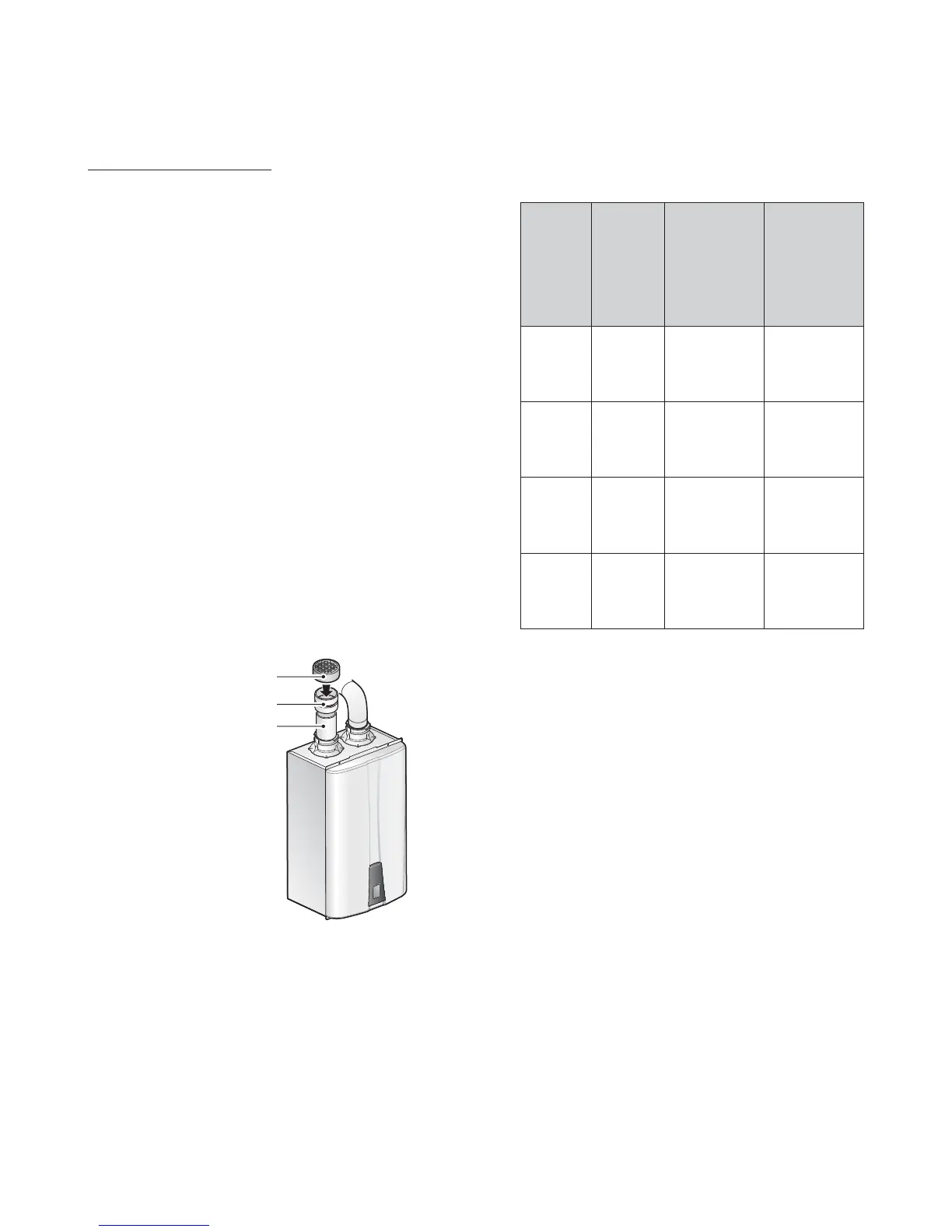

To use non-direct venting for the water heater:

1. Insert the termination end cap into the intake air duct. Do not

glue the end cap, to allow for easy removal and cleaning of the

cap.

Vent termination cap 2 in

Coupling 2 in

Pipe 2 in

Loading...

Loading...