S - Vacuum Cleaners

7Troubleshooting

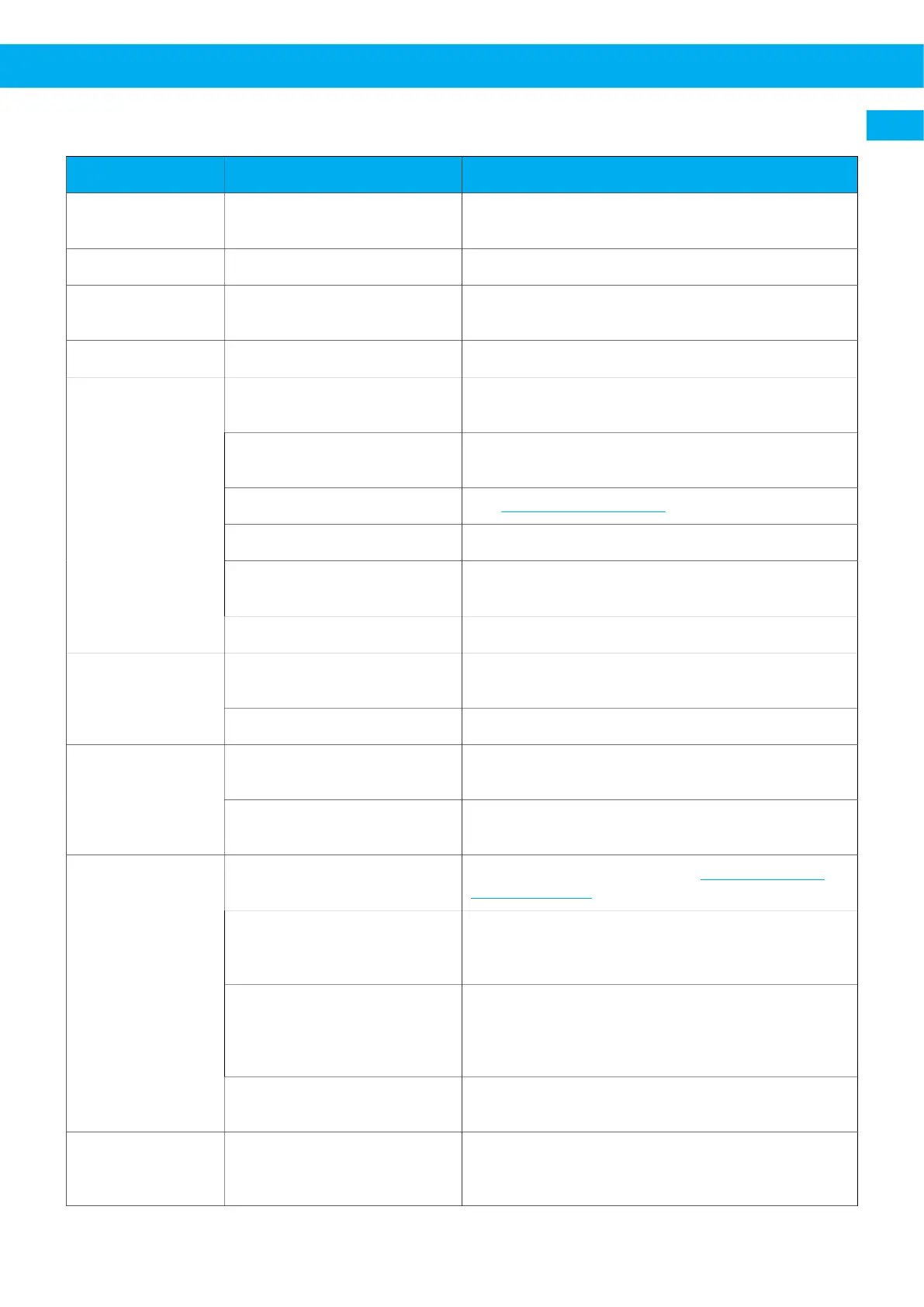

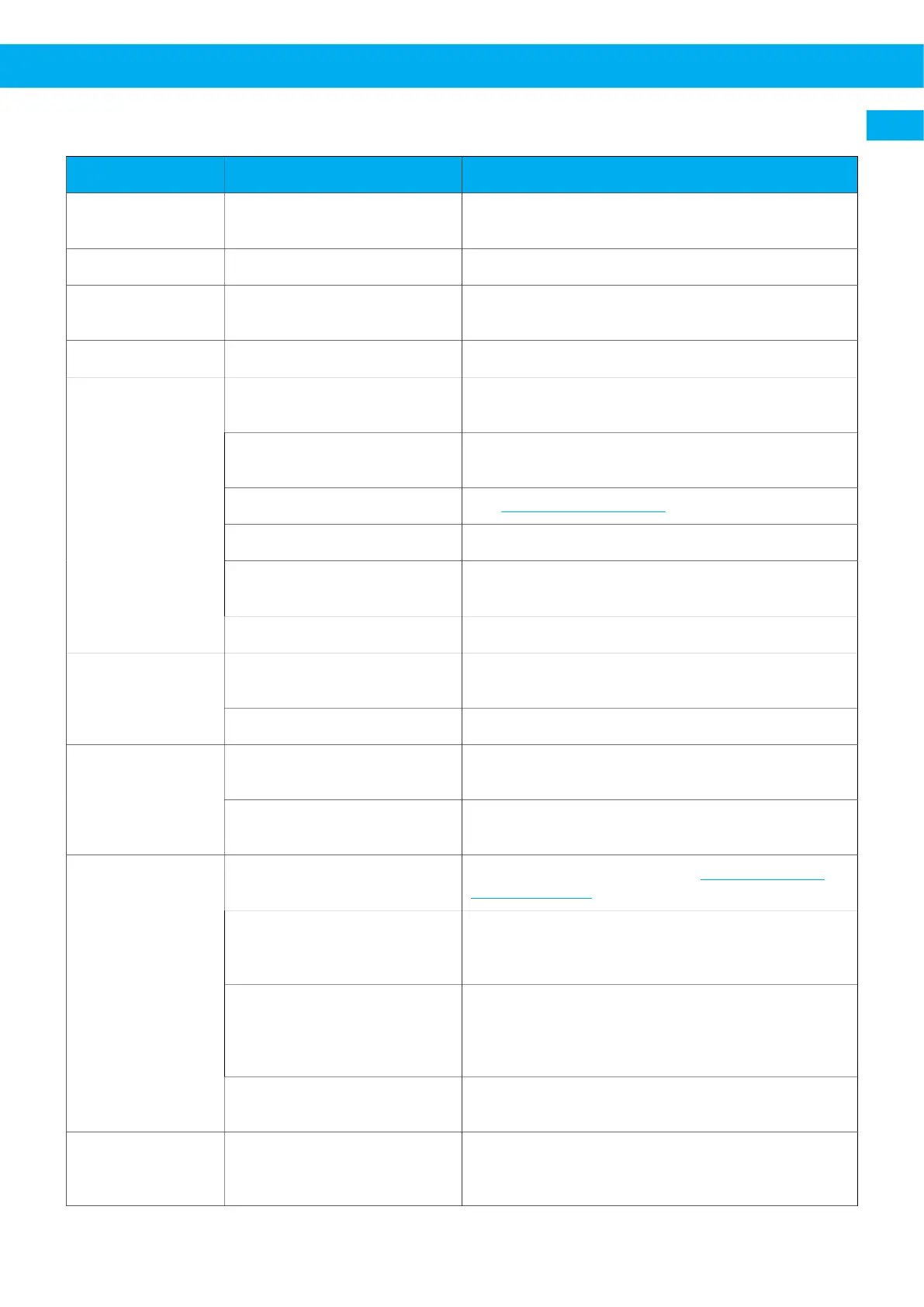

Problem Fault Solution

The motor will not

start

Electrical supply not connec-

ted.

Connect the electrical supply.

Power switch or cable defect. Contact the distributor.

Radio noise suppression card

defect.

Contact the distributor.

Motor protection activated. See "Motor protection activated".

The switch is not completely

turned on.

Turn the switch on.

Clogged suction hose or inlet. Disconnect the suction hose. Turn and suck in the op-

posite direction. If still clogged, unclog it with a rod.

Clogged filter. See Chapter6Maintenance.

Leaking suction hose. Replace the suction hose.

Leaking gaskets. Remove and replace damaged neoprene gaskets.

Use suitable two-component glue.

None or bad suc-

tion capacity.

Discharge valve open. Close valve.

Filter missing, defect or

wrongly installed.

Check the filter and replace it if necessary.Dust in the exhaust

air.

Filter defect Change filter.

Leaking gaskets. Remove and replace damaged neoprene gaskets.

Use suitable two-component glue.

Abnormal noise

level.

Sound absorbing material de-

fect.

Dismantle the silencer hood and remove dirt. Replace

damaged silencing material, if necessary.

Power outage. Reset the motor protection. See Section5.2Reset

motor protection.

Restricted or no airflow. Prevent overheating by ensuring that a flow of air

passes the fan. Make sure hoses, and the fan’s inlet

and outlet are not blocked.

Motors rotating in the wrong

direction.

Start the fan briefly, check the direction of rotation.

Impeller rotation must match the arrow on the fan

housing. If it does not, switch the phases L1 and L3

for three-phase operation.

Motor protection

activated

Ball bearing temperature

sensor activated.

See "Ball bearing temperature sensor activated".

Ball bearing tem-

perature sensor ac-

tivated.

Ball bearing temperature too

high.

Listen for abnormal noise from the fan. If there is ab-

normal noise, contact the nearest authorized distrib-

utor or Nederman service for technical advice.

EN

23

Loading...

Loading...