NS20A & NS20N Heavy Duty Gun Page 7 Revision 1.20 2/19/08

SEQUENCE OF OPERATIONS

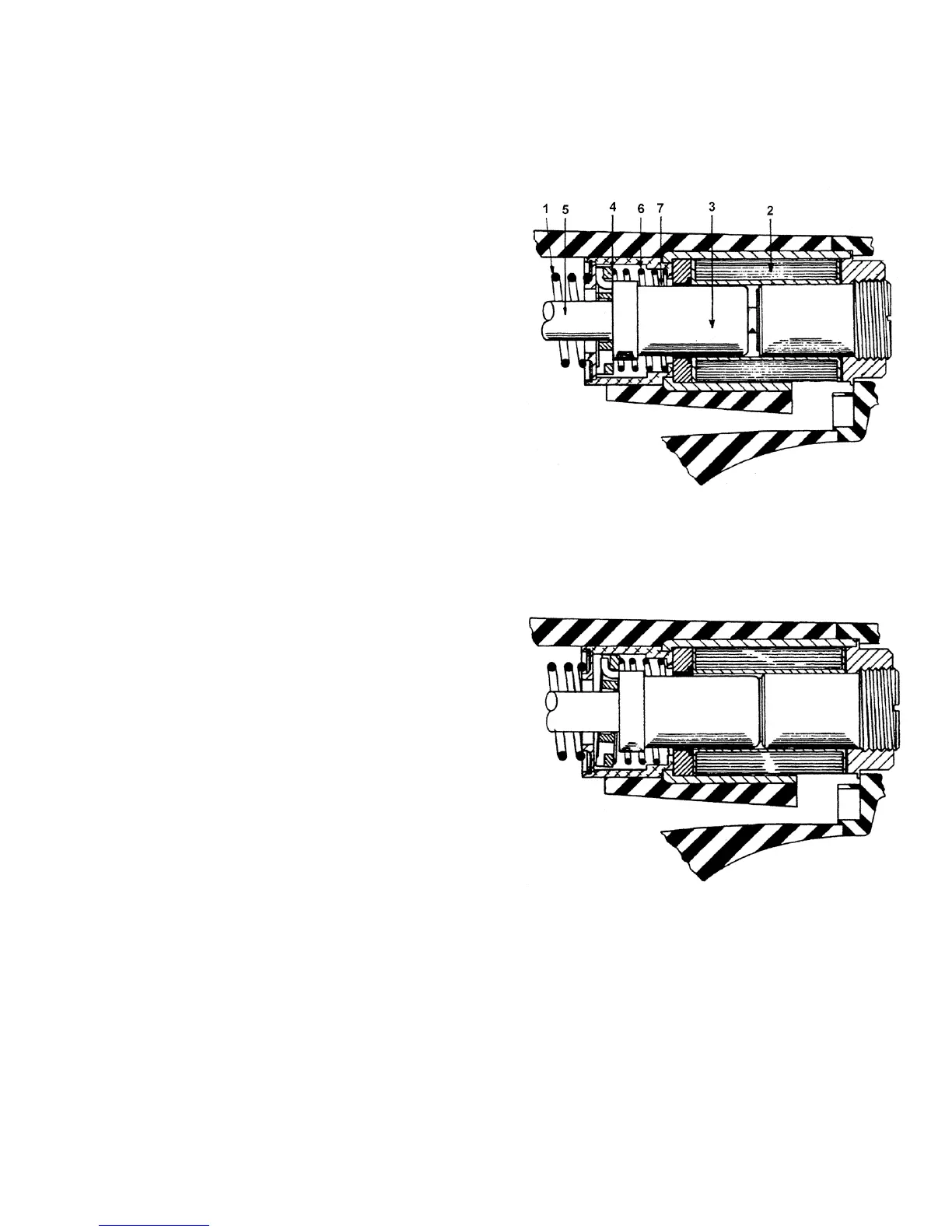

Welding Gun

1. Mainspring (1) is partially compressed and

lifting rod (5) slides through lifting ring (4)

when the gun is placed in weld position as the

plunge is taken up.

2. Pressing gun trigger button energizes gun coil

(2).

3. The gun coil (2) pulls back the movable core

assembly (3), causing the lifting hook of the

movable core assembly to lock the lifting ring

(4) on the lifting rod (5).

4. At the same time, the lifting ring spring (6) and

core spring (7) are compressed.

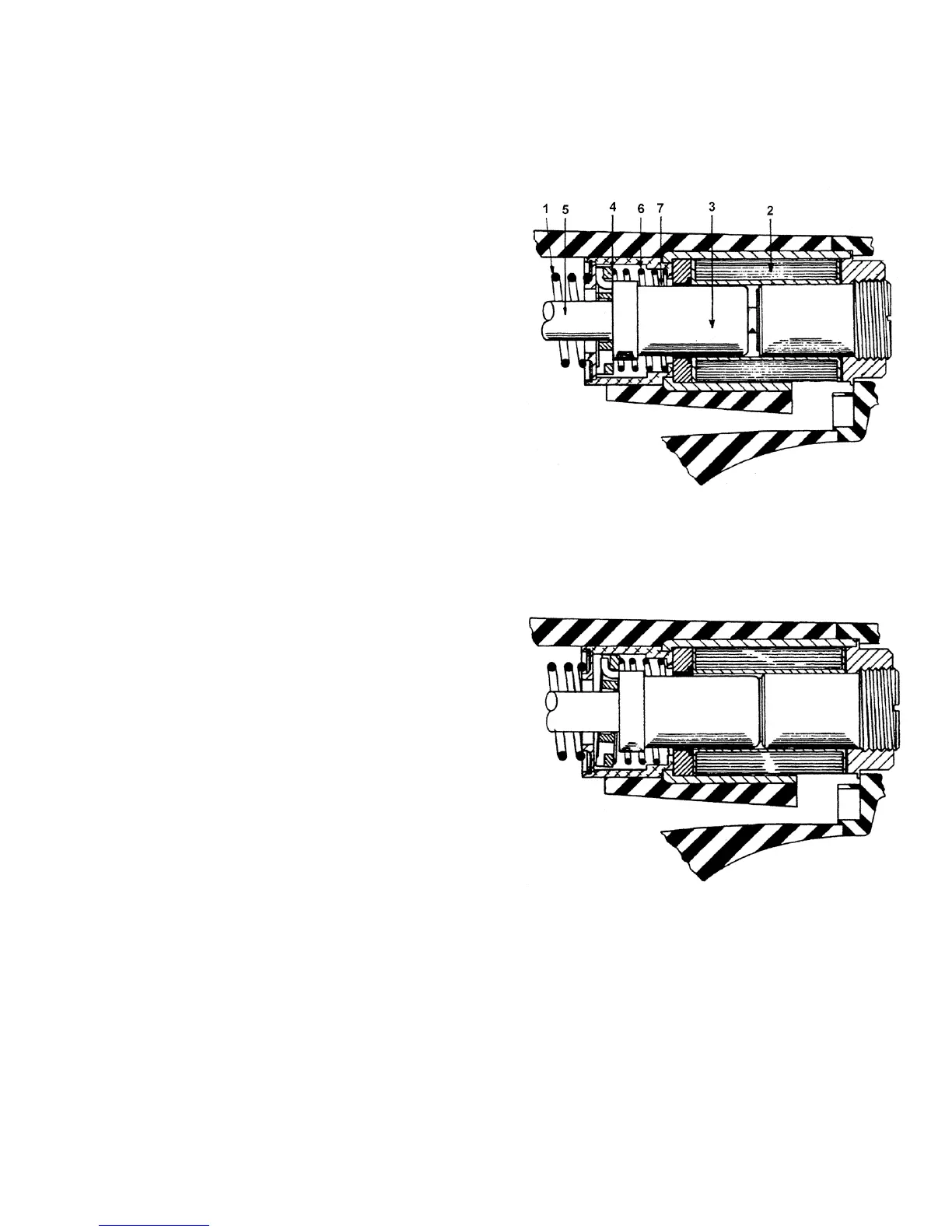

5. The cocked ring locks on the lifting rod, and

the movable core assembly "lifts" or pulls back

the entire assembly, including the chuck and

stud (Figure 6).

6. When the stud is "lifted" from the work, an arc

is initiated.

7. The assembly remains "lifted" for a preset weld

time.

8. At the end of this time period, the gun coil (2)

is de-energized.

9. The movable core assembly (3) is returned to

normal position by the core spring (7).

10. The lifting ring (4) is uncocked by the lifting

hook and lifting ring spring (6).

11. The mainspring (1) returns the assembly to

normal position, and this action “plunges” the

molten end of the stud into a pool of molten

metal on the base plate, thus completing the

weld.

Figure 5: Gun mechanism in normal

position

Figure 6: Gun mechanism in lifted position

Loading...

Loading...