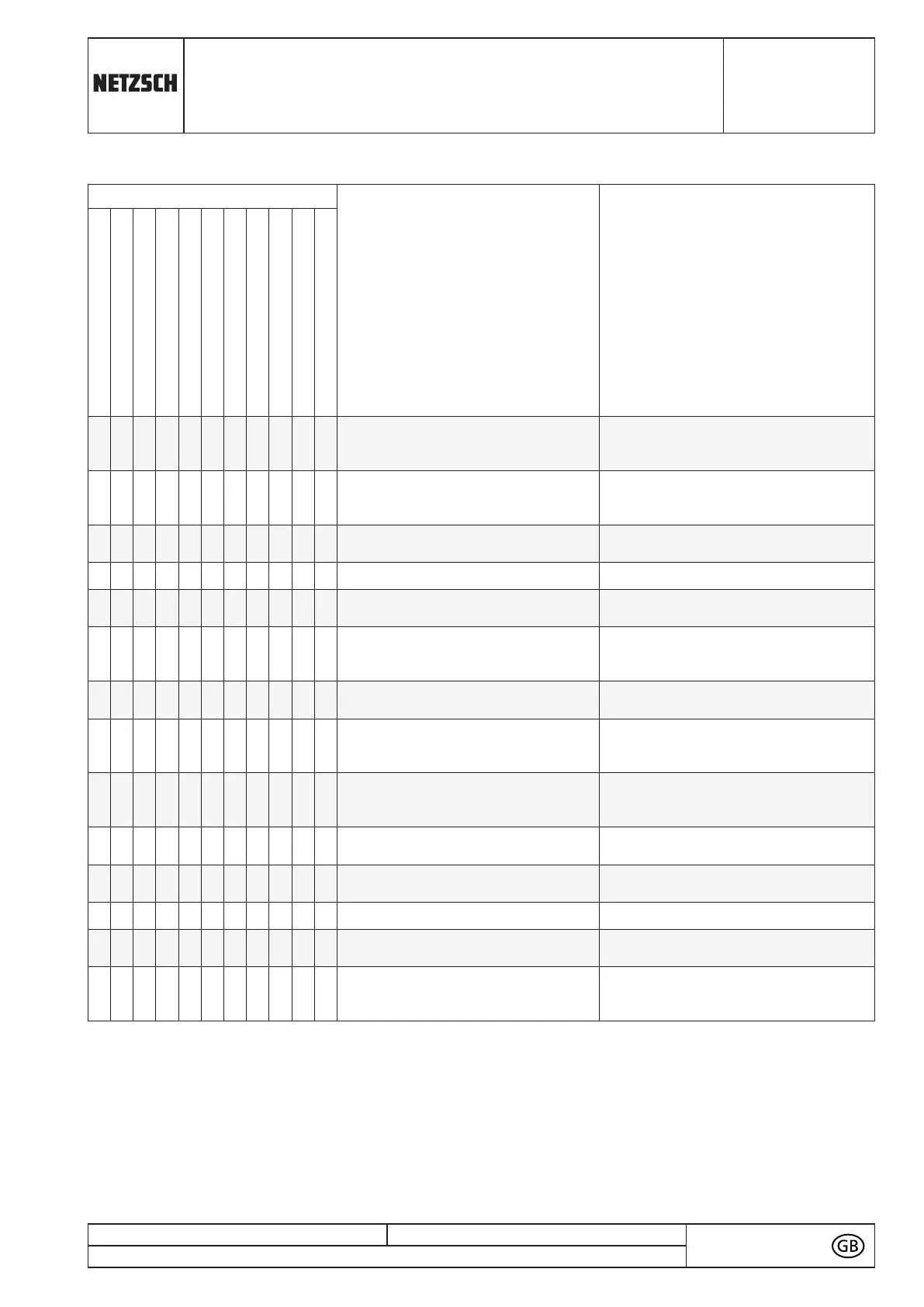

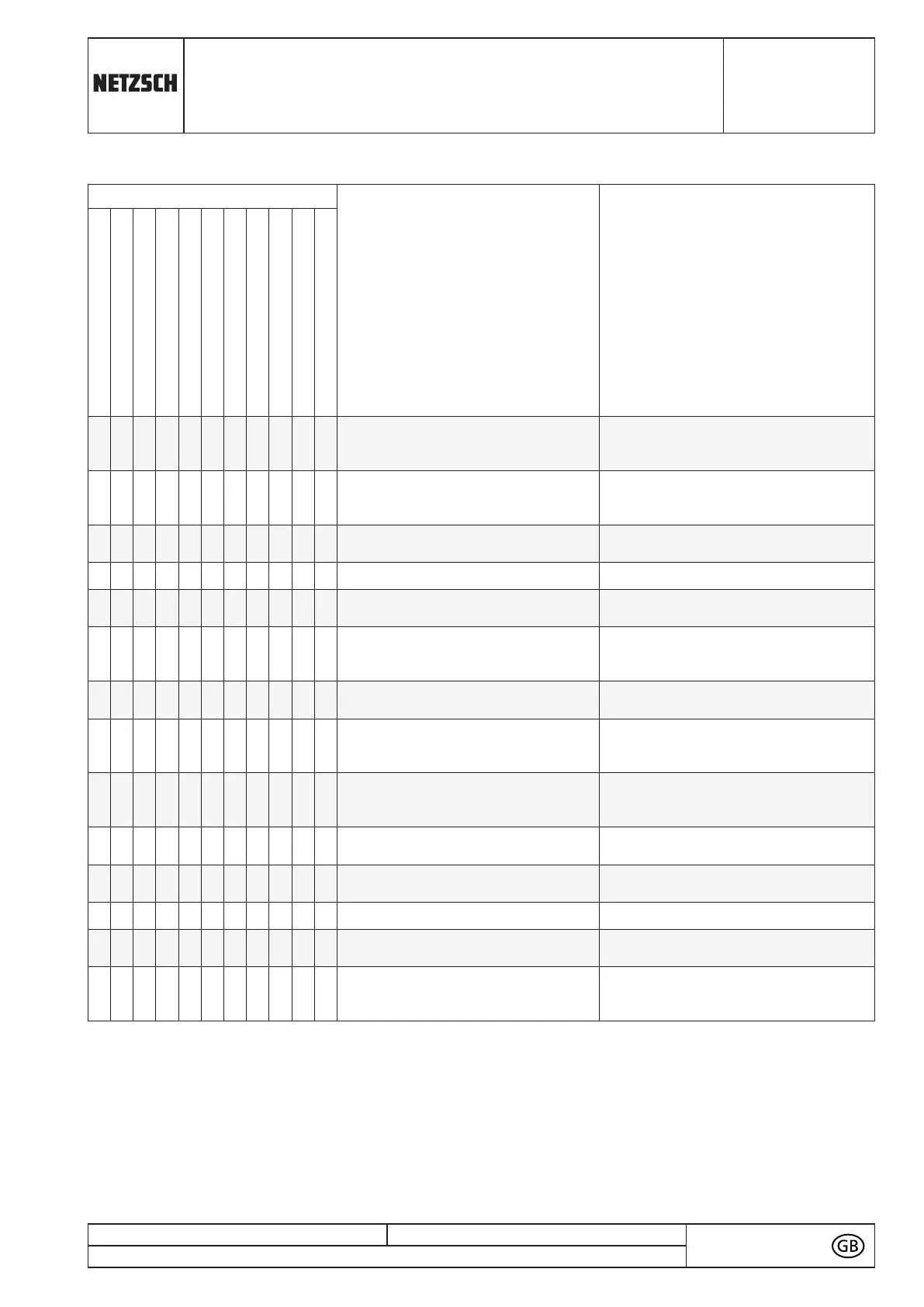

8 TROUBLE

-

SHOOTING AND

REMEDYING

PAGE

8.1

issued: 17.07.2017 Revision: 5

text no.

08000-2/2

copy to:

Possible Problems

Possible Causes Remedy

The pump is no longer starting

The pump is no longer sucking

The pumped medium is too little

The pressure is too low

The pumped medium is unstable

The pump is running loudly

The pump is stuck

The drive is overloaded

The stator life time is too short

The rotor life time is too short

The shaft seal is leaking

x x x x x x

The stator material is brittle.

Fit a new stator. Check the liquid medium agrees

with order details; if necessary change the stator

material.

x x x x x

The rotor is worn out.

Change rotor, establish the cause. Wear and tear,

corrosion, cavitation; if necessary change to a

different material or coating.

x

The joints are worn out.

Replace relevant parts, carefully reseal and

lubricate.

x x

The pump and drive are not axially aligned. Re-align the unit.

x

The elastic element of the coupling is worn out. Use a new connection and re-align the pump.

x x

The roller bearings are destroyed.

Replace roller bearings, lubricate, reseal. At higher

temperatures observe the lubricant and the bearings.

x

The rpm is too high.

In the case of adjustable drives : lower the rpm. If

necessary change the drive.

x

The viscosity is too high.

Measure the viscosity and compare with order

details. If necessary adjust viscosity or change the

drive.

x

The specific weight of the medium is too high.

Measure specific weight and compare with order

details. If necessary adjust specific weight or change

the drive.

x x

The stuffing box is incorrectly tightened.

Service stuffing box according to page 7.4, if

necessary renew worn shaft.

x

The packing is not suited to the liquid medium. Replace fitted packing with another packing type.

x x

Mechanical seal: rotation is incorrect. Change electrical connection.

x

Mechanical seal: mechanical seal and mating ring

have failed.

Replace relevant rings with new ones.

x

Mechanical seal: elastomers damaged, swollen or

brittle.

Replace elastomers. Check whether the liquid

medium agrees with order details, if necessary

change material.

IPP - EN - EN_08000_20170712/3 - D8411276 - 4300003998 - 000100 - NPS - 00229929 N 2018-02-21 19:03:25

Loading...

Loading...