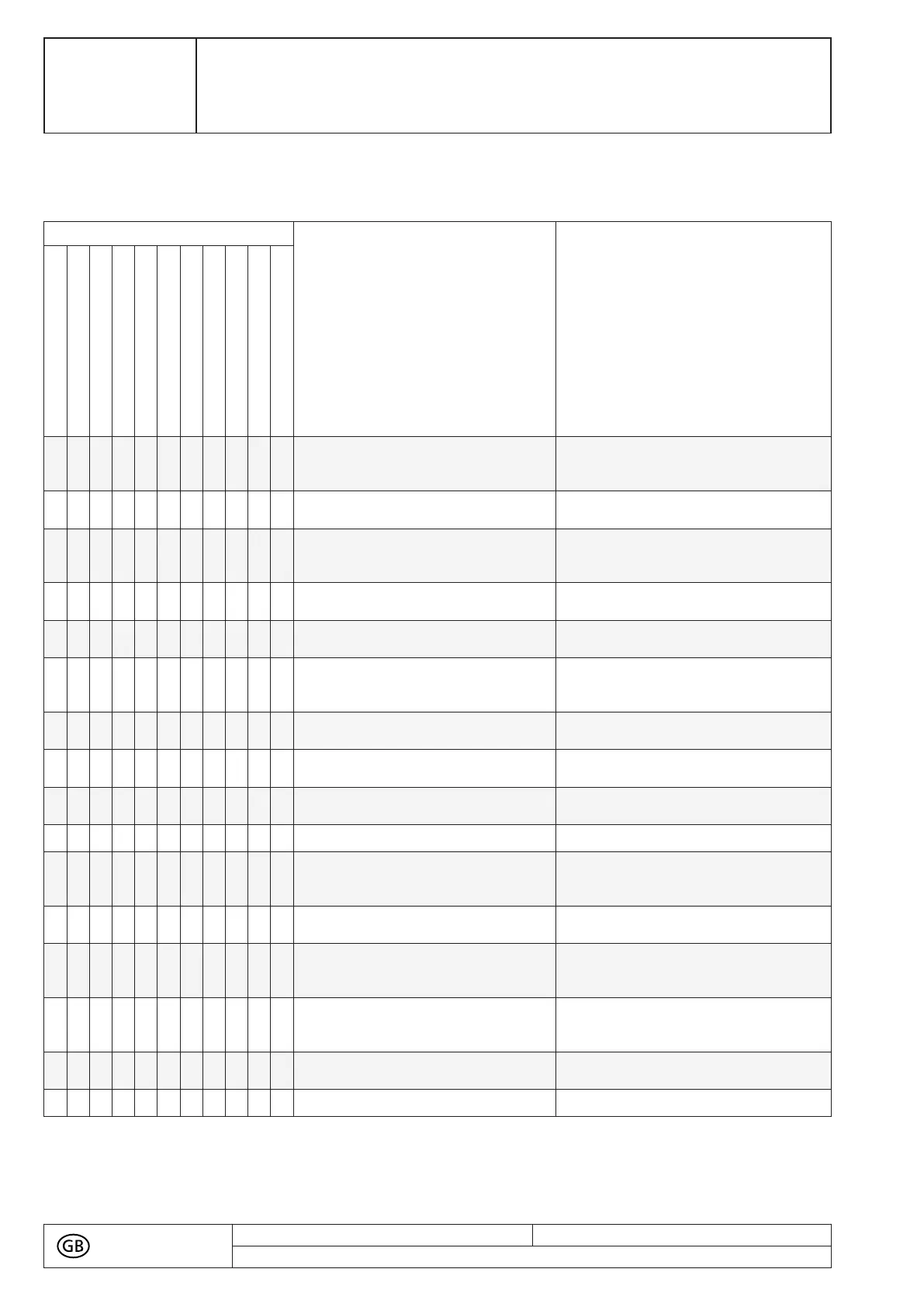

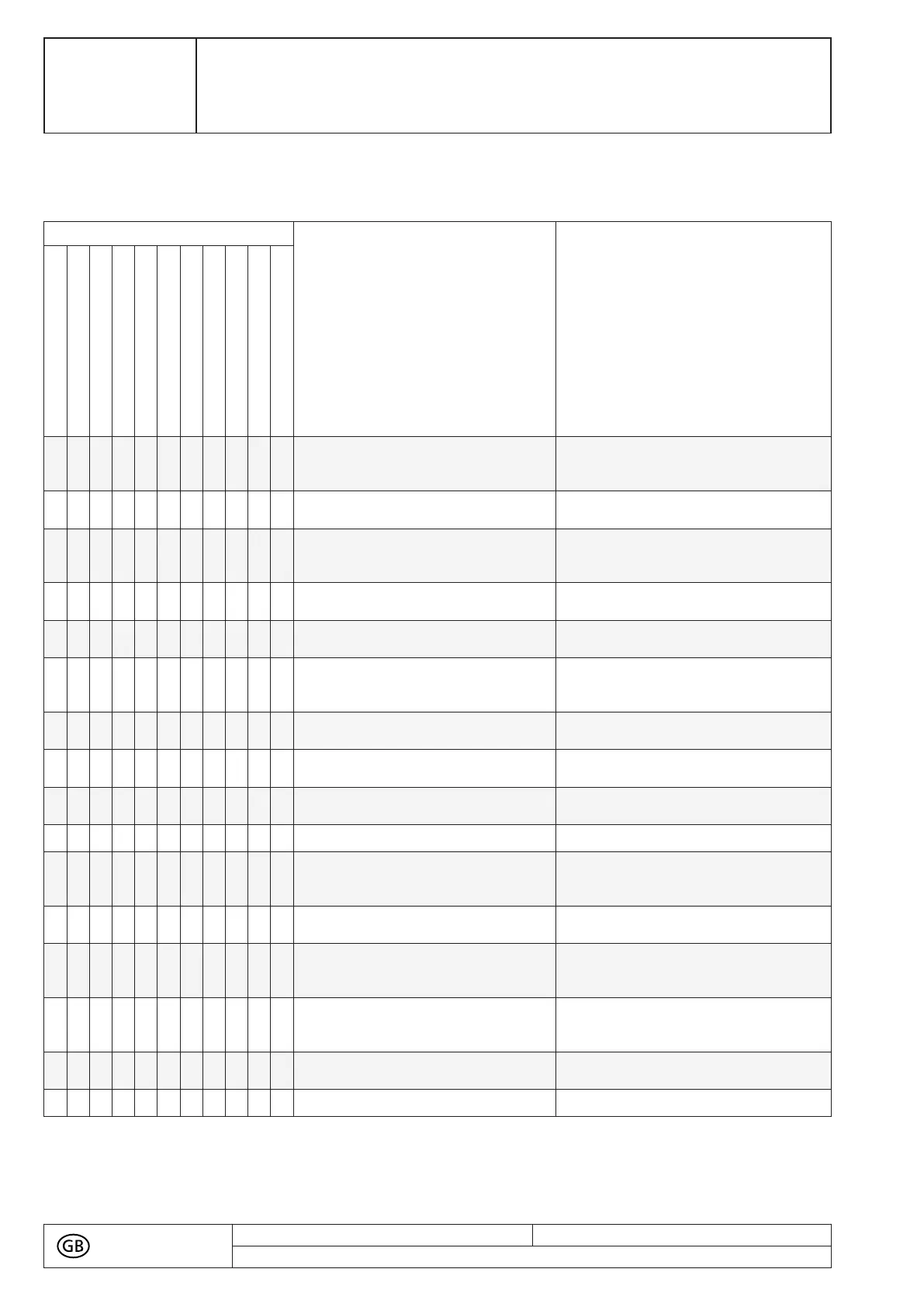

8 TROUBLE

-

SHOOTING AND

REMEDYING

PAGE

8.0R

text no.

R 08000-1/2

issued: 17.07.2017 Revision: 5

copy to:

Possible Problems

Possible Causes Remedy

The pump is no longer starting

The pump is no longer sucking

The pumped medium is too little

The pressure is too low

The pumped medium is unstable

The pump is running loudly

The pump is stuck

The drive is overloaded

The stator life time is too short

The rotor life time is too short

The shaft seal is leaking

x x

In new pumps or stators:

the static friction is too great.

Fill the pump up, then pump through manually using

a suitable appliance; if necessary use glycerine as

lubricant in the stator.

x x x x

The pump electrical equipment is not compatible

with the electrical supply..

Check order information. Examine electrical

installation (possibly 2 phase operation).

x x x x

The pressure is too high.

Measure the pressure with a manometer and check

against order details. Reduce the pressure or

change the drive.

x x x

There are foreign bodies in the pump.

Remove foreign bodies and eliminate possible

damage.

x x x x x

The temperature of the liquid medium is too high,

the stator is too ductile.

If the liquid medium temperature cannot be lowered,

use a reduced diameter rotor.

x x x x

The stator has swollen, the elastomer is not

compatible with the medium.

Check whether the liquid medium agrees with the

order requirements. Possibly change stator material.

x x x x

The solids content of the medium is too high and

leads to blockages.

Increase the liquid part of the medium.

x x x x x x

The liquid medium sediments or hardens when left

to stand.

Clean the pump and rinse through after each run.

x x x

There is air in the suction pipe.

Increase the suction liquid level, prevent turbulance

and air bubbles at the inlet.

x x x x

The suction pipe is leaking. Check seals and tighten pipe connections.

x x x x

The shaft seal is leaking.

Stuffing box: tighten or renew. Mechanical seal:

renew seals, eliminate solid deposits.

x x

The rpm is too low.

In the case of adjustable drives: increase the rpm. If

necessary change the drive.

x x x

With reduced diameter rotors: operating

temperature has not been reached.

Pumpe (Stator) erst auf Betriebstemperatur

erwärmen.Warm up the pump (stator) to operating

temperature first of all.

x x x x x x

The suction is too great or pressure too low

(cavitation).

Decrease suction resistance, lower the temperature

of the liquid medium, install the pump at a lower

location.

x x x x x x

The pump is running dry.

Fill up the pump, provide for dry running protection,

move the pipes.

x x x x

The stator is worn out. Replace with a new stator.

IPP - EN - EN_08000_20170712/2 - D8411276 - 4300003998 - 000100 - NPS - 00229929 N 2018-02-21 19:03:25

Loading...

Loading...