5.

A(tiustment/tQ!fl

~4

Change

of Stitch

Length

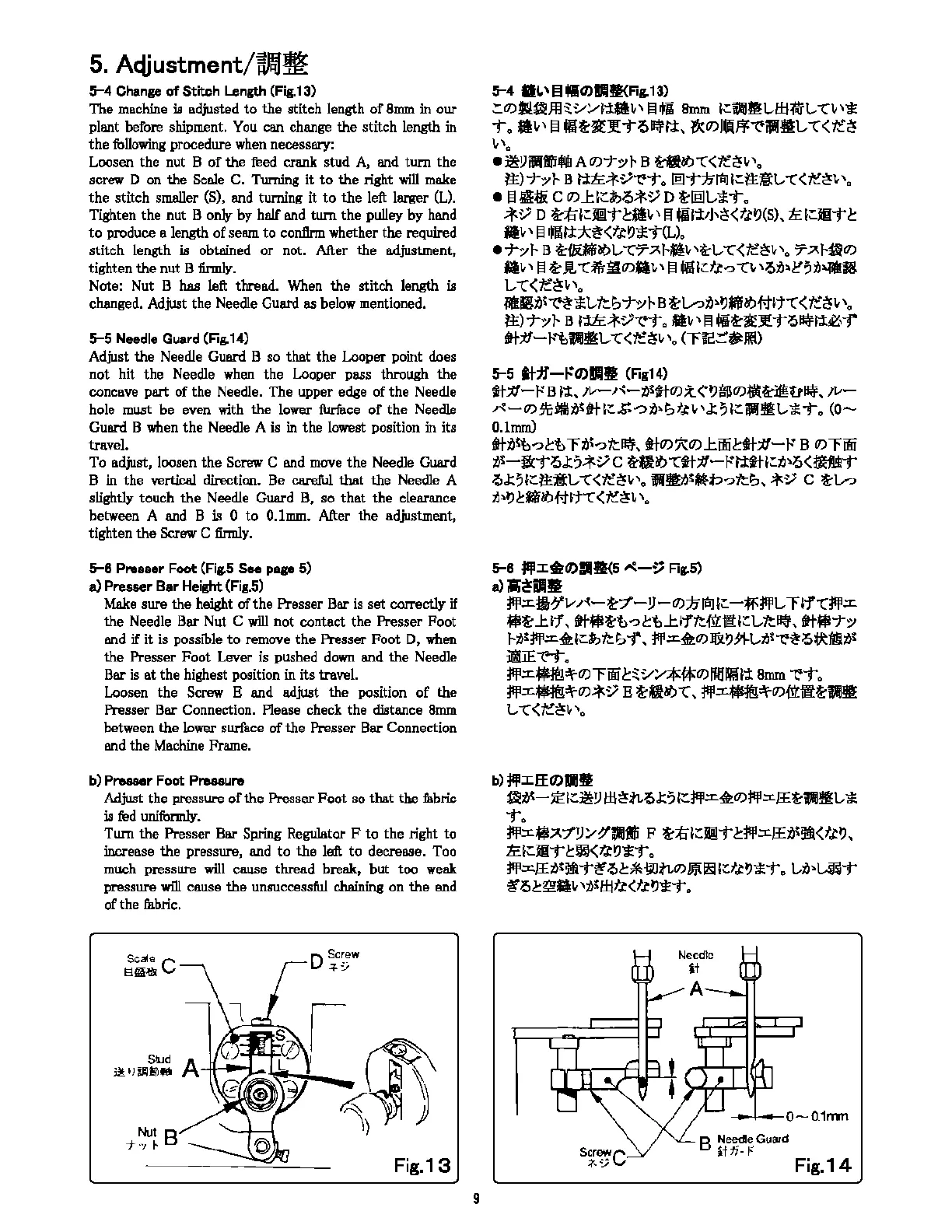

(Fig.13)

The

machine is adjusted

to

the

stitch length

of

8mm

in

our

plant before shipment.

You

can change

the

stitch length

in

the

following procedure when necessary:

Loosen

the

nut B

of

the

feed crank

stud

A,

and turn the

screw

D on

the

Scale

C.

Turning

it

to

the

right

will

make

the

stitch smaller

(S),

and turning

it

to

the

left larger (L).

Tighten

the

nut

B on]y by half and turn

the

pulley

by

hand

to

produce a length

of

seam

to

confirm whether

the

required

stitch length is obtained

or

not. Aft.er

the

adjustment,

tighten

the

nut

B firmly.

Note: Nut

B has left thread. When

the

stitch length is

changed. Adjust the Needle Guard

as

below mentioned.

~5

Needle

Guard

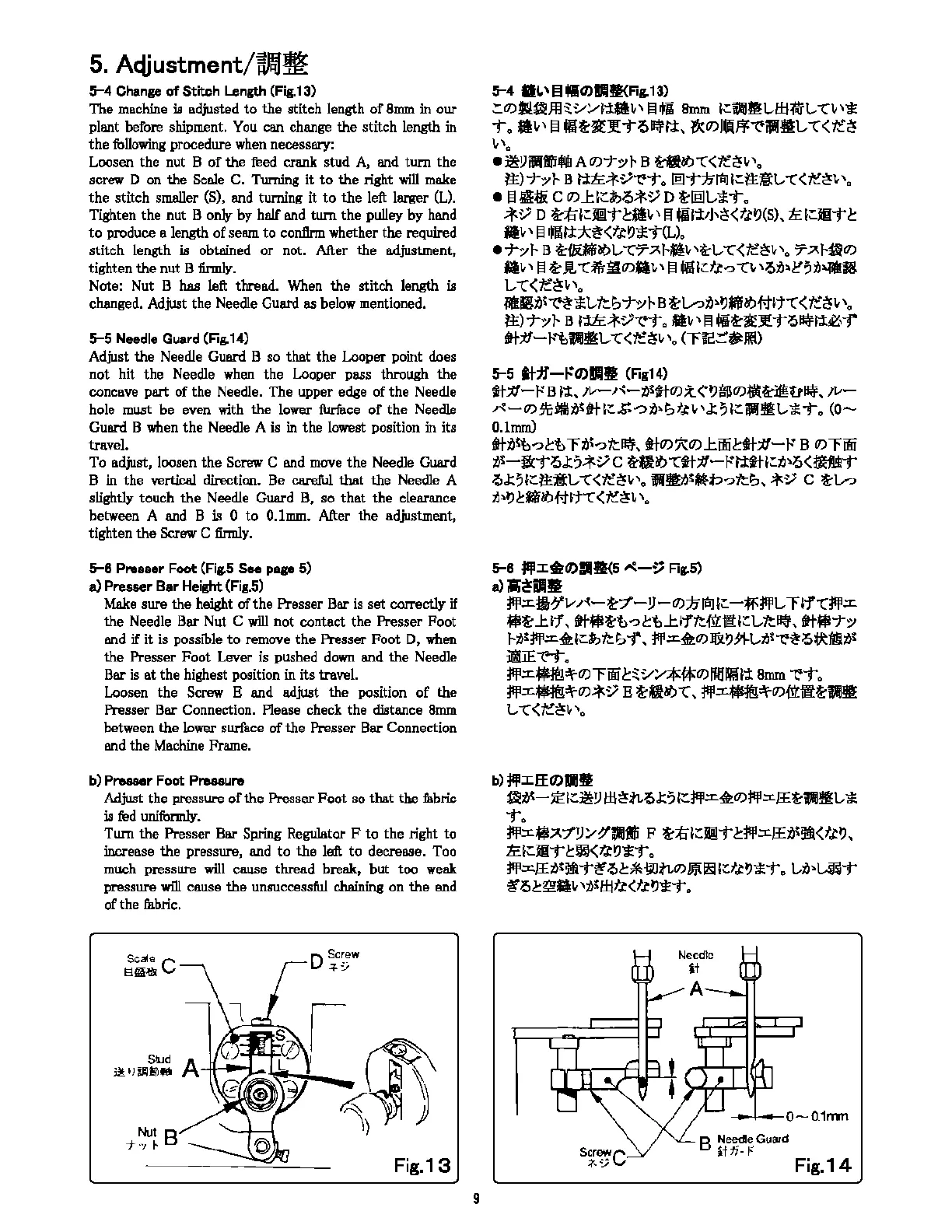

(Fig.14)

Adjust

the

Needle Guard B

so

that

the

Looper point does

not

hit

the

Needle when

the

Looper pass throUgh

the

concave

part

of

the

Needle.

The

upper edge

of

the

Needle

hole must

be

even with

the

lower furface

of

the Needle

Guard

B when

the

Needle A is

in

the

lowest position

in

its

travel.

To

adjust,

loosen

the

Screw C and move

the

Needle Guard

B

in

the

vertical direction. Be careful

that

the

Needle A

slight]y touch

the

Needle Guard

B,

so

that

the

clearance

between A and B is

O

to

0.1mm.

After

the

adjustment,

tighten

the

Screw C tinnly.

~6

Pntaaer

Foot

(Fig.5

See

pap

5)

a)

Presser

Bar

Height

(Fig.5)

Make

sure

the

height of

the

Presser Bar is

set

COJTectly

if

the

Needle

Bar

Nut C will

not

contact

the

Presser Foot

and

if

it

is possible

to

remove

the

Presser

Foot

D,

when

the

Presser

Foot

Lever is pushed

down

and

the

Needle

Bar is

at

the

highest position

in

its

travel.

Loosen the Screw B and ad.just

the

position

of

the

Presser Bar Connection. Please check

the

distance 8mm

between

the

lower

surface of

the

Presser Bar Connection

and

the

Machine Frame.

b)

Presser Foot Pressure

Adjust the pressure

of

the

Presser

Foot

so

that

the

fabric

is

fed

uniformly.

Turn

the

Presser Bar

Spring

Regu]ator F to

the

right to

increase

the

pressure, and to

the

left

to

decrease.

Too

much pressure

will

cause thread break,

but

too weak

pressure will cause

the

unsuccessful chaining

on

the

end

of the mbric.

Sca

le C

S!Ri~

Nut

B

-r·

:;

I-

Fig.13

9

~•

a1.,

l!l

•0•1f<Fig.1

a>

~O)IU~ffl~~YJ'i:.1,'

El

.I

8mm

l.:1,\Hlt.A±i7-G't..

"'(1,Yi

To

fii,,

El

-~~J!To~tJ:,

*17)JU(J¥~111tt..

--c<tt-ts

\,\,

•~!Jillffifdl

A

0)77}-

B

ait~-C<te-ts1,,o

1±)

'To/

t-

B t.tft-*

~~To

~Tjj~

l.:&•t..

--C

<

r.:~v

'a

•

B•tt

C

17)J::l::ib.S*~D

~~L-*To

*~

D t,til::!11--t~ai,'

I!!

tll'11J,~<t.ttJ(S),

ftl::Jll--t.!::

til1i,

El

iMtJ:*~<tl~t*"'t<L)o

•1"o/r

B

~flil'laf)L,

--C7Af-ltt,,t,l,

--C<te~1,,o

7AJ-Ql7)

a1i, B

~

.i.

-c~:i1.11)a1,,

B Cll.:t.t--:>--C"''°""t°?ti~•

l,

--C<'fe~l,

\o

illMil~~~:fl,'ft~-ro/l-B~L--?tJi.tJ.W~#lt-C<tt~1,\,

i±)"To/r

B 1'1ft*V~T

••

1,,

El

·~~J!To~l'i:~,-r

ttP-t-~

at!!IL-

--c

<tt~1,

'o

(rE.::.'•

JffO

~5

ttfl-i:0••

(Fig14)

ttP-l-'

B

•-1,

1v-.1~-t,Sftl1)

*.

~tJi617)•~tr~,

1v-

r~-11)

.9f:J4UStH::~-?tii.lI,t.n

,.,t;

l::!1.l!RL-*T

O

(0-

0.lmm)

ttti~?.!::b

ril~?'ft~,

ftl7)1cO)J::ffi~;t/-f: B

17)""fffi

t,s-!fcTo.t;*~

c

~ao--cttff-t:t.tttl::ti\o<BT

.S.t::it::1±B:L---C<tt~1,,

0

flf!1)S.b?'ft~,

*V

C ~l--?

tJ'-tJ~-ab#lt--C

<~~l,

'·

~6

jip:c*O>IHIC5

~-~

Fig.5)

a)jlj~--

jlp;r.it~v .1~-~7"-!J-17)JJ~t.:-~¥Pt...

ri1--c¥P;r.

-~

J::lf, tt•~b?.!::bl:lf'ftttt:IU::t..'ft~,

tt•-ro/

f-tJ!jlp;r..f;::cb'ft~-r,

jlp:::c..O)J&t;)~L,tJS~~o~fllit,i

iliE--C-t.,

jlp:::c.·#}~17)rffi.!::$;~Y*f*O)IJU~l-;t

8mm

~To

¥P:::c.n~l7)*vE~•~--c,~:::c.n~l7)~•~••

l.,

--C<'fe~l,

'o

b)

jlp:cEEO>II•

~~-~·=~!J

l±i~.tL,o.t;1::¥11:::c.~11)jlp:::c.J£~al!!IL-*

To

jlp:::c..A

:l°!JY

!/1,IJtli

F

~:;{:jl;::Jl!1T

.!::jlp:::c.J£t,~!Mt<

flt),

ftl.:fflT

.!::ffil<t.ttJj:T

Q

jlp:::c.J£t,S!Mt--t~

,o.!::*Wti,17)

ffi

ml

1::tttJ*T o

t..t>i.

L-ftT

~Q~~-1,,t,tlfitt<fttJ°*T·

---

-o-o.1rrm

B

Needle

Guard

if

;Ii-

t-'

Fig.14

From the Library of Superior Sewing Machine & Supply LLC

Loading...

Loading...