5.

A(tiustment/i,IJ!i

5-

7 Thread T

enaion

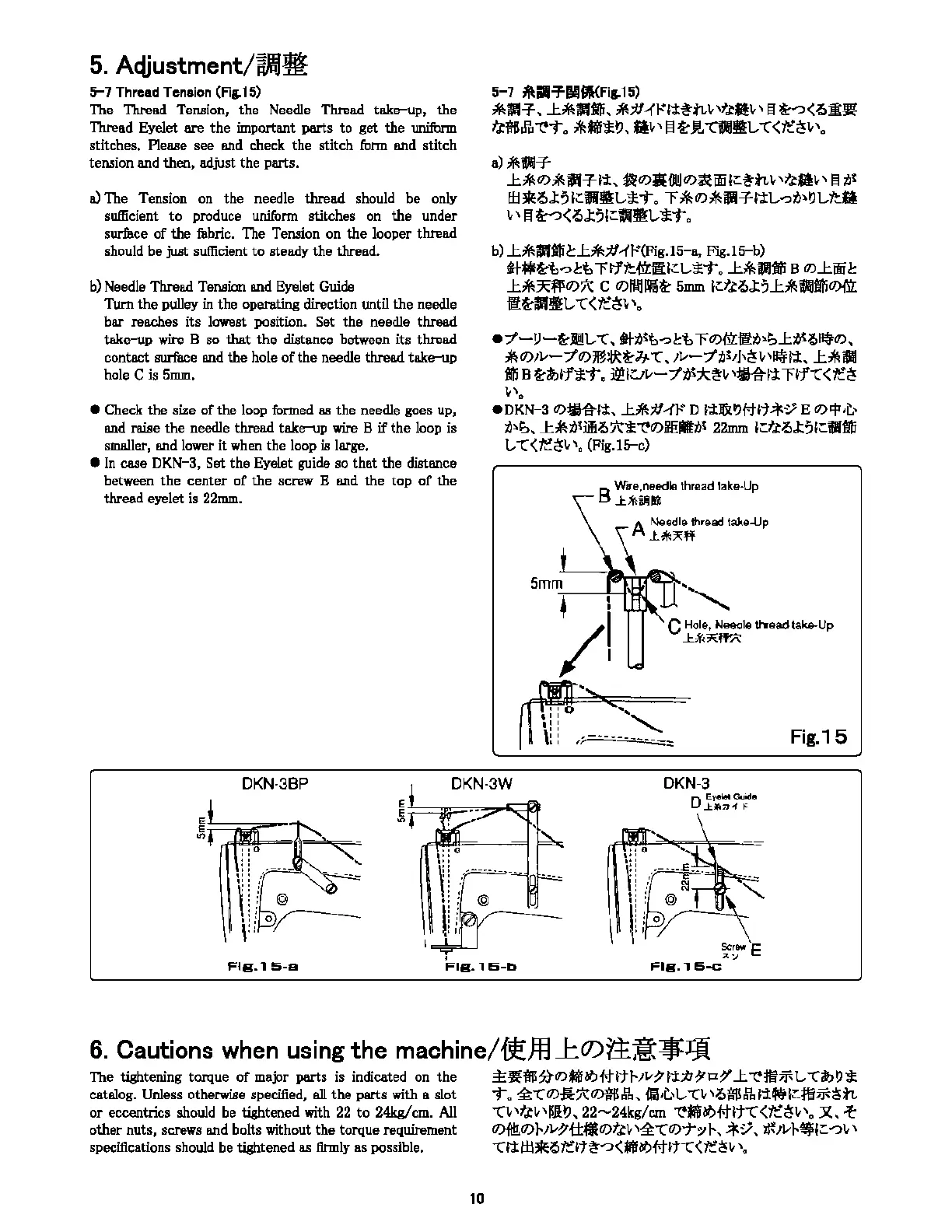

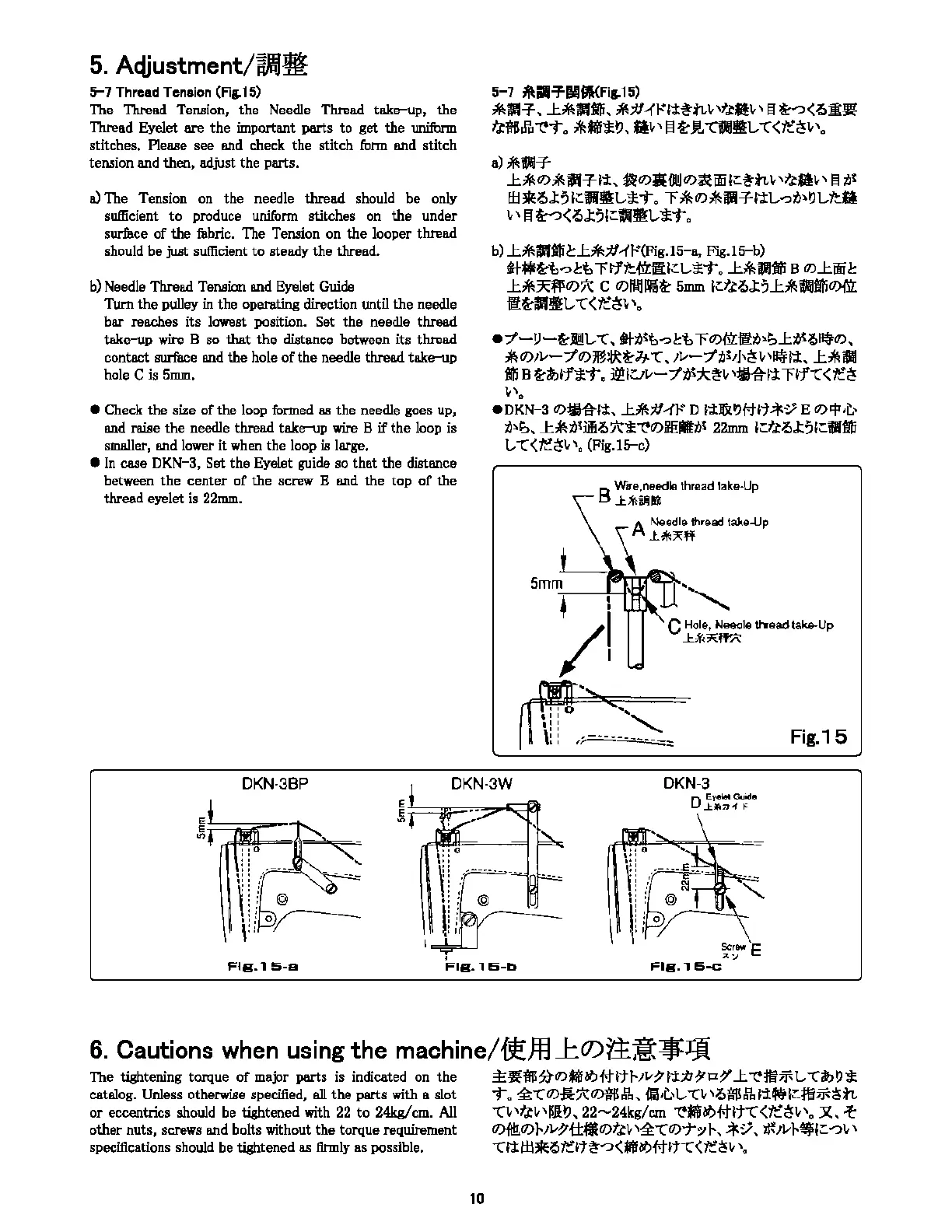

(Fig.15)

The Thread Tension, the Needle Thread take-up, the

Thread

Eyelet are

the

important parts

to

get

the

uniform

stitches. Please see and check the stitch fonn and stitch

tension and then, adjust the parts.

a) The Tension

on

the needle thread should

be

only

sufficient

to

produce

uniform

stitches on

the

under

surface

of

the fabric. The Tension on the looper thread

should

be

just sufficient

to

steady the thread.

b)

Needle Thread Tension and Eyelet Guide

Turn the pulley in the operating direction until the needle

bar

reaches its lowest position. Set

the

needle thread

take-up wire

B so that the distance between its thread

contact

surface

and

the

hole

of

the

needle thread take-up

hole

C is

5mm.

• Check

the

size

of

the

loop

formed

as the needle goes up,

and raise

the

needle thread take-up wire B

if

the

loop is

slDll.ller,

and lower

it

when

the loop is large.

• In

case

DKN-3, Set

the

Eyelet guide so that

the

distance

between the center of

the

screw E and

the

top

of

the

thread eyelet is

22mm.

5-7 RtllTllfl~Fig.15)

*

IH·,

.1:*

If

Mi,

*;J-1'r

li~.t1,1,

,t,tfti.,,

f!

~~<

!>:BUIE

fliU~~To

*Mi*tJ,

fii,,

El

~R.

'"CPHIL:C<tt~lr'o

a)*PH·

J:*O)*l\'ITl'1, ~0)-fflljO)~'fiil;::~tt,1,,t.dlllr'

El

'!JS

!:fHl~-o.l::H;:\R!IIL:*T•

r *©*iM-rf~L,~il~tJL,ttfi

i.,,

I!!

r?<o.1:;1;::Jt!flt.,*--t.

b)

J:/AlllitJ:1*;J-1'f-:{Fig.l5-a,

Fig.15-b)

tt*ll~t>~tt> rtftti!ia,-:1.,*--t· J:*illffli e

O)J:'fii.!::

.1:*3cff©:t( C

O)fMJIWj~

5mm

laloJ::;.1:=*llliliti<l.>ilL

-~-fEL,

"(

<~~\,

\,

•::t-!J-~DL,

--c,

ttil~b~.!::t>

r©&fitiJi.;J:~o-©,

*0)1v-::t©~:1*~1J.

--c,

1v-::t;)t,J,~1,

,11{;1'1,

.1:*

118

fflj

B

~ib•f*T•

~lr.1v-:;t~1*~1, 'i.1-8-J:trlf--C<~~

11\.

eDKN-3 ©tl-8-1:t, .l:*;t!-1'¥ D

J:tJ&t.>t-t•t-*~

E

O)ip,t,,

~lo~,

.1:*tiimo~*~©ffilll»i

22mm

1;:.t.to.t%:::.1tfli

l,

"C'(~~i.,

'•

(Fig.15-c)

B Wire:needle thread

lake

-

Up

.l¼-~&'1!

A Needl9 thread t

ake

-

Up

J:,1'.~M

C Hole, t.Jeedle thread

lake-Up

l:.*~~f!M:

Fig.15

DKN-3BP DKN-3W

DKN-3

Di

~~

~i

d•

I

Flg.15-a

FIS.16-b

6.

Cautions when using

the

machine/ff!JflJ:.O)~~-l3l

The tightening torque

of

major parts is indicated on

the

catalog. Unless otherwise specified, all

the

parts with a slot

or

eccentrics should be tightened with

22

to

24kg/ cm.

All

other nuts, screws and bolts without

the

torque requirement

specifications should

be

tightened as

firmly

as possible.

10

.:E:J{tflHi-©Mi~M"ltt-,v?

1~:b

?'i:t?"

J:

~m~

t.,

--Cibl:J

*

Ta

~"(0)-jt:,CO)t,l)iro,

ffil,t,,

L,

"(1,

\,otffSiro

J'ic1\';l::ffi~~it,

--ci,,t,ti,,~Jt),

22-24kg/cm

"'ejri~f;tlt--C<tt~i,,.

){, .:t

©fl!!©l-1v?tt.fl©t.tlr'~"C'©1'~l-

..

-*V,

xr-,v1-~1::.~1,,

"C'

tJ:

1±1*7.>

~·t~-':><•~t-t•t--c <

~i;\,

'·

From the Library of Superior Sewing Machine & Supply LLC

Loading...

Loading...