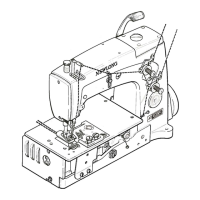

What to do if Newlong Industrial Equipment leaks oil from ?C?

- PPamela GrahamJul 28, 2025

If your Newlong Industrial Equipment is leaking oil from point ?C, the cause might be a loose plug. Try tightening the plug. If the leak persists, replace the lubricator.