5.ADJUSTMENTS

Important!

When adjusting the machine or replacing parts, always

disconnecttheElectricCordfromthepowersource.

This is important in view of safety to the operator and

adjuster.

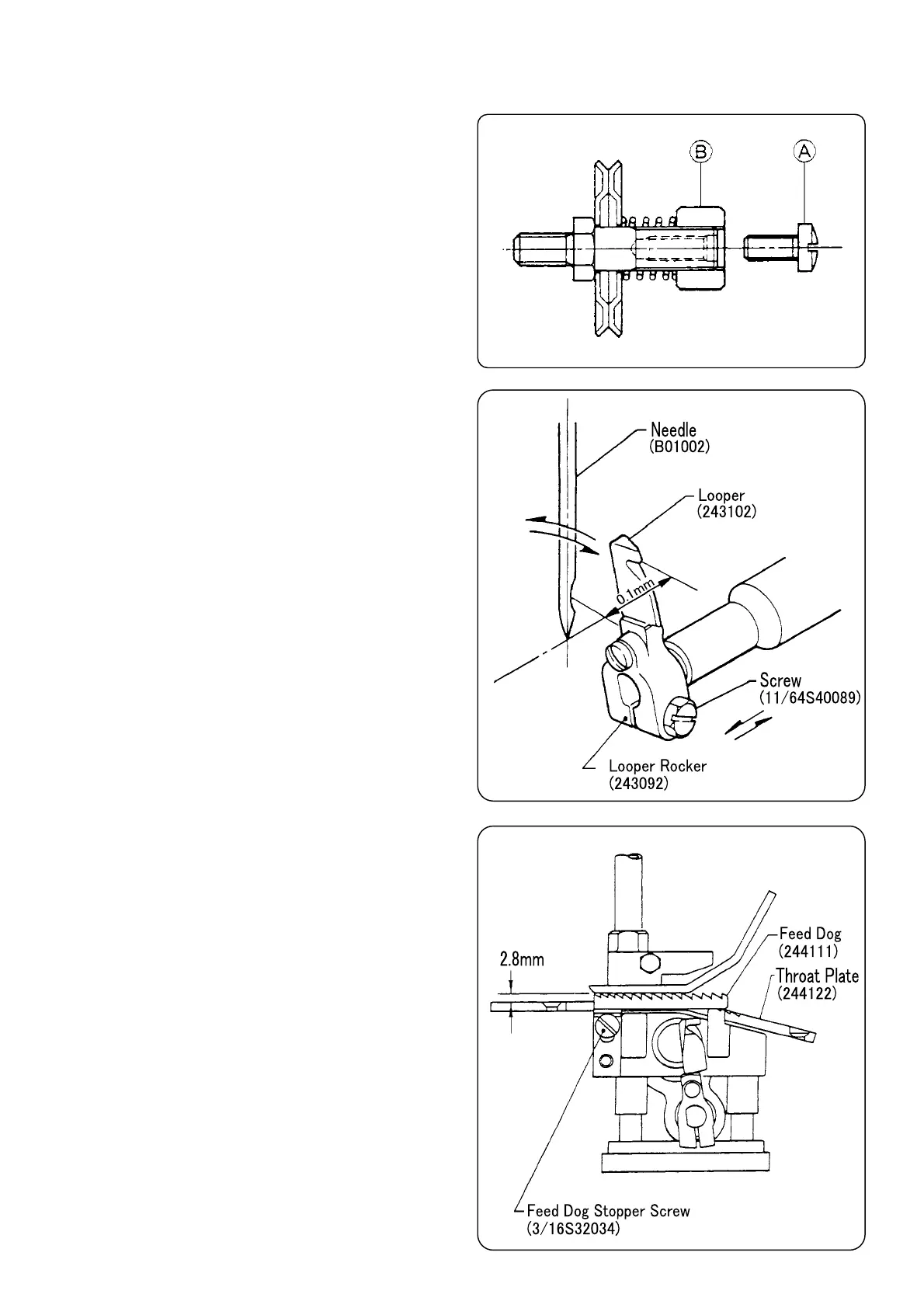

1.ThreadTension(Fig.10)

Thethreadtensionspringispresetatthefactorytosew

PPwovenclothbags.Ifsomeadjustmentisneeded,first

loosen screw

○

A (9/64S40054) and adjust the thread

tension nut

○

B (245092) as per Fig.10. When the

adjustmentisfinished,retightenscrewtolockthethread

tensionnut.

Ifthisisnotdone,thestitchwillnotremainuniform.

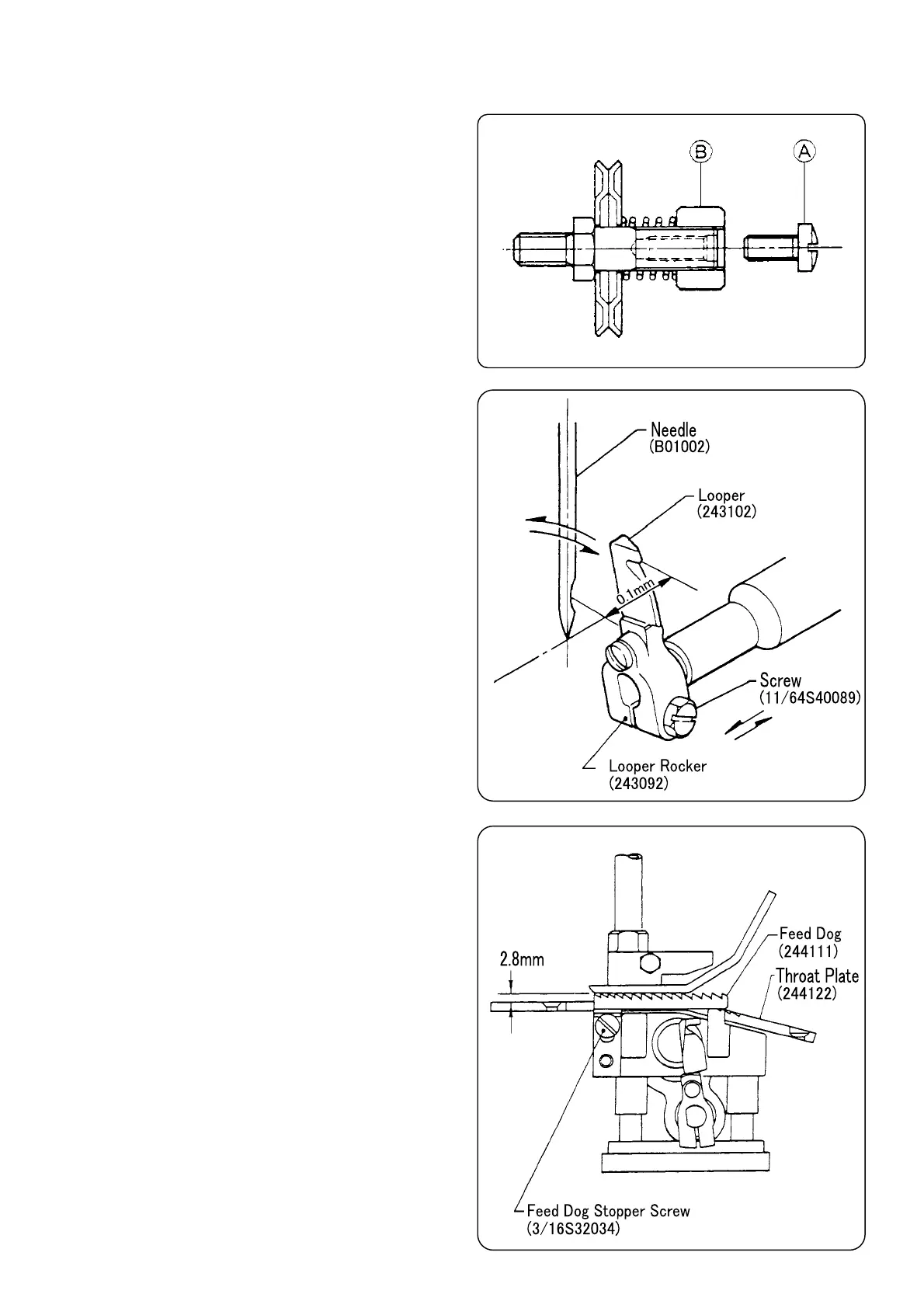

2.PositionofNeedleandLooper(Fig.11)

Looper must pass the concave part of Needle with

clearanceof0.1mmasshowninFig.11.Adjustmentofthe

clearancecanbedoneafterlooseningthescrewofLooper

Rocker.

3.PositionofFeedDog(Fig.12)

Wheninstallinganewfeeddogensurethatitispositioned

correctlyontothefeeddogcarrierblockandlightly

tightenthefixingscrew.Checkthatthefeeddogteethare

2.8mmabovethethroatplatewhenthefeeddogisinthe

highestpositionbeforefinaltighteningofthefixingscrew.

4.PressureofPresserFoot

When to adjust the pressure of Presser Foot, take out

NeedleBarGuardandloosenScrewofPresserBar

Connection. Move up Presser Bar to increase the

pressure and down to decrease. After the adjustment,

tightentheScrewfirmly.

5.PressureFootLifter

ThePresserFootLifterisusedtoliftthePresserFoot

andpulloutabagfromunderthePresserFootincaseofa

problemsuchasbagorthreadjamming.

6.HowtouseHook(PartNo.241151)

TheHookonthePulleyCoverisusedtoinstallaShoulder

BeltoraHanger.

5

Fig.10

Fig.11

Fig.12

Loading...

Loading...