3.PREPARRATIONFORSTART

1.Oiling(Fig.1)

Oilingisimperativetokeepthemachineingoodoperating

condition.Pouroilinthereservoir(capacity45cc).Tobegin

the flow of oil to the machine, push the button of the

lubricator ten times continuously before starting the

machine. This should dispense enough oil for an average

runningoffourhoursundernormaloperatingconditions.Do

notrunthemachinewithoutoilasitcouldcausesamachine

failureorbreakdown.

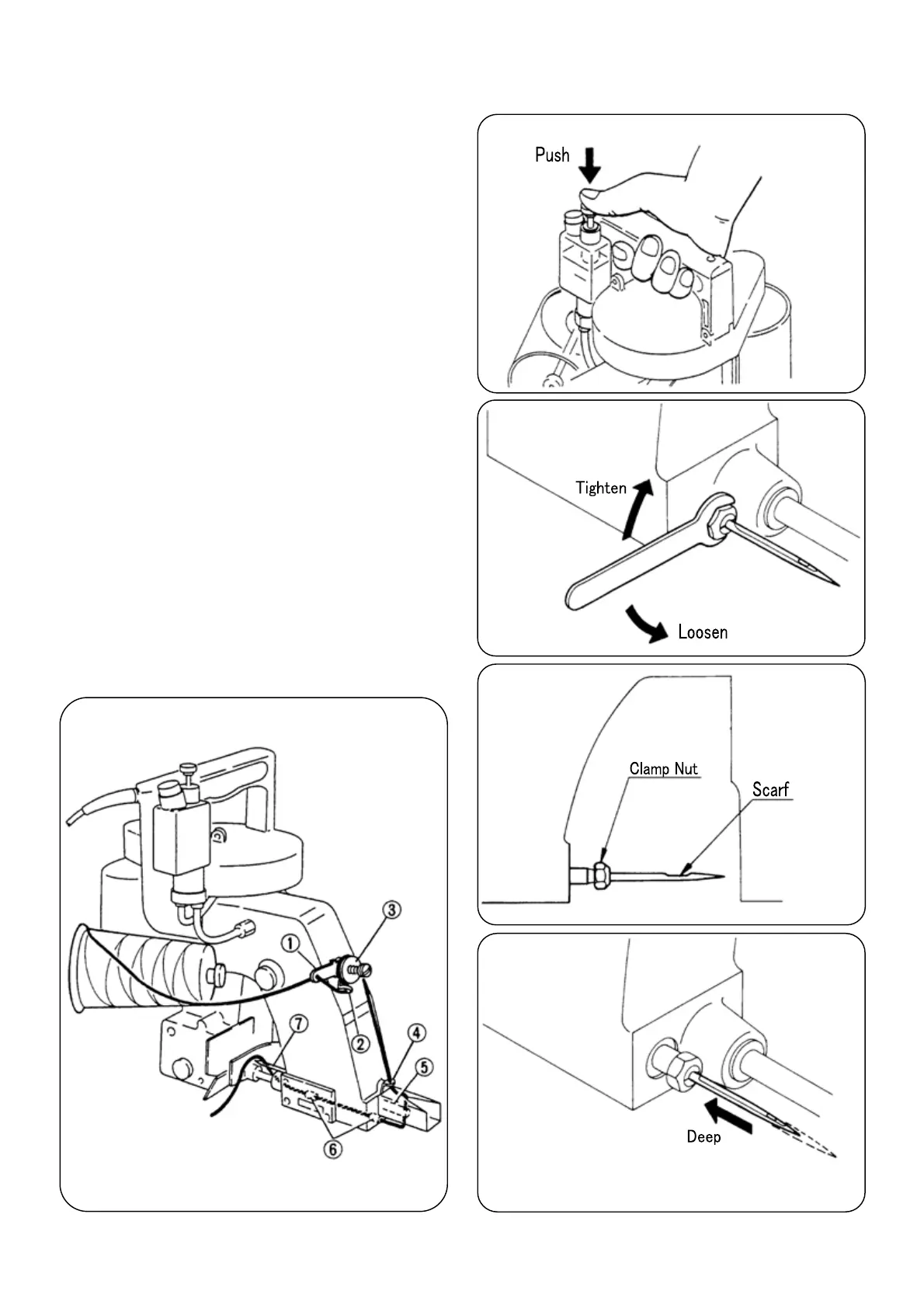

2.NeedleSetting(Fig.2,3,4)

TurnthepulleyuntilNeedleBarreachesitshighestposition.

LoosenNeedleBarClampingNut,andsetNeedleintheBar

asdeepasitwillgo.

BesuretosetaNeedlewithitsconcavepartfacingcorrectly

toward the Looper. Fix Clamping Nut tightly, otherwise

Needlemaycomelooseduringoperationandbreak.

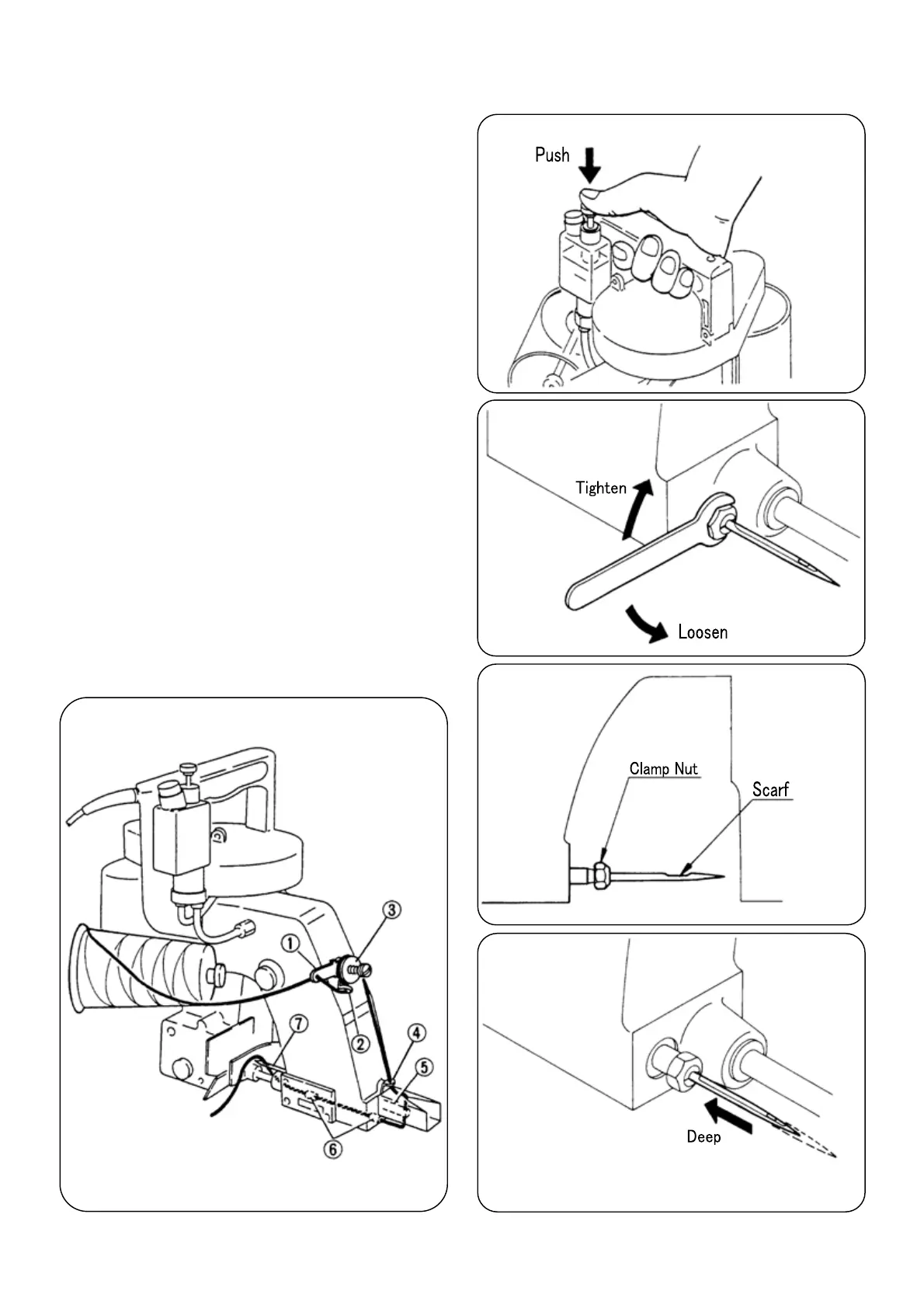

3.Threading(Fig.5)

Themachineisdeliveredbeingthreadedtoshowyouproper

threading of the machine, which is shown in Fig.5, for

identification.Followtheguidenumbers1to7ofFig.5.

①,②ThreadEyelet ⑤NeedleBar

③TensionDisc ⑥ThreadEyelet

④ThreadEyelet ⑦Needle

3

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Loading...

Loading...