6.REPLACINGPARTS

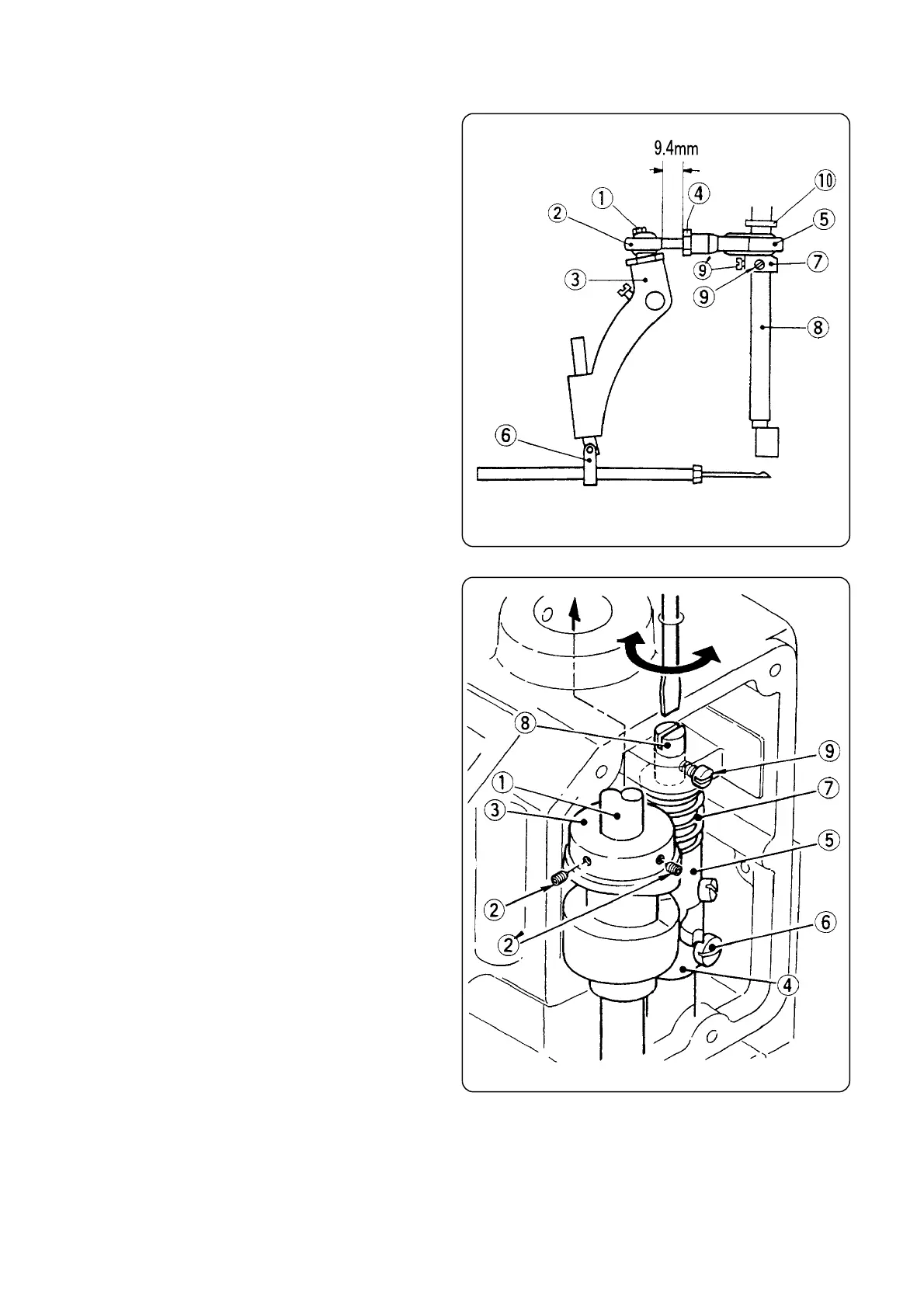

ForreplacementoradjustmentofBallRod,refertoFig.13.

TakeoutScrew①anddisconnectRodEnd② from

NeedleBarLever ③.AfterlooseningtheNut ④,adjustthe

clearancebetweenConnectingRod ⑤ andRodEnd ②,so

thatNeedleBarmovesinthecenteroftheclearance

betweentheupperandlowerPresserBarBushings.(Needle

Barstrokeis37mm).

TofixEccentricCam⑦onMainShaft⑧,tightenthe

Screw⑨and⑨ʼonMainShaft⑧(EccentricCam⑦

shouldcontactSpacer ⑩ slightly.).

ThepositionofNeedleisadjustedsothatthedistance

between the point of Needle (at its highest position) and

ThroatPlateis13mm,afterlooseningscrewonNeedleBar

ConnectionAssembly ⑥ inFig.13.

①Screw11/64S40084

②RodEnd6A04001

③NeedleBarLever242051A

④Nut1N8

⑤ConnectingRodAssembly242011A

⑥NeedleBarConnectionAssembly242101A

⑦Eccentric Cam (part of Connecting Rod Assembly)

242011

⑧MainShaft241102

⑨⑨ʼScrew11/64S40001

⑩Spacer241161

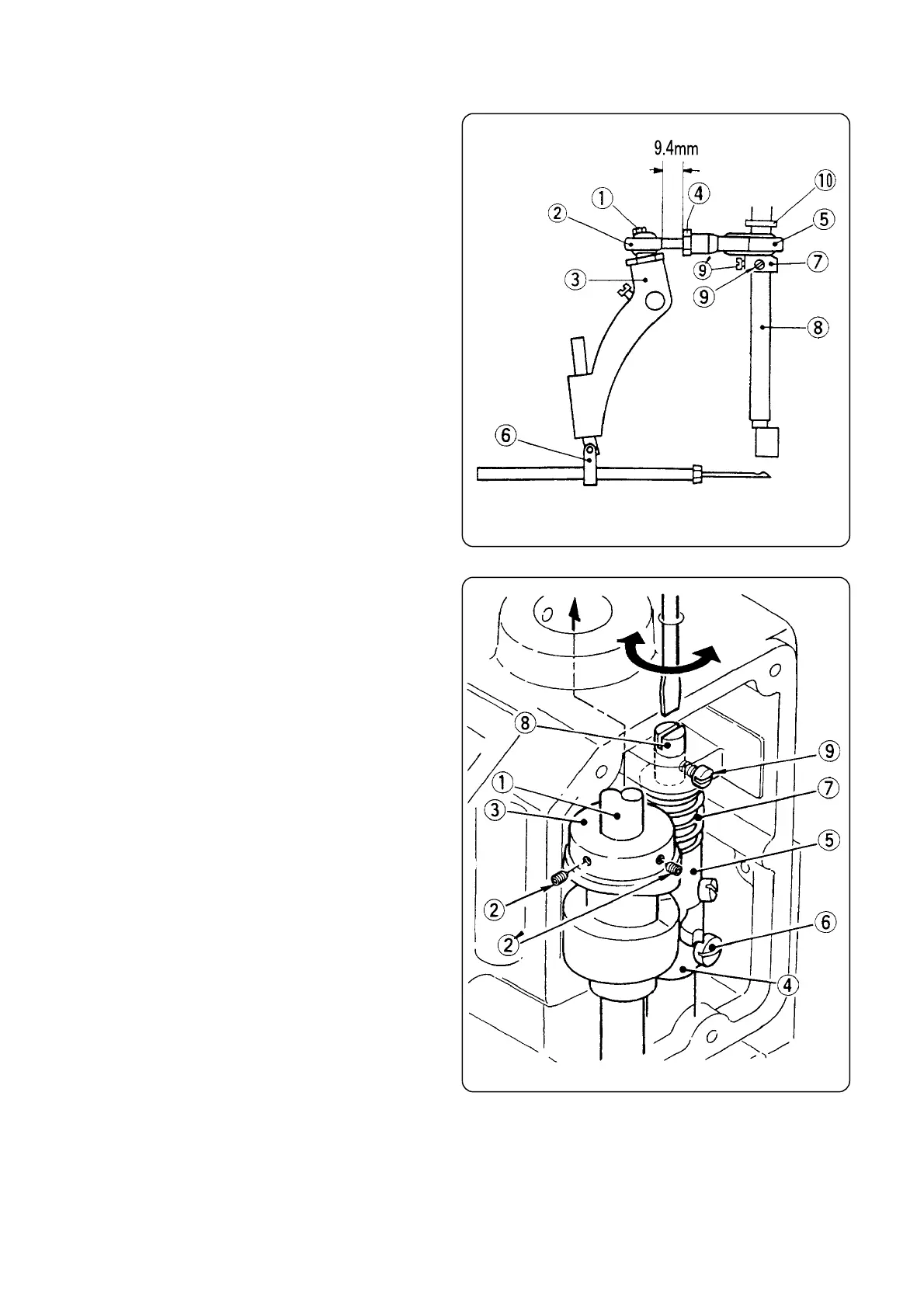

Adjust Looper Drive Cam ③ When necessary as

follows:(RefertoFig.14.).

a)Apply the Screws ② and ②ʼ on the taper of Main

Shaft ①.

b)AdjustArm(B) ④,sothatLooperDriveCam ③ and

Arm (A) ⑤ move smoothly. After adjusting, fix the

Screw ⑥ tightly.

c)TheclearancebetweenLooperDriveCam ③andArm

⑤ iseffectedbySpring ⑦.LoosenScrew ⑨ andturn

SpringSupporter⑧toadjustthepressureofSpring

⑦. After adjusting, tighten the Screw ⑨ to fasten

SpringSupporter ⑧.

①MainShaft241102

②②ʼScrew15/64S28524

③LooperDriveCam243012

④LooperRockerShaftArm(B)243081

⑤LooperRockerShaftArm(A)243071

⑥ScrewforLooperRockerShaftArm(B)11/64S40009

⑦Spring243131

⑧SpringSupporter243121

⑨ScrewforSpringSupporterBlock11/64S40003

6

Fig.13

Fig.14

Loading...

Loading...