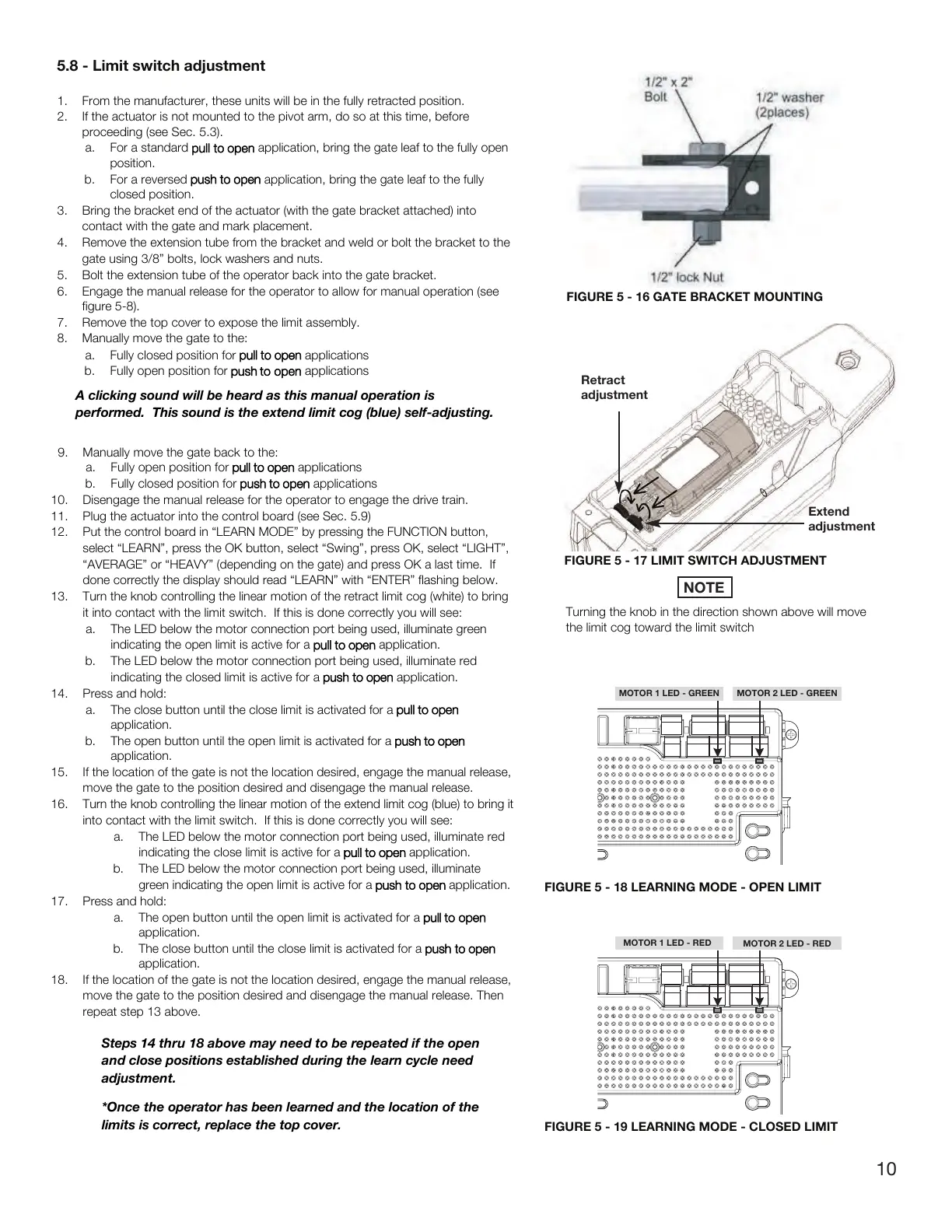

MOTOR 1 LED - GREEN MOTOR 2 LED - GREEN

MOTOR 2 LED - RED

5.8 - Limit switch adjustment

FIGURE 5 - 19 LEARNING MODE - CLOSED LIMIT

10

MOTOR 1 LED - RED

FIGURE 5 - 18 LEARNING MODE - OPEN LIMIT

FIGURE 5 - 16 GATE BRACKET MOUNTING

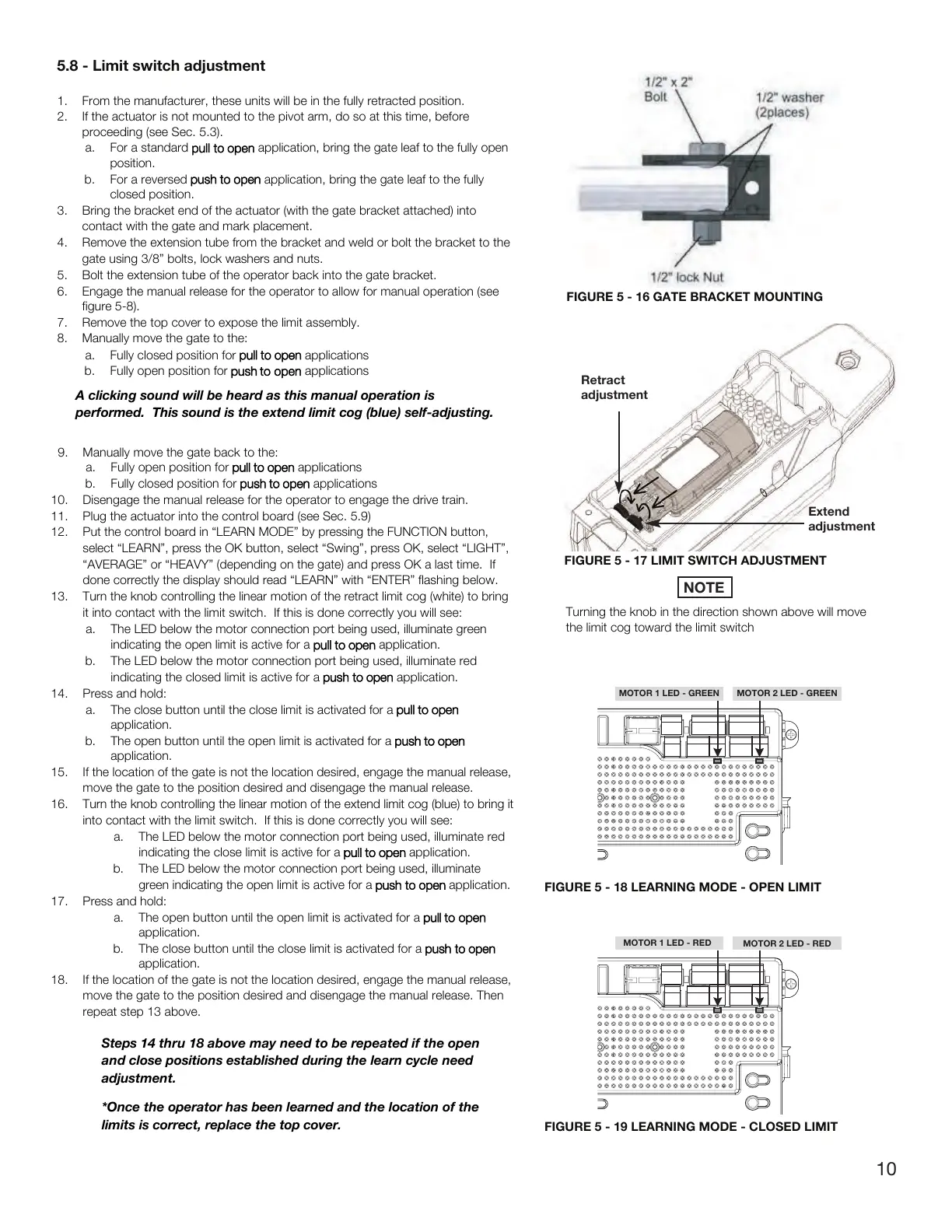

FIGURE 5 - 17 LIMIT SWITCH ADJUSTMENT

Retract

adjustment

Extend

adjustment

Turning the knob in the direction shown above will move

the limit cog toward the limit switch

NOTE

1. From the manufacturer, these

units will be in the fully retracted position.

2. If the actuator is not mounted to the pivot arm, do so at this time, before

proceeding (see Sec. 5.3).

a. For a standard

pull to open application, bring the gate leaf to the fully open

position.

b. For

a reversed

push to open application, bring the gate leaf to the fully

closed position.

3. Bring

the bracket end of the actuator (with the gate bracket attached) into

contact with the gate and mark placement.

4. Remove the extension tube from the bracket and weld or bolt the bracket to the

gate using 3/8” bolts

, lock washers and nuts.

5. B

olt

the extension tube of the operator back into the gate bracket.

6. Engage the manual release for the operator to allow for manual operation (see

figure 5-8).

7. Remove the top

cover to expose the limit

assembly.

8. Manually move the gate to the:

a. Fully closed position for

pull to open applications

b. Fully

open position for

push

to open applications

A clicking sound will be heard as this manual operation is

performed. This sound is the extend limit cog (blue) self-adjusting.

9. Manually move the gate back to the:

a. Fully open position for

pull to open applications

b. Fully

closed position for

push to open applications

10. Disengage the manual

release for the operator to engage the drive train.

11. Plug the actuator into the control board (see Sec. 5.9)

12. Put the control board in “LEARN MODE” by pressing the FUNCTION b

utton,

select “LEARN”, press the

OK button, select “Swing”, press OK, select “LIGHT”,

“AVERAGE” or “HEAVY” (depending

on

the gate) and press OK a last time.

If

done correctly the display should read “LEARN” with “ENTER” flashing

below.

13. Turn the knob controlling the linear motion of the

retract limit cog (white) to bring

it into contact with the

limit switch. If this is done correctly you will see:

a. The LED below the motor connection port being used, illuminate green

indicating the open limit

is active for a

pull to open application.

b. The LED

below the motor connection port being used, illuminate red

indicating the closed limit is active for a push to

o

pen application.

14. Press and hold:

a. The

close button until the close limit is activated for a

pull to open

application.

b. The

open button until the open limit is activated for a

push to open

application.

15. If t

he location of the gate is not the location desired, engage the manual release,

move the gate to the position

desired and disengage the manual release.

16. Turn the knob controlling the linear motion of

the extend limit cog (blue) to bring it

into contact with the

limit switch. If this is done correctly you will see:

a. The LED below the motor connection port being used, illuminate red

indicating the close limit is active for a

pull to open application.

b. The

LED below the motor connection port being used, illuminate

green indicating the open limit

is active for a push to o

pen application.

17. Press and hold:

a. The open

button until the open limit is activated for a

pull to open

application.

b. The close button

until the close limit is activated for a push to o

pen

application.

18. If

the location of the gate is not the location desired, engage the manual release,

move the gate to the position

desired and disengage the manual release. Then

repeat step 13 above.

Steps 14 thru 18 above may need to be repeated if the open

and

close positions established during the learn cycle need

adjustment.

*Once the operator has been learned and the location of the

limits is correct, replace the top cover

.

Loading...

Loading...