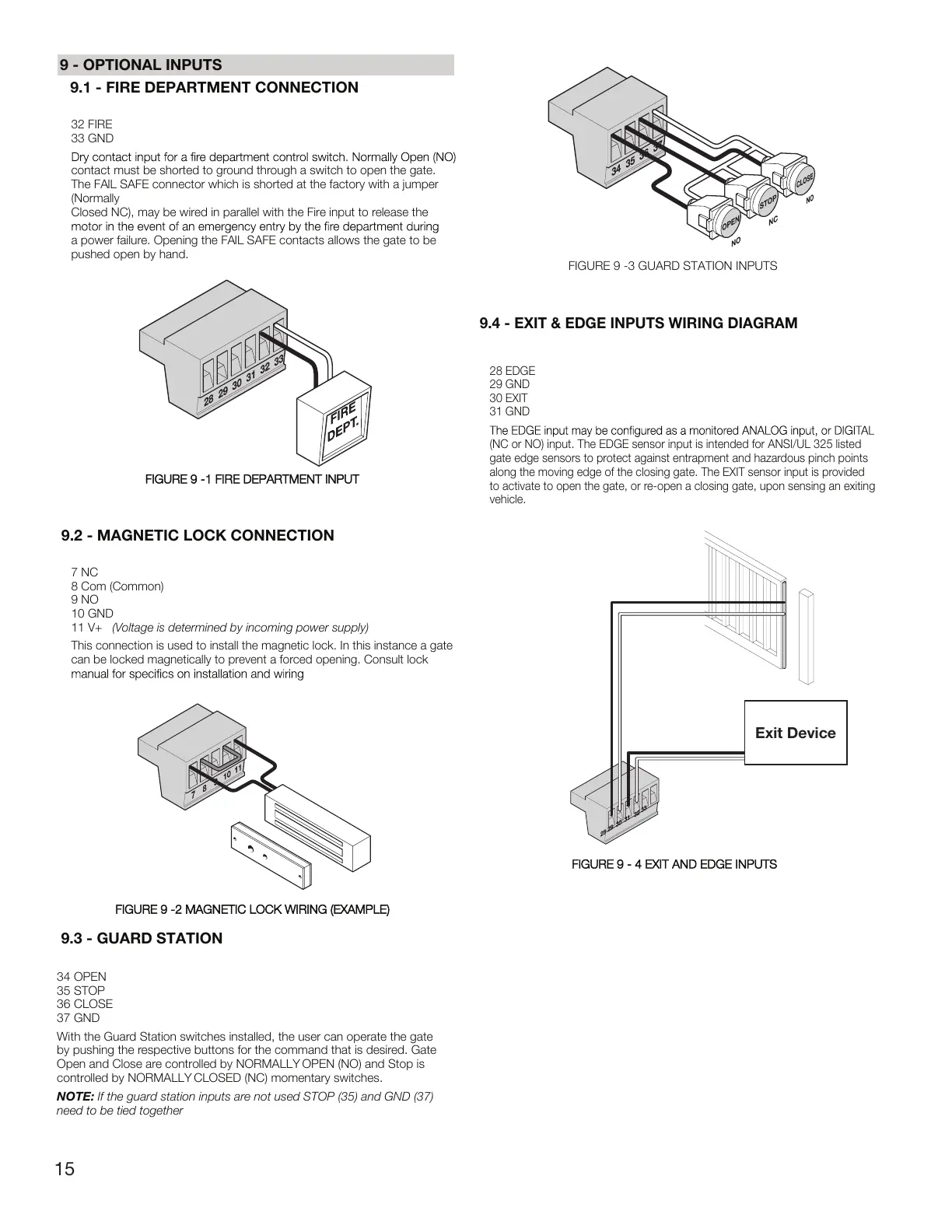

32 FIRE

33 GND

contact must be shorted to ground through a switch to open the gate.

The FAIL SAFE connector which is shorted at the factory with a jumper

(Normally

Closed NC), may be wired in parallel with the Fire input to release the

a power failure. Opening the FAIL SAFE contacts allows the gate to be

pushed open by hand.

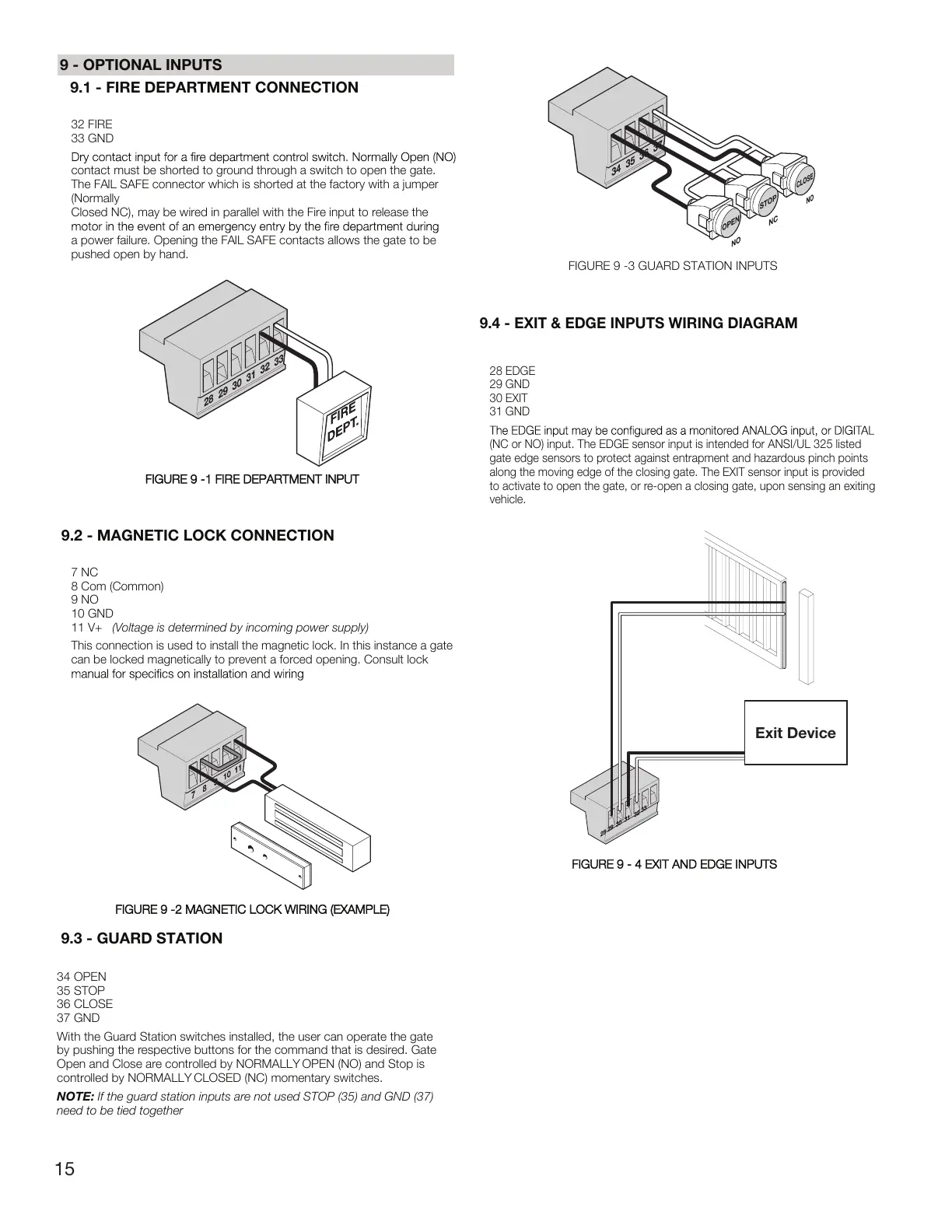

9.4 - EXIT & EDGE INPUTS WIRING DIAGRAM

28 EDGE

29 GND

30 EXIT

31 GND

(NC or NO) input. The EDGE sensor input is intended for ANSI/UL 325 listed

gate edge sensors to protect against entrapment and hazardous pinch points

along the moving edge of the closing gate. The EXIT sensor input is provided

to activate to open the gate, or re-open a closing gate, upon sensing an exiting

vehicle.

9.2 - MAGNETIC LOCK CONNECTION

7 NC

8 Com (Common)

9 NO

10 GND

11 V+ (Voltage is determined by incoming power supply)

This connection is used to install the magnetic lock. In this instance a gate

can be locked magnetically to prevent a forced opening. Consult lock

34 OPEN

35 STOP

36 CLOSE

37 GND

Wi

th the Guard Station switches installed, the user can operate the gate

espective buttons for the command that is desired. Gate

e controlled by NORMALLY OPEN (NO) and Stop is

rolled by NORMALLY CLOSED (NC) momentary switches.

If the guard station inputs are not used

Exit Device

9.1 - FIRE DEPARTMENT CONNECTION

FIGURE 9 -1 FIRE DEPARTMENT INPUT

FIGURE

9 -2 MAGNETIC LOCK WIRING (EXAMPLE)

9.3 - GUARD STATION

FIGURE 9 -3 GUARD STATION INPUTS

FIGURE 9 - 4 EXIT AND EDGE INPUTS

15

Loading...

Loading...