ENGLISH – 19

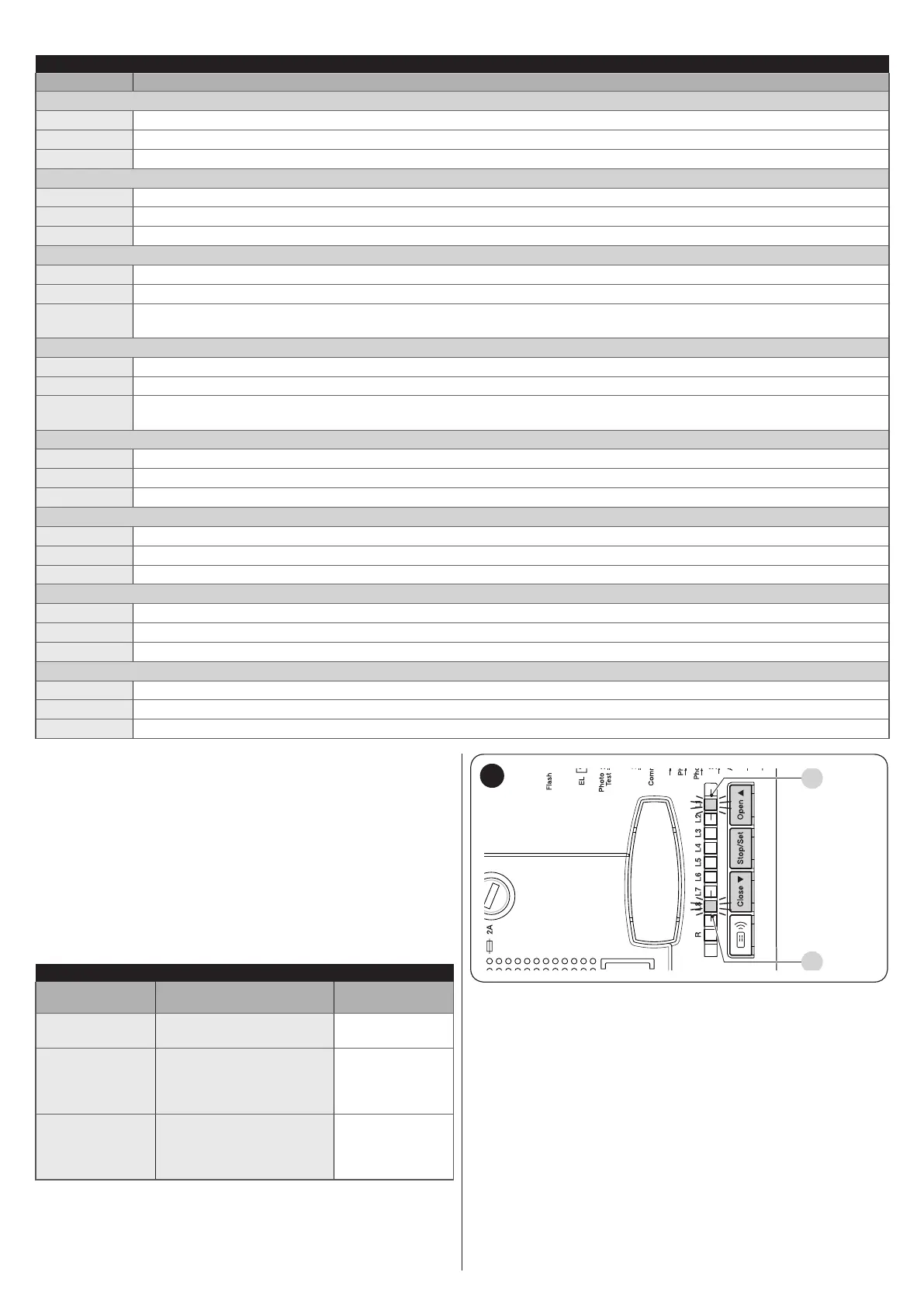

Table 12

SIGNALS OF THE LED ON THE CONTROL UNIT BUTTONS

Status Meaning

L1 LED

OFF

During normal operation, it signals that the “Automatic closing” mode is not active

On

During normal operation, it signals that the “Automatic closing” mode is active

Flashes

Function programming in progress

L2 LED

OFF

During normal operation, it signals that the “Close after photo” mode is not active

On

During normal operation, it signals that the “Close after photo” mode is active

Flashes

Function programming in progress

L3 LED

OFF

During normal operation, it signals that the “Always Close” mode is not active

On

During normal operation, it signals that the “Always Close” mode is active

Flashes

Function programming in progress. If it ashes together with LED L4, the position recognition phase must be carried out

(see the “Automatic limit switch search and “STOP” input acquisition” paragraph)

LED L4

OFF

During normal operation, it signals that the “Stand-by” mode is active

On

During normal operation, it signals that the “Phototest” mode is active

Flashes

Function programming in progress. If it ashes together with LED L3, the position recognition phase must be carried out

(see the “Automatic limit switch search and “STOP” input acquisition” paragraph)

LED L5

OFF

During normal operation, it signals the OGI output as OGI (open gate indicator)

On

During normal operation, it signals the OGI output as ELS (electric lock)

Flashes

Function programming in progress

LED L6

OFF

During normal operation it signals that the “Pre-ashing” mode is not active

On

During normal operation it signals that the “Pre-ashing” mode is active

Flashes

Function programming in progress

LED L7

OFF

During normal operation, it signals that the “Condominium” mode is not active

On

During normal operation, it signals that the “Condominium” mode is active

Flashes

Function programming in progress

LED L8

OFF

During normal operation, it signals that the “Light gates” mode is active

On

During normal operation, it signals that the “Heavy gates” mode is active

Flashes

Function programming in progress

7.3 MAINTENANCE NOTIFICATION

The control unit allows for notifying the user when to perform

maintenance on the automation. The signal is emitted once the

number of manoeuvres completed equals the value set for the

“Maintenance warning” adjustable parameter (see the “Table 8”

paragraph).

The maintenance request signal is emitted through the FLASH

warning light.

The FLASH warning light and the maintenance indicator emit the

signals indicated in “Table 13” based on the number of manoeu-

vres completed with respect to the set limit.

Table 13

MAINTENANCE SIGNALS

Number of ma-

noeuvres

Signal on “Flash”

Signal on mainte-

nance indicator

Below 80% of

the limit

Normal (0.5 s on, 0.5 s

off)

On for 2 s at the

start of opening

Between 81%

and 100% of the

limit

At the start of the

manoeuvre, it remains

lit for 2 s then continues

normally

Flashes

throughout the

manoeuvre

Over 100% of

the limit

At the start and end of

the manoeuvre, remains

lit for 2 s then continues

normally

Flashes always

7.4 ANOMALY LOG

The control unit can display any anomalies that have occurred

in the last 8 manoeuvres (for example, the interruption of a ma-

noeuvre due to the intervention of a photocell or sensitive edge).

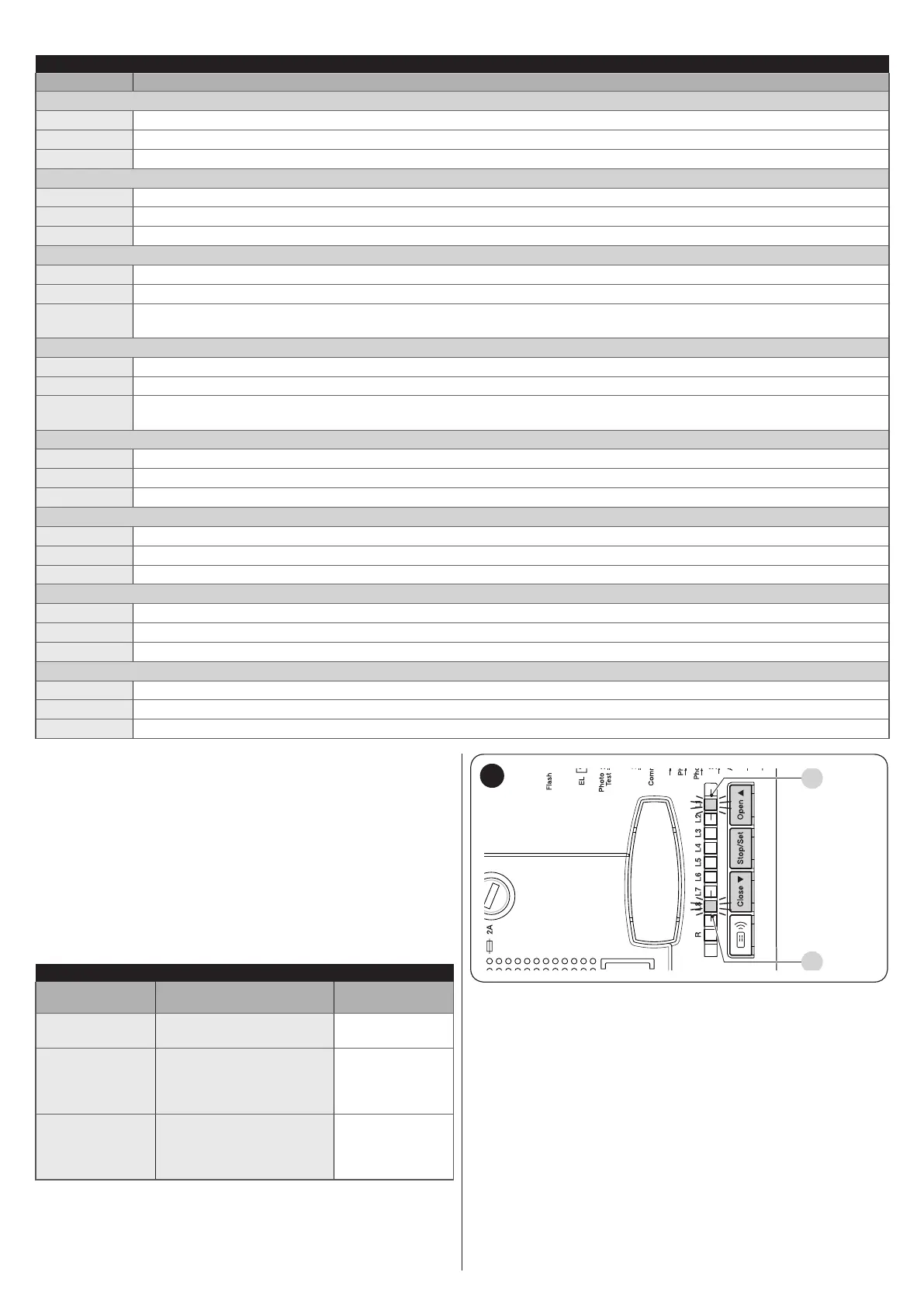

L1

L8

27

To check the list of anomalies:

1. press and hold the [Stop/Set] button for roughly 3 sec-

onds

2. release the [Stop/Set] button when the “L1” LED starts

ashing

3. press and release the [Open

p

] or [Close

q

] button to

shift ashing of the LED to “L8” (“Anomaly list” parameter)

4. keep the [Stop/Set] button pressed down (it must be kept

pressed throughout phases 5 and 6)

5. wait roughly 3 seconds, after which LED “L1” – corre-

sponding to the outcome of the last manoeuvre – will light

up

6. press and hold the [Open

p

] or [Close

q

] button to se-

lect the desired manoeuvre: the corresponding LED will

emit the same number of ashes as those normally emit-

ted by the warning light after an anomaly (see “Table 10”)

7. release the [Stop/Set] button.

Loading...

Loading...