EN

English – 9

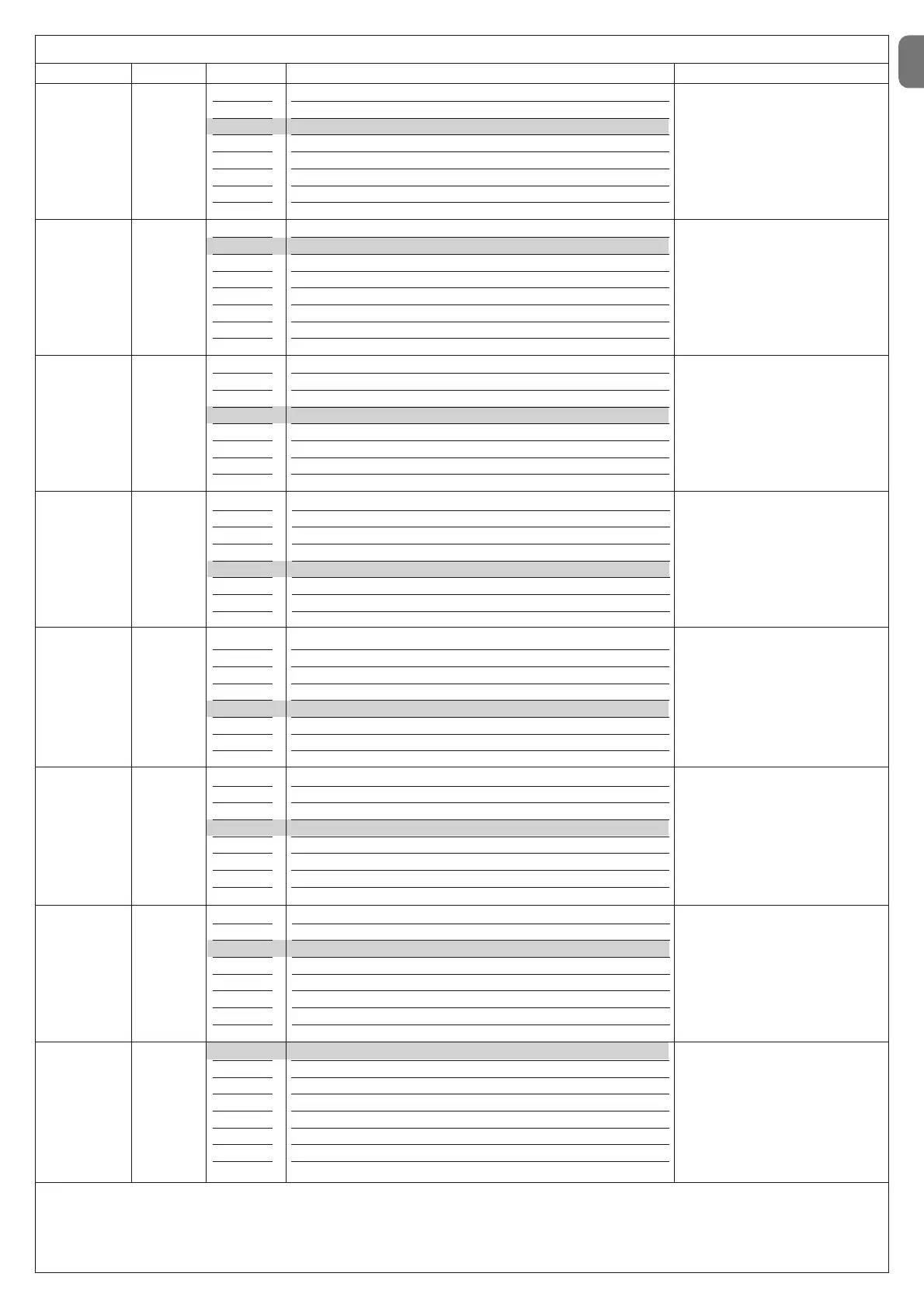

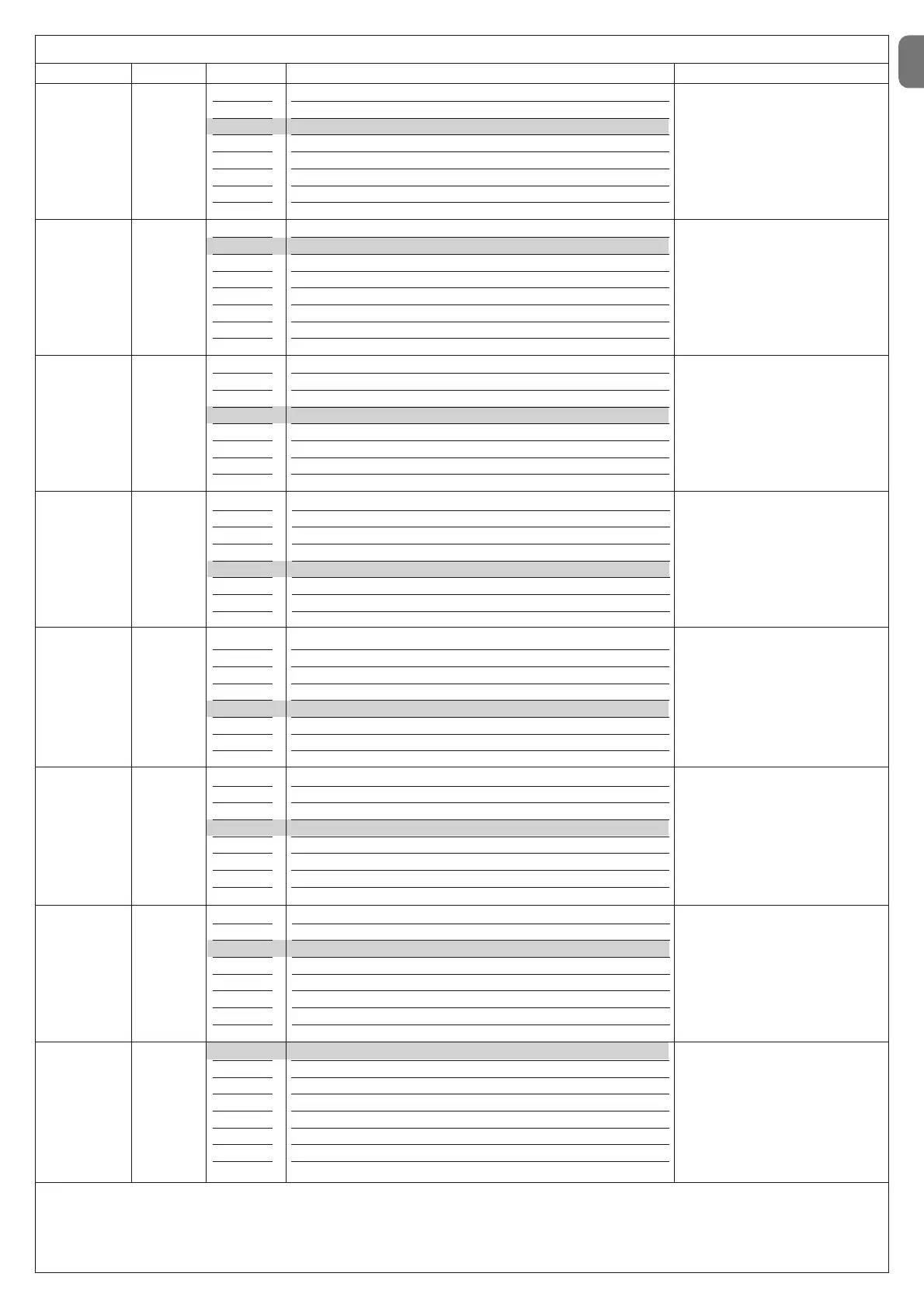

Note – Grey colour represents the factory setting.

WARNINGS:

- Do not set an excessively high value for the “motor force” as this may impair operation of the safety system or damage the pole;

- If the “Motor force control” is used in support of the system for impact force reduction, after each adjustment the force measurement procedure must be performed, as envisaged

by standard EN 12445.

- Wear and atmospheric conditions influence movement of the pole; motor force settings should be checked periodically.

L8 L1

L2

L3

L4

L5

L6

L7

L8

Manoeuvre 1 result (most recent)

Manoeuvre 2 result

Manoeuvre 3 result

Manoeuvre 4 result

Manoeuvre 5 result

Manoeuvre 6 result

Manoeuvre 7 result

Manoeuvre 8 result

The type of fault that has occurred in

the last 8 manoeuvres can be establi-

shed (see: paragraph 8.2 - malfunction

event log and Table 14).

A detailed log can be stored of all events

on SBAR (and other devices connected

on the network) by connecting the

Oview programmer

List of

faults

TABLE 7 - Second level functions

Input LED Parameter LED (level) Value Description

L1 L1

L2

L3

L4

L5

L6

L7

L8

5 seconds

10 seconds

20 seconds

40 seconds

60 seconds

80 seconds

120 seconds

200 seconds

Sets the pause time, i.e. the time that

passes between the end of an ope-

ning manoeuvre and the start of an

automatic closing manoeuvre

This parameter is only effective if the

“automatic Closure” is active.

Time

Pause

L2 L1

L2

L3

L4

L5

L6

L7

L8

Open – stop – close - stop

Open – stop – close - open

Open – close – open - close

Apartment block (more than 2 sec. generates Stop)

Apartment block 2 (less than 2 sec. generates partial opening).

Step by step 2

Hold-to-run

Opening in semi-automatic mode, closing in dead man mode

Sets the sequence of commands as-

sociated with the input or the radio

control: "Step by step”.

Function

Step by

step

L3 L1

L2

L3

L4

L5

L6

L7

L8

Speed 1 (30% - slow)

Speed 2 (47%)

Speed 3 (65%)

Speed 4 (82%)

Speed 5 (100%) - fast

Open V3, Close V2

Open V4, Close V3

Open V5, Close V4

Sets the motor speed during normal

travel.

Speed

Motor

L4 L1

L2

L3

L4

L5

L6

L7

L8

Pole Open Indicator Function (24 V - 10 W)

Active if pole closed (24 V - 10 W)

Active if pole open(24 V - 10 W)

Flashing light(12 V - 21 W)

Flashing light for pole lights (24 V - 10 W) - always flashes

Electric lock(24 V - 10 W)

Suction cup(24 V - 10 W)

Maintenance indicator (24 V - 10 W)

Selects the type of device connected

to the FLASH output.

Important! – If the programmed set-

ting is modified, check the type of vol-

tage of the new device connected to

the FLASH terminal and ensure that it

corresponds to the type of voltage of

the selected programming level.

Output

FLASH

L5 L1

L2

L3

L4

L5

L6

L7

L8

Force 1 (low)

Force 2

Force 3

Force 4

Force 5

Force 6

Force 7

Force 8 (high)

Adjusts the motor force control sy-

stem to adapt it to the weight of the

pole during the opening manoeuvre

and consequently the sensitivity of

obstacle detection.

Note – The force is acquired auto-

matically during execution of the first

two manoeuvres.

Motor force

on opening

L6 L1

L2

L3

L4

L5

L6

L7

L8

Force 1 (low)

Force 2

Force 3

Force 4

Force 5

Force 6

Force 7

Force 8 (high)

Adjusts the motor force control sy-

stem to adapt it to the weight of the

pole during the closing manoeuvre

and consequently the sensitivity of

obstacle detection.

Note – The force is acquired automa-

tically during execution of the first two

manoeuvres.

Motor force

on closure

L7 L1

L2

L3

L4

L5

L6

L7

L8

2500

5000

10000

15000

20000

30000

40000

50000

When the FLASH output is program-

med as a maintenance indicator: this

sets the maximum number of mano-

euvres to be performed, after which

the signal is sent to notify of the need

for automation maintenance.

Mainte-

nance

warning

Loading...

Loading...