Unidrive M702 / HS72 Control Getting Started Guide 11

Issue Number: 4

Safety information Introduction Control connections Getting started

Basic parameters

(Menu 0)

Running the motor Further information

3.3 Shield connections

The following guidelines should be followed to ensure suppression of radio-frequency

emission and good noise immunity. It is particularly recommended that the guidelines for the

encoder cable be followed closely in order to avoid disturbance to the encoder operation from

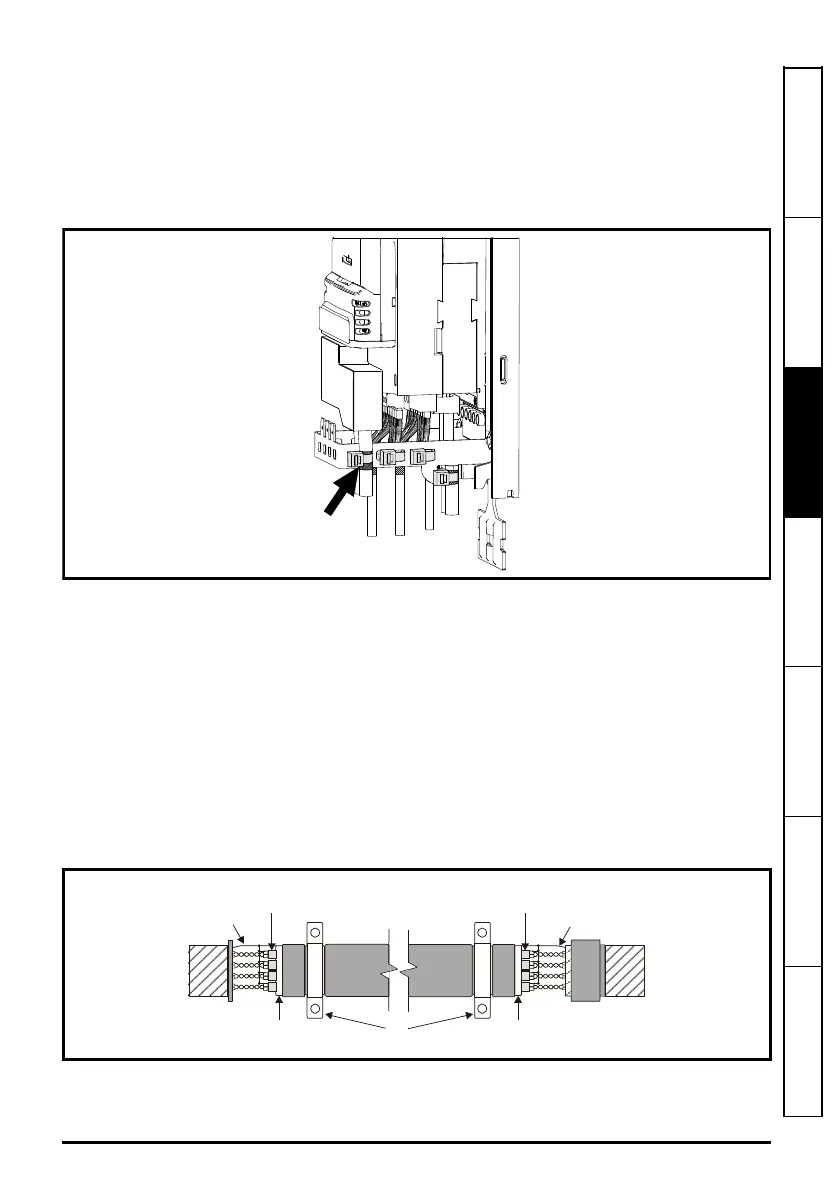

electrical noise. Use the grounding bracket and grounding clamp supplied with the drive to terminate

the shields at the drive.

Figure 3-3 Grounding of signal cable shields using the grounding bracket

Motor cable: Use a motor cable with an overall shield. Connect the shield of the motor cable to the

ground terminal of the motor frame using a link that is as short as possible and not exceeding 50 mm

(2 in) long. A full 360° termination of the shield to the terminal housing of the motor is beneficial.

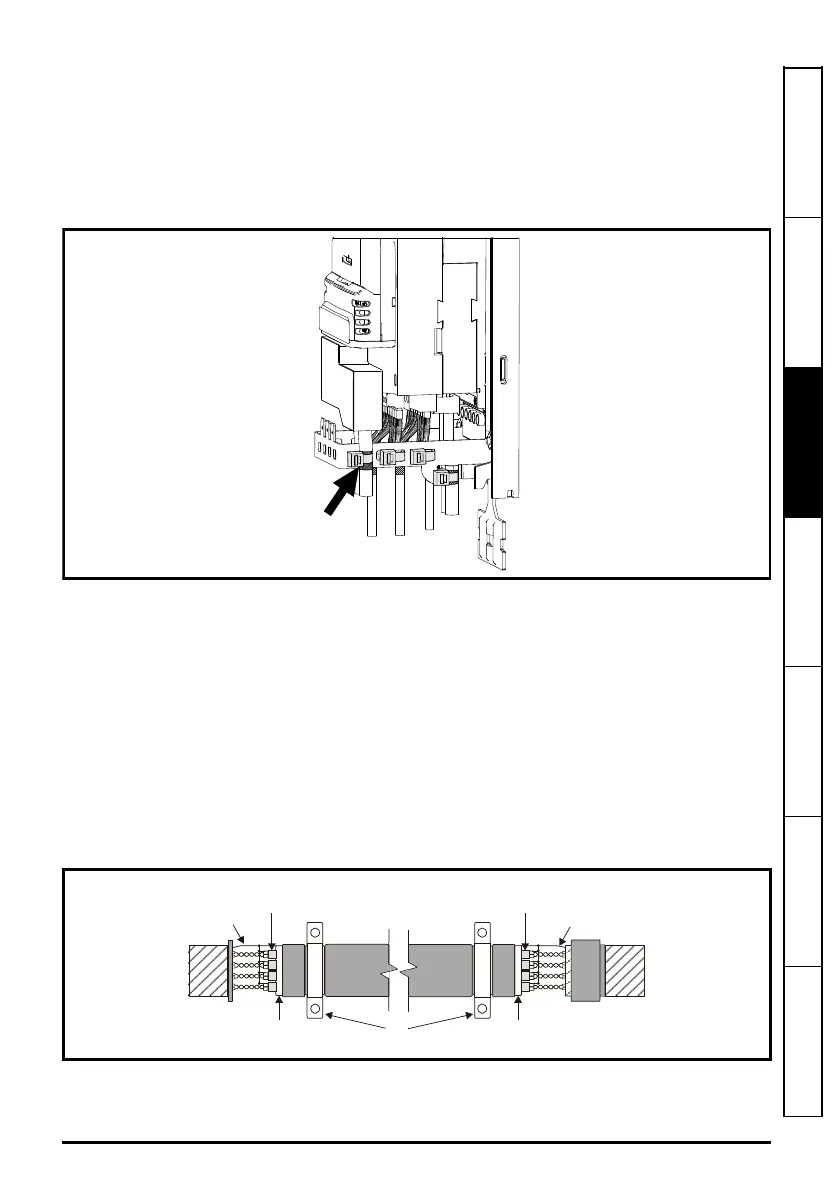

Encoder cable: For best shielding use cable with an overall shield and individual shields on twisted

pairs, connect the cable as illustrated in Figure 3-4. Clamp the overall shield to grounded metallic

surfaces at both the encoder and the drive.

Brake resistor cable: The optional braking resistor should also be wired with shielded cable. If

unshielded wire is required refer to the Control User Guide for guidance.

Control cables: If the control wiring is to leave the enclosure, it must be shielded and the shield(s)

clamped to the drive using the grounding bracket. Remove the outer insulating cover of the cable to

ensure the shield(s) make contact with the bracket, but keep the shield(s) intact until as close as

possible to the terminals.

Figure 3-4 Feedback cable shield connections

Cable

Cable

shield

Twisted

pair

shield

Cable

shield

Twisted

pair

shield

Connection

at motor

Connection

at drive

Ground clamp

on shield

connection

to 0V

Shield

connection

to 0V

Loading...

Loading...