ELECTRICAL SYSTEM

FORM NO. 56043088 / Advenger

™

/ BR 600S, 650S, 700S, 800S - 51

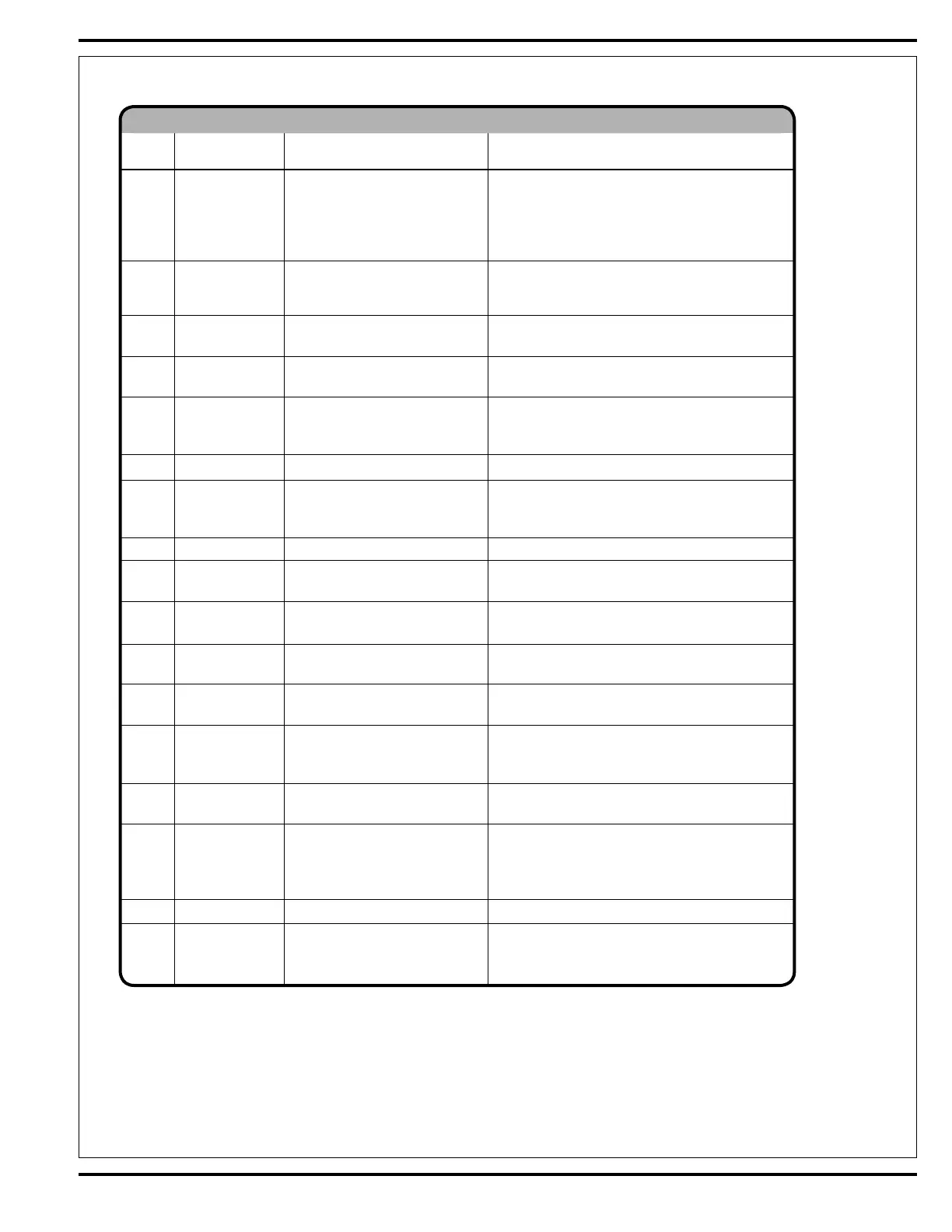

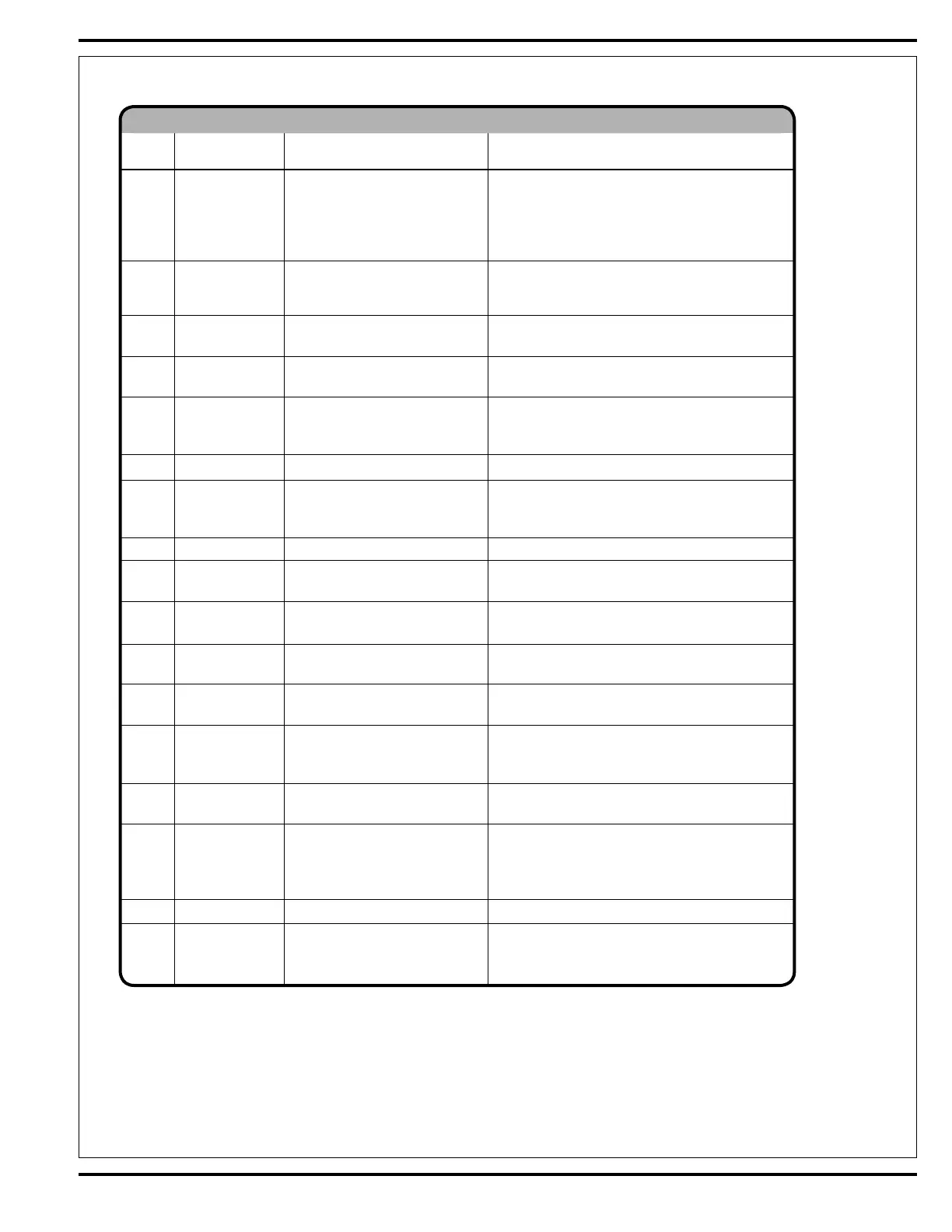

STATUS LED FAULT CODES (TABLE 1)

LED STATUS LIGHT EXPLANATION POSSIBLE CAUSE

CODE DISPLAY

1,1 O O over-/under-temperature cutback 1. Temperature >97°C (206°F) or < -25°C (-13°F).

2. Excessive load on vehicle.

3. Operation in extreme environments.

4. Electromagnetic, foot or parking brake not

releasing properly.

1,2 O OO throttle fault 1. Throttle input wire open or shorted.

2. Throttle pot defective.

3. Wrong throttle type selected.

1,3 O OOO speed limit pot fault 1. Speed limit pot wire(s) broken or shorted.

2. Broken speed limit pot.

1,4 O OOOO battery voltage too low 1. Battery voltage <17 volts.

2. Bad connection at battery or controller.

1,5 O OOOOO battery voltage too high 1. Battery voltage >36 volts.

2. Vehicle operating with charger attached.

3. Intermittent battery connection.

2,1 OO O main contactor driver Off fault 1. Main contactor driver failed open.

2,3 OO OOO main contactor fault 1. Main contactor welded or stuck open.

2. Main contactor driver fault.

3. Brake coil resistance too high.

2,4 OO OOOO main contactor driver On fault 1. Main contactor driver failed closed.

3,1 OOO O HPD fault present for >10 sec. 1. Misadjusted throttle.

2. Broken throttle pot or throttle mechanism.

3,2 OOO OO brake On fault 1. Electromagnetic brake driver shorted.

2. Electromagnetic brake coil open.

3,3 OOO OOO precharge fault 1. Controller failure.

2. Low battery voltage.

3,4 OOO OOOO brake Off fault 1. Electromagnetic brake driver open.

2. Electromagnetic brake coil shorted.

3,5 OOO OOOOO HPD (High Pedal Disable) fault 1. Improper sequence of throttle and KSI*,

push, or inhibit inputs.

2. Misadjusted throttle pot

4,1 OOOO O current sense fault 1. Short in motor or in motor wiring.

2. Controller failure.

4,2 OOOO OO motor voltage fault (hardware 1. Motor voltage does not correspond to

failsafe) throttle request.

2. Short in motor or in motor wiring.

3. Controller failure.

4,3 OOOO OOO EEPROM fault 1. EEPROM failure or fault.

4,4 OOOO OOOO power section fault 1. EEPROM failure or fault.

2. Short in motor or in motor wiring.

3. Controller failure.

*NOTE: A KSI (key switch input) system problem is a specifi c HPD (high pedal disable) type operational fault, caused by the operator activating

the Fwd/Rev drive pedal before turning on the main key switch or activating the throttle before sitting on the seat. This can be cleared by

returning the operator’s drive pedal to neutral and cycling the key switch OFF and ON.

Loading...

Loading...