CONFIDENTIAL

3 (29)

NPE-4 6310/NPL-1 6310i Repair Hints

Customer Care Europe, Middle East & Africa Version 3.0 Approved

SCCE Training Group Date 22.04.2003

© NMP 2003

Checked by:

SCCE Training Group

Approved by:

SCCE

-PCB handling & cleaning

To avoid damages of PCB and/or components through electrostatic discharging, handle the module in

ESD-suitable cases only.

Outside an ESD-bag always wear ESD-bracelets, which must be connected to earth bonding point.

A damage caused by electrostatic discharge does not produce a directly apparent fault, but it will appear (however)

within shortest time.

For cleaning use appropriate materials only. Do not use scratching or rubbing tools.

Usefull tools for cleaning are fluxcleaners such as “Kontakt LR” or “Electrolube FLU” in connection with ionized

compressed air.

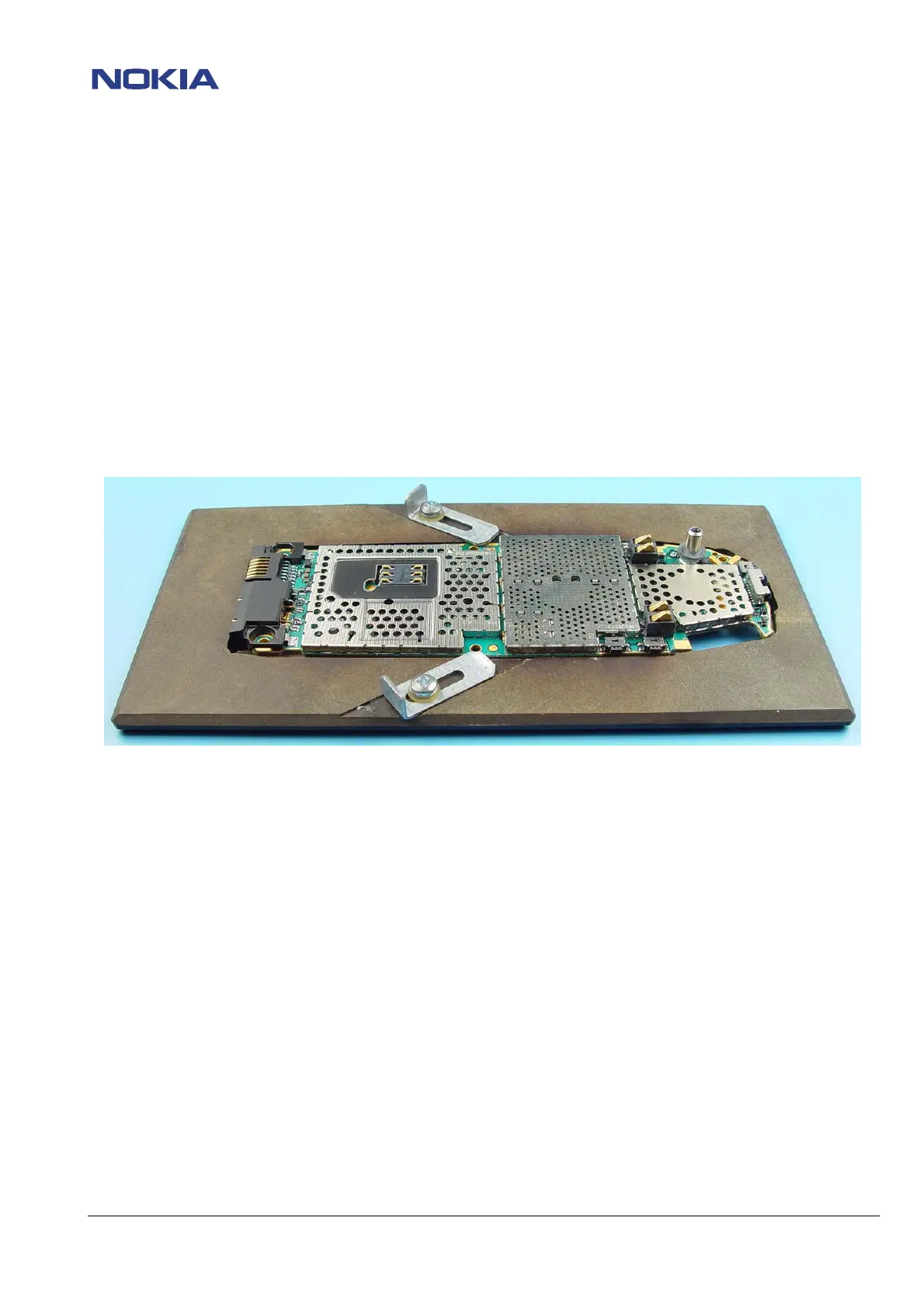

For shield disassembling or any other work on the PCB it is very important to place the PCB into the rework jig JBT-13U

(NMP-code 0770242) to prevent damaging the LEDs – the pads the LEDs are connected with to the PCB are torn off by

applying only little pressure onto the PCB!!!

-Component charactaristics

Some components contain important data as tuning values or security data.

Therefore several steps described are only feasible if you are able to reflash/ realign the phone and/or rewrite

IMEI/SIMlock in certain cases. Please pay attention to separate notes.

-Shieldings, screw torques

To avoid RF-problems it is not allowed to reuse any shielding that once has been removed from shielding frame.

Always use new shieldings after successful repair!

To tighten screws only use a torque screwdriver with a torque adjusted to 17Ncm. Notice tightening order that is

shown in the picture below!

-Realign after repair

Characteristics of replacement may vary.

To prevent additional faults after repair (low standby,, losing network etc.) it is necessary to retune phone values

after repair, but never try to cover up a fault by justing the phone settings!

Loading...

Loading...