Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T

43

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

10. Greasing

10 1Recommendationsaboutgreasing

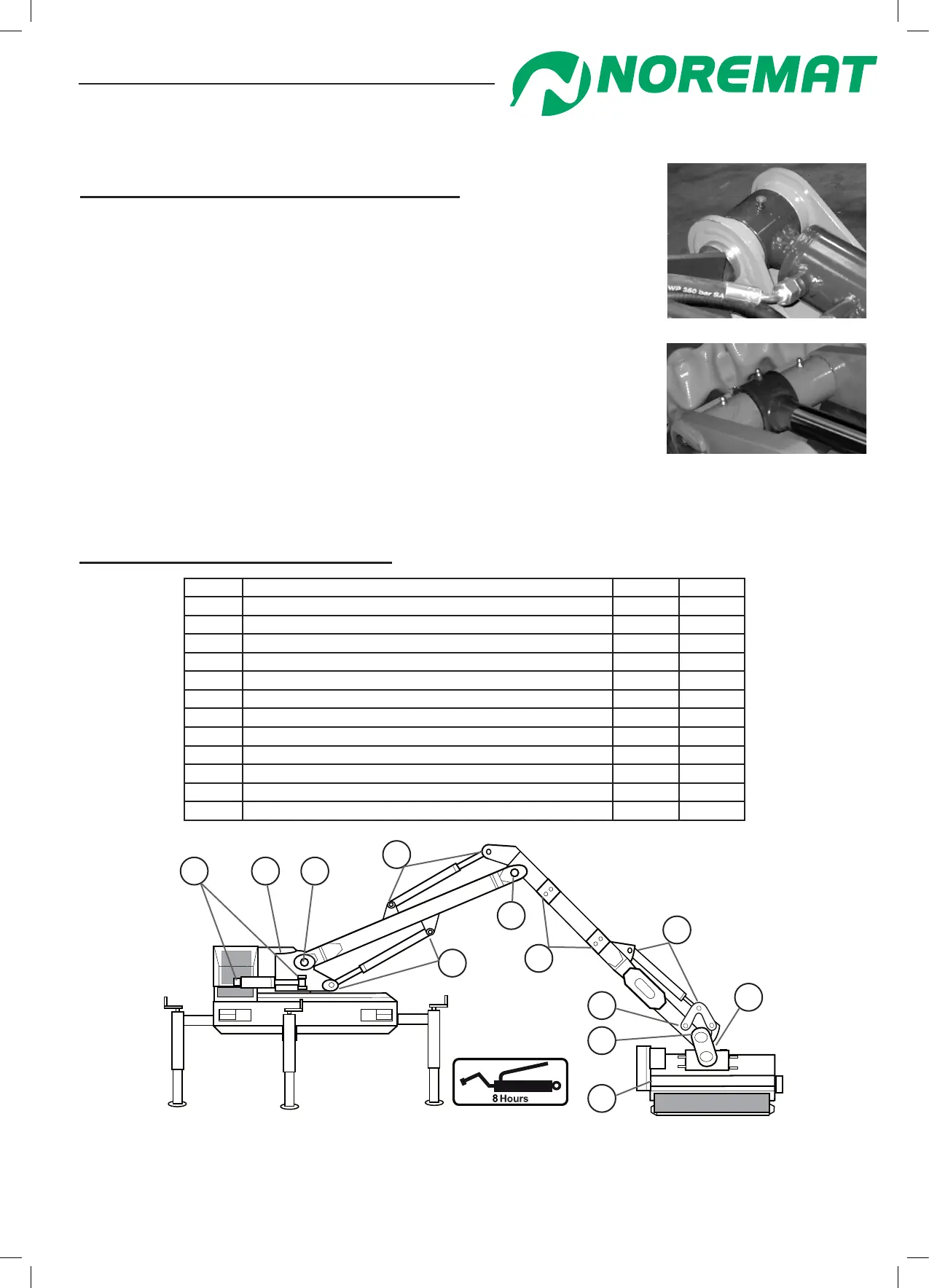

Item GREASING POINT 8 h Qty*

1 Orientation cylinder pins X 8 g

2 Arm pivot / frame pins X 8 g

3 First arm pivot pin X 8 g

4 Second arm pivot pin X 8 g

5 First arm cylinder pins X 8 g

6 Second arm pivot pin X 8 g

7 Telescopic pads (Optima M57T) X 8 g

8 Tool angle cylinder pins X 8 g

9 Tool angle linkage X 8 g

10 Tool pivot pin X 8 g

11 Tool angle link bracket X 8 g

12 Tool, refer to operator’s manual

gure 2.26

gure 2.25

Greasing is an essential part of the maintenance of your machine.

The guarantee of long service life and correct operation depends on strict

observation of the greasing intervals. It is essential to use good quality

grease.

We recommend that you use a Multi-purpose Extreme Pressure grease

of type L-XBDH2 (Conforming to ISO specication standard 6743-9,

alternatively KP2K-25 conforming to DIN 51502 standard).

NOREMAT ref 102475

Before each greasing operation, ensure that the coupler head and the

grease nipple (Figure 2.25 and 2.26) are in good condition and clean.

If your machine is equipped with ‘Automatic Greasing’ (Special order option

only) refer to the manual <<General Instructions>> supplied with your

machine.

Greasing comes under the category of ‘work on the machine’.

Observe the safety rules.

10 2Greasingplanandintervals

*2 shots of grease

(A shot of grease is estimated to be approximately 4 grammes)

Operation and maintenance

gure 2.27

5

4

8

2

3

6

11

9

1

12

10

7

Loading...

Loading...