20

21

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUP

WWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

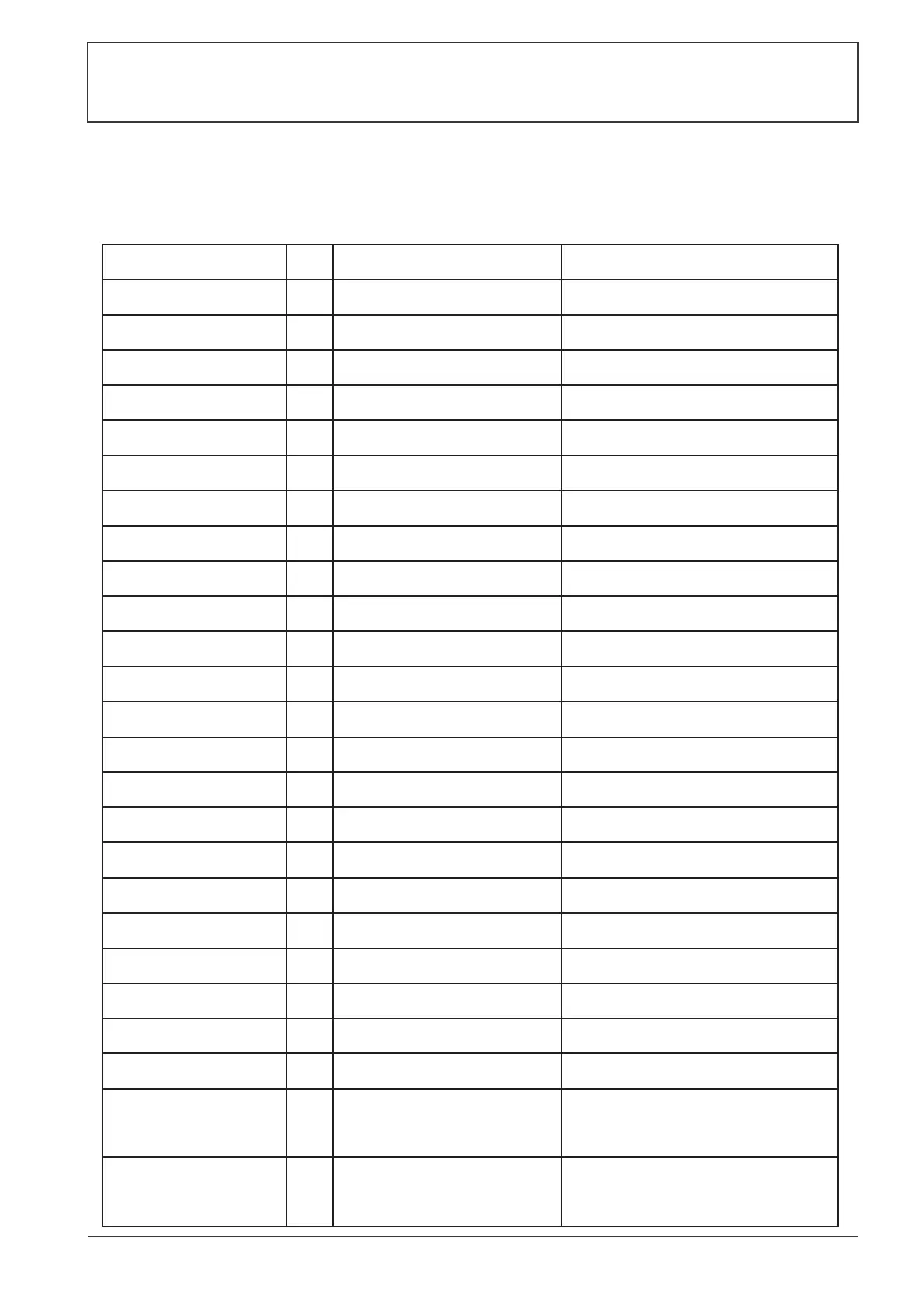

FREQUENCY CONVERSION BOARD FAULT TABLE:

Protect/fault

Discharge Temp. Senso r

Faul t

P01

P02

P04

P05

P07

E02

E07

E03

E29

E06

P1 5

P081

E05 1

E08

E1 9

E01

P082

Reaso n

P09

E05

F051

Check or change the temp. sensor

Check the pressure switch and cold circuit

PP

The ambient temp. is low

Water flow is not enough and low

differential pressur e

Water flow is not enough

The ambient temp. is low

The compressor is overload

Antifreeze temp. sensor is broken or

short circui t

Water temp.or ambient is too low

There is something wrong with fan

motor and fan motor stops runnin g

The pressure sensor is broken

F031

TP Ambient temp. is too low

E081

Check the communication connection

Check or change the pressure sensor or

pressure

Check or change the temp. sensor

Check or change the temp. sensor

Check or change the temp. sensor

Check or change the temp. sensor

Check or change the temp. sensor

Check or change the temp. sensor

Check the pressure switch and cold circuit

Check

the pipe water flow and water pump

Check the water temp. and ambient temp.

Check the pipe water flow and whether water

systemis jammed or not

Check the pipe water flow and whether water

system is jammed or not

Check the ambient temp.

sensor

Check the ambient temp.

sensor

Check the wire connection between remote wire

controller and main board

Check the ambient temp.

sensor

Check whether fan motor is broken or locked or

not

The temp. sensor is broken or short

circui t

The temp. sensor is broken or short

circui t

The temp. sensor is broken or short

circui t

The temp. sensor is broken or short

circui t

The temp. sensor is broken or short

circui t

The temp. sensor is broken or short

circui t

The temp. sensor is broken or short

circui t

Eliminatio n methods

Check whether the system of the compressor

runnin g normall y

No water/little water in water system

The high-preesu re switch is broken

Communication failur e between wire

controller andmainboar d

Speed control module and main

board communication fail

Amibent Temp. Senso r Faul t

Outlet Temp. Senso r Faul t

Coil 1 Tem

p. Senso r Faul t

Suction Temp. Senso r Faul t

Exhaus t Air over Temp Prot.

Inle t Temp. Senso r Faul t

Check whether the system of the compressor

runnin g normally

The compressor is overload

Coil 2 Temp. Senso r Faul t

Check or change the temp. sensor

The low-preesure switch is broken

1 . Motor is in locked-rotor state

2.Th e wire connection between

DC-fan motor module and fan motor

is in bad contact

1.Chang e a new fan motor

2.Chec k the wire connection and make sure

they are in good contact

Anti-freezing Prot.

Low Pressure Prot.

Flow Switch Prot.

Inlet and outlet temp. too big

High Pressure Prot.

Comp. Overcurrent Prot.

Communication Faul t

Primary Ant

i-freezing Prot.

Waterway Anti-freezing Prot.

EC fan feedback Faul t

Pressure Sensor Faul t

Fan Motor1 Faul t

Low AT Protection

Communication Faul t

(speed control module)

Antifreeze Temp. Sensor

Faul t

Secondar y Anti-freezing Prot.

Fault

display

F032Fan Motor2 Faul t

1 . Motor is in locked-rotor state

2.Th e wire connection between

DC-fan motor module and fan

motor is in bad contact

1.Chang e a new fan motor

2.Chec k the wire connection and make sure

they are in good contact

4.9.1Electronic control fault table

Can be judged according to the remote controller failure code and

troubleshooting.

4.9 Parameter list and breakdown table

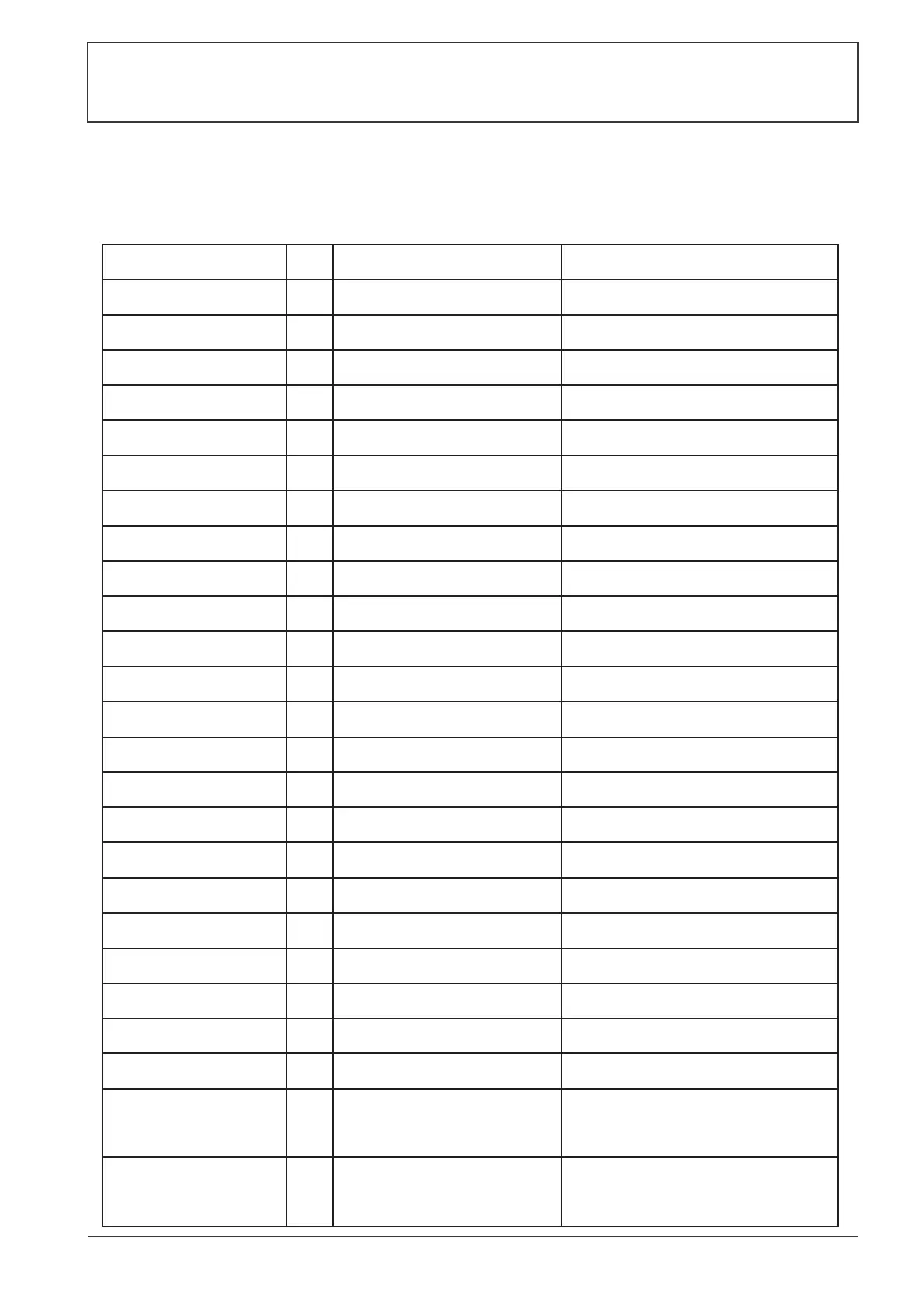

Protection/fault

F01

F02

F03

F04

F05

F06

F07

F08

F09

F1 0

F1 1

F1 2

F26

F27

F1 5

F1 6

F1 7

F1 8

F1 9

F20

F22

F23

F24

F25

MOP drive alar m

Frequenc y conversion board and

mainboard communication failur e

IPM modular protection

Lack of phase, step or drive hardware

damage

Motor current feedback open circui t

or short circuit

IPM Input current is large

DC bus voltage>Dc bus over-voltage

protection value

The input voltage is low,causing the

inpucurrent is high

The equipment load is too large

Check the communication connection

Recovery after the 150s

Check the input voltage measurement

Fault

display

Reaso n Eliminatio n methods

The input voltage lost phase

IP M sampling electricity is fault

The transducer is overheat

Transduce r temperature is too high

F28

Check the input voltage measurement

Check the input voltage measurement

Check the input voltage measurement

Check the communication connection

Check the PFC switch tube short circuit or

not

Check whether the unit is overloaded

Restart the unit after multiple power

failures, if the fault still exists, replace

the

compressor

The PFC circuit protection

DSP and PF C connectfault

The IPM module is overheat

Compressor magnetic force is not

enough

Check and adjustthe current measure ment

Check and measure the voltage adjustment

Check and adjus t the current measurement

The compressor over-current protection

Check whether the chip is damaged,replace

the chip

Compressor electricityis larg e

Inpu t current is too large

MCU error

The V15 V is overload or undervoltage

Check the V15 V input voltage in range

13.5v~16.5 v or not

Check whethercurrentreturn wires

connectedmotor

Check themeasurin g voltage , check

requency conversion boardhardware

DC bus voltage<Dc bus over-voltage

protection value

The input voltage is too high,more than

outage protection current RMS

The input voltage sampling fault

Check and adjustthe current measure ment

Recovery after the 150s

Check and adjustthe current measure ment

Check and adjus t the current measurement

Check and adjus t the current measurement

Check and adjus t the current measurement

Check or change the temp. sensor

The temp. sensor is broken or

short circui t

Drv1 MOP alar m

Inverter offline

IPM protection

Comp. Driver Failur e

DC Fan Faul t

IPM Overcurrent

Inv. DC Overvoltage

Inv. DC Lessvoltag e

Inv. Input Lessvolt.

Inv. Input Overvolt.

Inv. Sampling Volt.

Comm. Err DSP-PF C

Input Over Cur.

PFC fault

IPM Overheating

Weak Magnetic Warn

Inv. Input Out Phas e

IPM Sampling Cur.

Inv. Temp. Probe Fail

Inverter Overheating

Inv. Overheating Warn

Comp. Over Cur. Warn

Input Over Cur. Warn

EEPROM Error Warn

V15V over/undervoltage fault

SWIMMING POOL HEAT PUMP TYPE SP

SWIMMING POOL HEAT PUMP TYPE SP

Loading...

Loading...