7

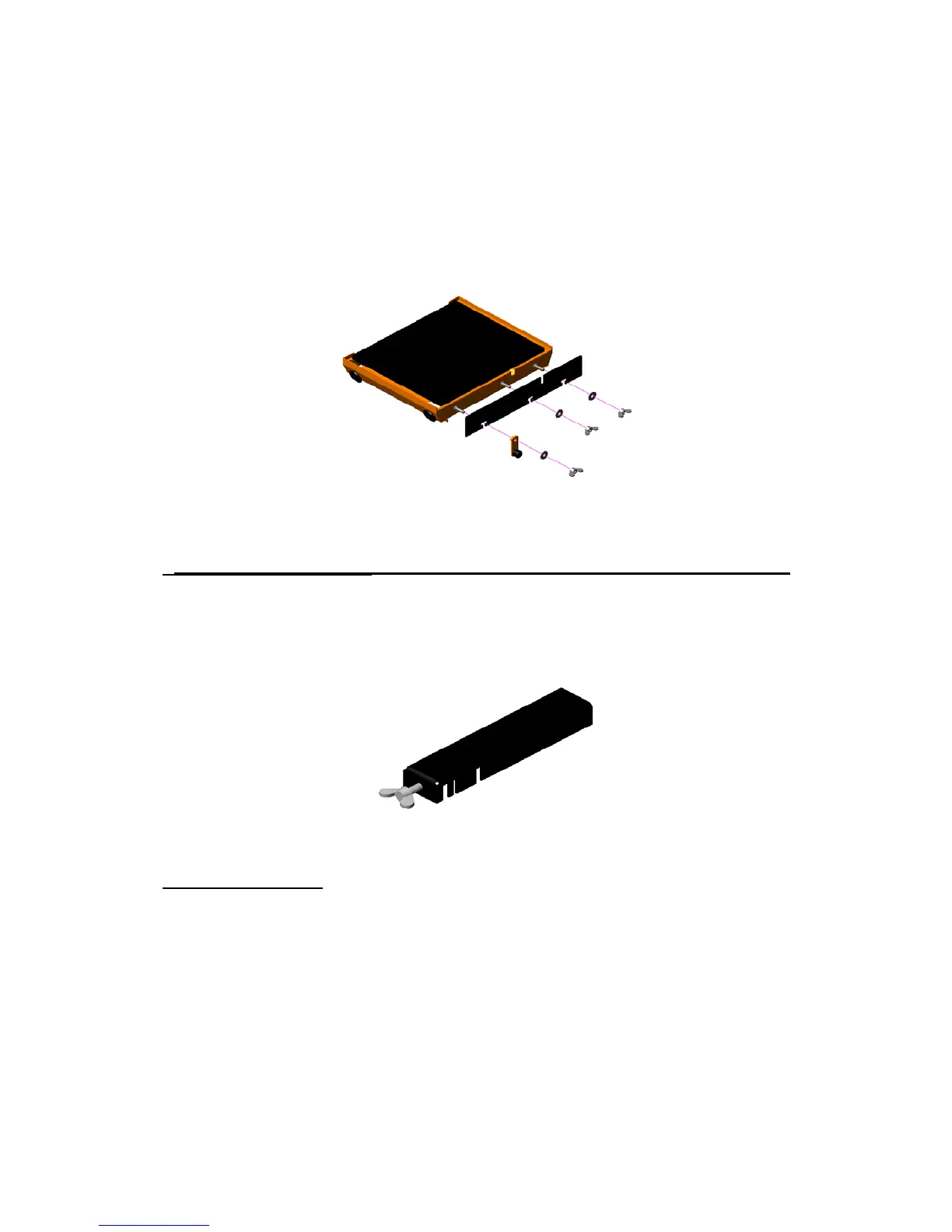

Conveyor Cart Assembly:

Remove the Conveyor Cart and Back Stop from the Saws Water Pan, and the

Wing Nuts, Carriage Bolts, Washers, and Cart Stop from the plastic bag. Slide

one (1) Carriage Bolt thru each of the three (3) Square Holes located on the

front of the Conveyor Cart. Slide the Back Stop Over each of the Carriage

Bolts. Slide the Stop Assembly over the Carriage Bolt Located on the Left front

of the Conveyor Cart NOTE: The Rubber Stop will faces away from the

Conveyor Cart. Attach one (1) Washer and one (1) Wing Nut to each Carriage

Bolt and Tighten. See Figure 1: Back Stop Assembly. Place the Conveyor

Cart on the Machine.

Figure 1: Back Stop Assembly

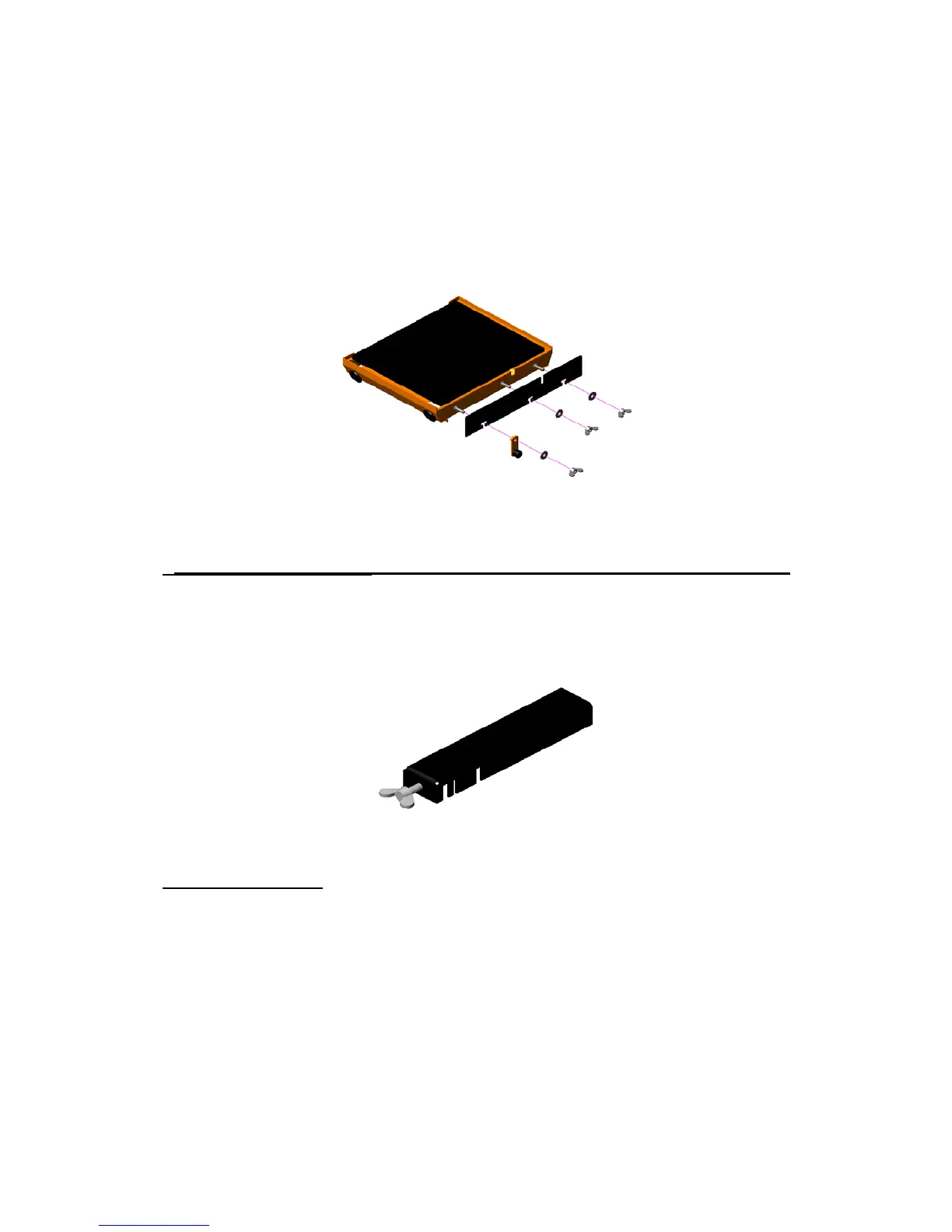

Guide-A-Cut Assembly:

Attach the Guide-A-Cut to the Conveyor Cart by adjusting the Wing Bolt until

the Guide-A-Cut can slide over the Black Stop. The Guide-A-Cut will work as a

Rip Guide that is adjustable for 90 and 45 cuts. See Figure 2: Guide-A-Cut

Assembly.

Figure 2: Guide-A-Cut Assembly

Splash Assembly:

Remove the Splash Guard from the Saw Water Pan. Attach the Splash Guard

Spring Clips to the Pivoting Bar Located Under the Cutting Head. Note that the

rough side of the Splash Guard should face towards the front of the saw. The

Splash Guard material is made is designed for easy to cleaning. To clean,

simply rinse the Splash Guard with water until clean. The Splash Guard should

be used when wet cutting to reduce the amount of debris thrown from the blade

and cutting surface. When dry cutting the Splash Guard can be removed to

allow the dust particles to drift away from the Saw Operator.

Loading...

Loading...