—4—

e Novitool® Aero® is the premier, state-of-the-art splice press for splicing thermoplastic conveyor belts

(e.g. PVC, Polyurethane), with the following features:

• Press is compatible with multiple power sources.

See pages 5 and 6 for specics.

• Internal electronic controls

• Top and bottom temperatures can be set independently

up to max. 392 ˚F (200 ˚C)

• Internal splice value recipe database

• Splice pressure is applied by an internal compressor,

max 28psi (2 bar)

• Preheat function

• Forced air cooling technology in both top and

bottombeams

Description

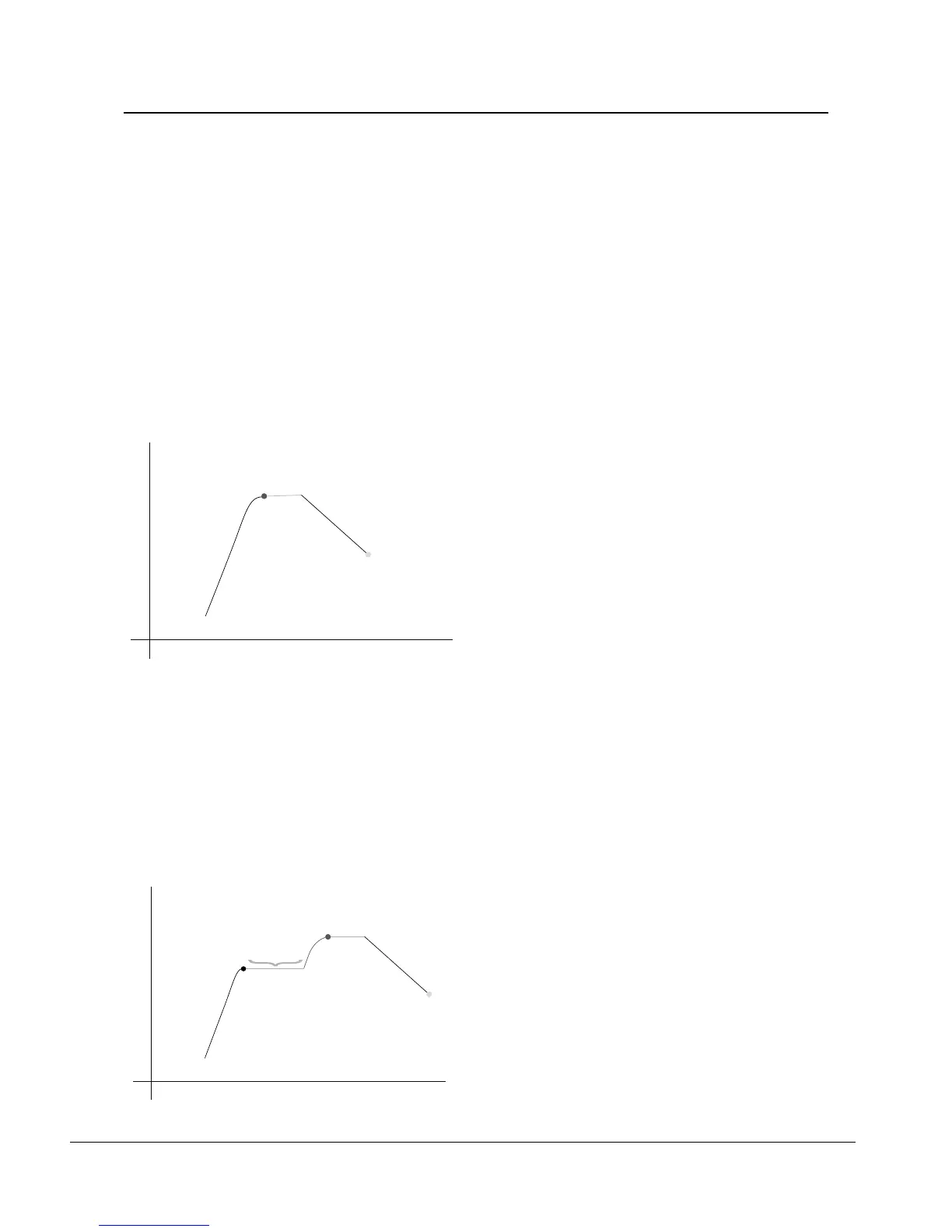

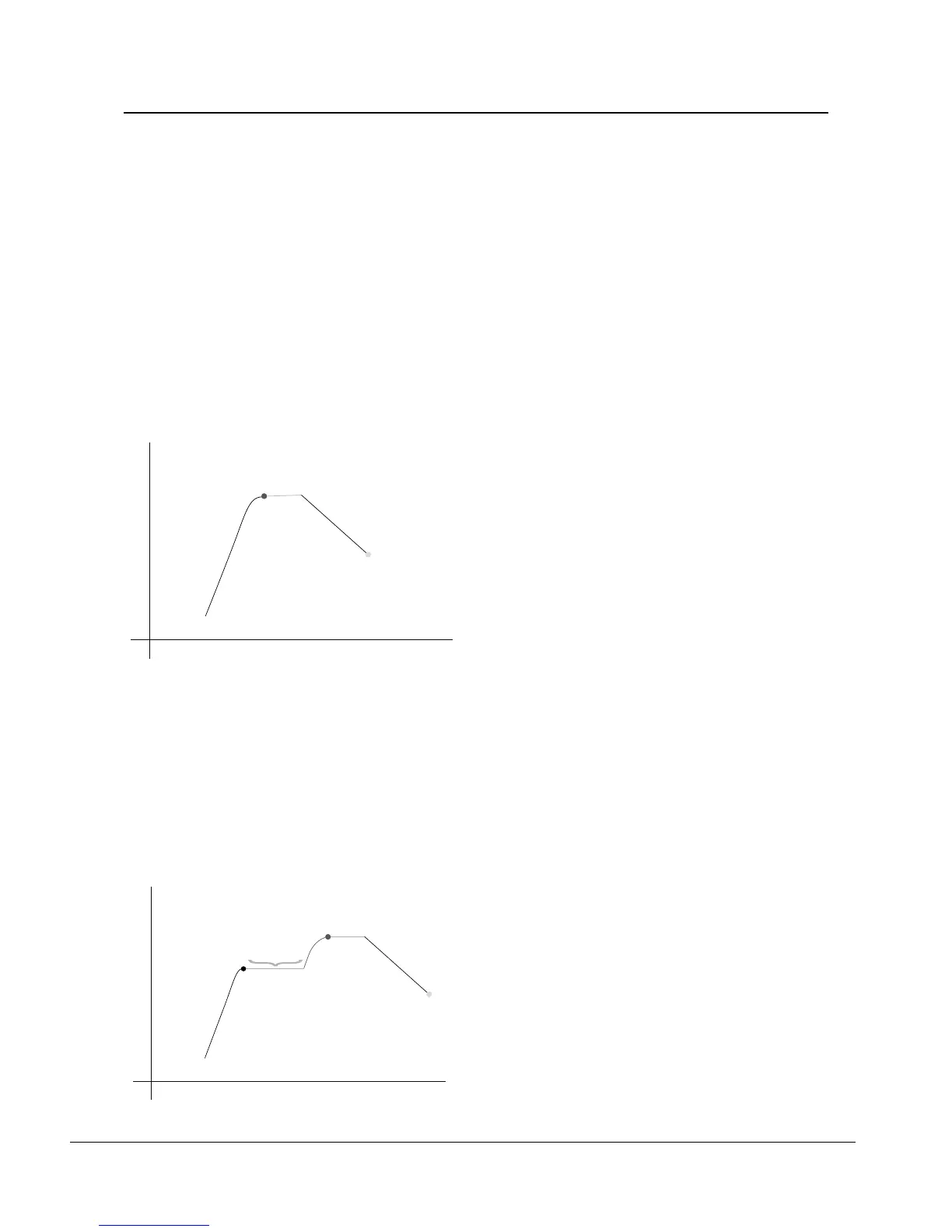

Understanding Preheat Function

If belt is relatively thick, a problem might occur where the outside of the belt is at the splicing temperature too

long, waiting for the inside to reach the required temperature. Melted material might ow away or discolor

and fabrics might shrink. To avoid this problem, the preheat option can be used. is option heats the belt

up (outside and inside) to a temperature just below the melting temperature. Aer the preheat stage, the

inside splice temperature can be reached much quicker, minimizing the risk for unwanted ow of material,

discoloring or shrinkage.

time

temperature

Settings:

splice temperature

dwell time

cool down temperature

(fans turn off)

pre-heat

temperature

pre-heat

dwell time

time

temperature

Settings:

splice temperature

dwell time

cool down temperature

(fans turn off)

Loading...

Loading...