—9—

General Safety Rules – Save These Instructions

!

CAUTION

e Aero has been optimized for process speed,

portability, and ease of use. A resulting aect of the

designed portability is that the structure will deect

as internal air pressure is increasing during splice

process. e length of press will determine how

much deection will occur at any specic pressure.

Beam extrusions were designed with strength

to return to their normal state when pressure is

relieved; deection will not be permanent.

Press Lifting and Rigging Guidelines

e following guidelines should be used to li an Aero press when using equipment to assist:

1. Determine the approximate center of gravity for liing safety before liing the press.

2. Always test-li the press to determine the exact unit balance and stability before hoisting it to full height.

3. Ensure that all liing equipment is operated by qualied personnel.

4. Ensure the rigging equipment and material have the required capacity for the job and that all items are in good

condition.

5. ese instructions are recommendations only as other congurations may be more suitable than shown based

on rigging equipment used.

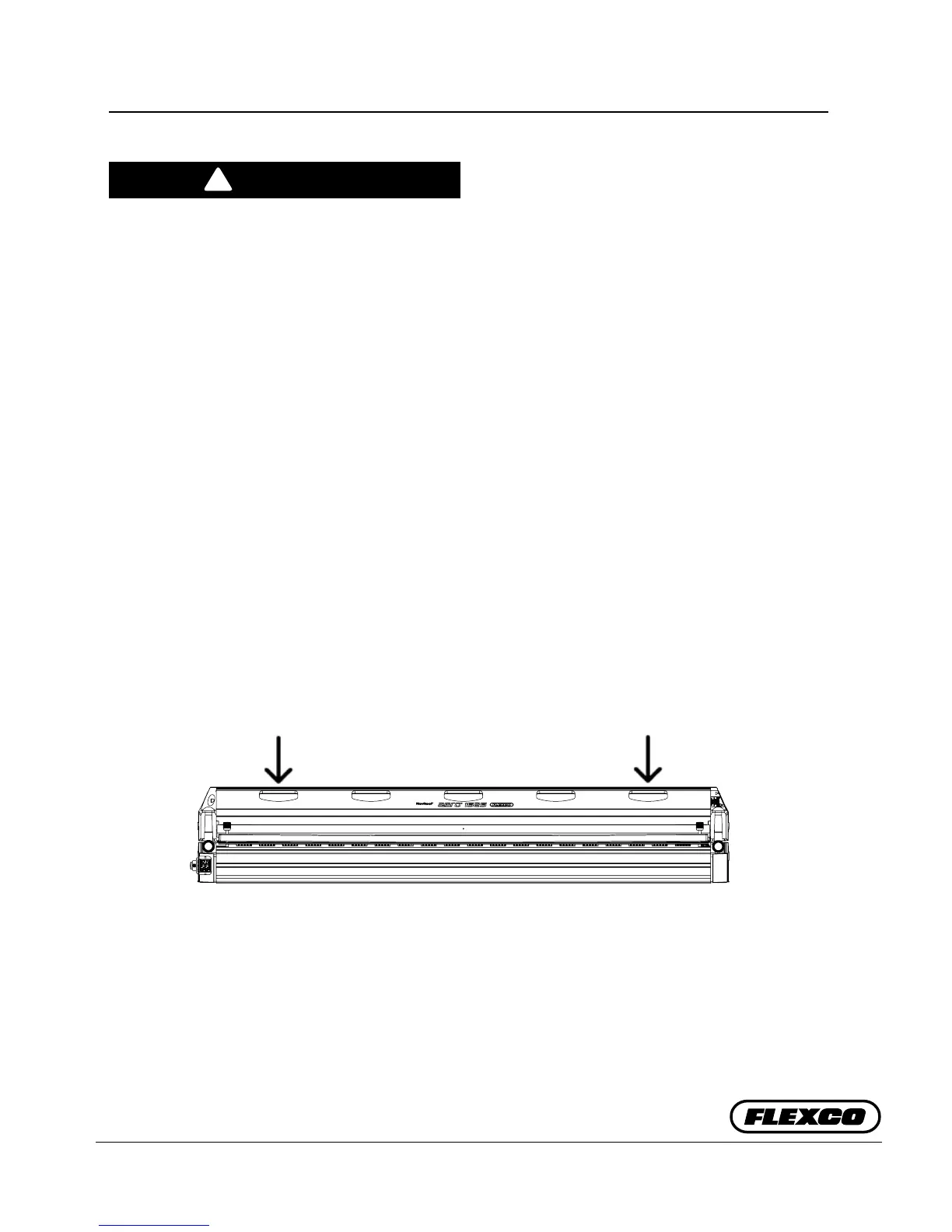

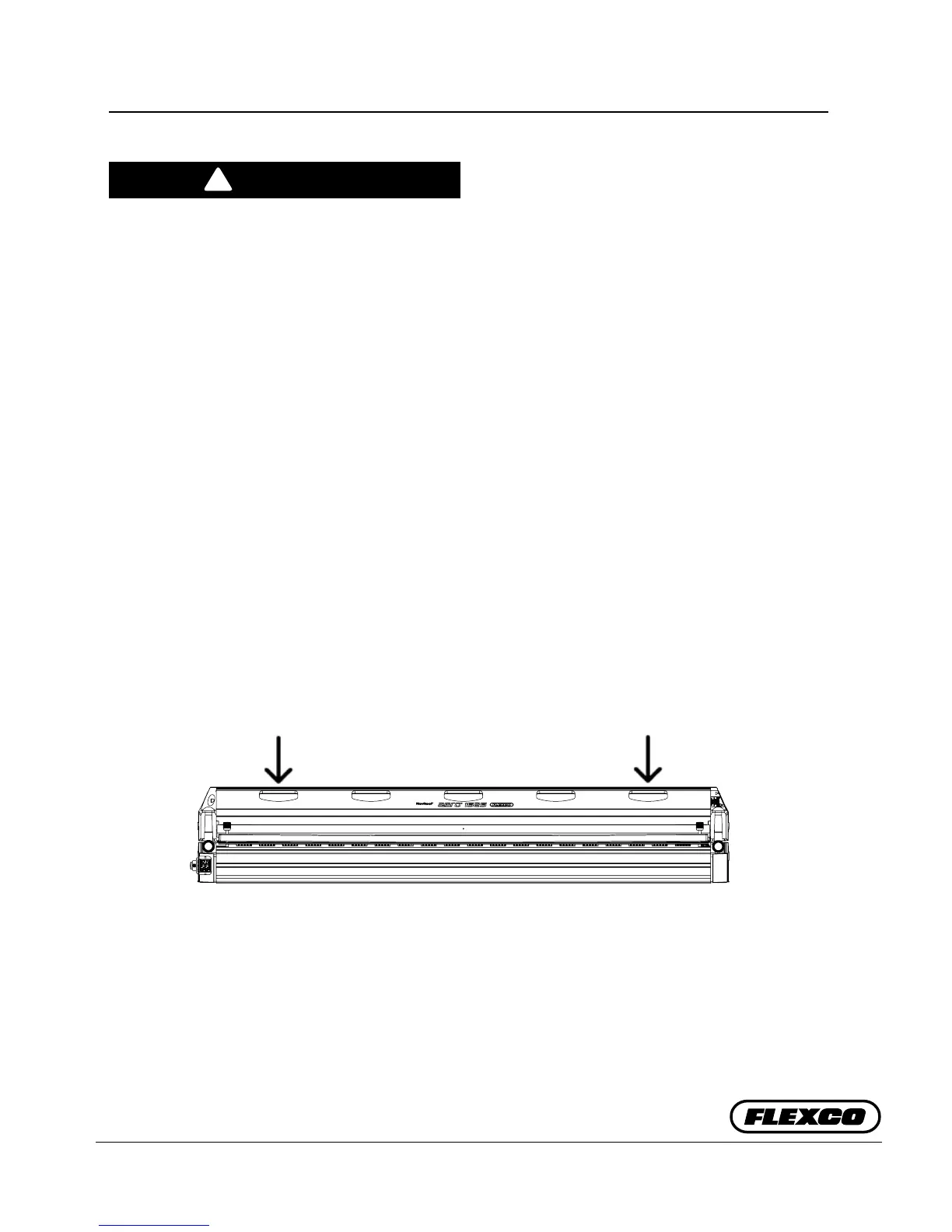

6. e upper beam fan inlet holes may be used as liing locations with straps. Attach two straps through the two

furthest outside vent holes in the upper extrusion. Ensure the bottom beam connector bolts are secured.

Loading...

Loading...