●

Sensor Shaft Mounting Procedure

Item Description Remarks

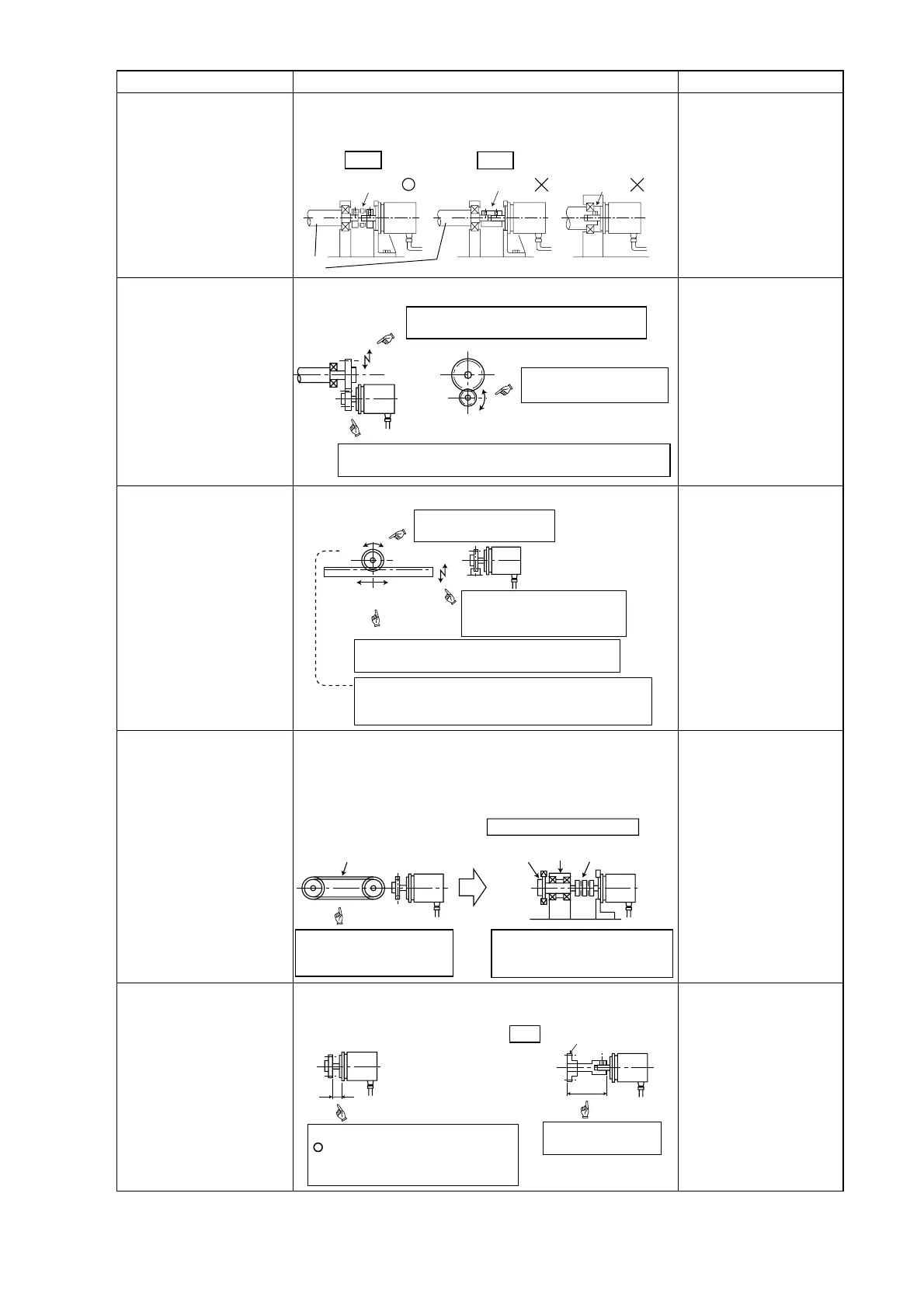

(1) Coupling of Machine

shaft and Sensor shaft

① Be sure to use a coupling device to link the 2 shafts.

(Refer to Appended Fig.1 for the recommended coupling

device specifications.)

A `direct-link` format

will result in shaft

fatigue and/or breakage

after a long periods.

Therefore, be sure to use

a coupling device to link

the shafts.

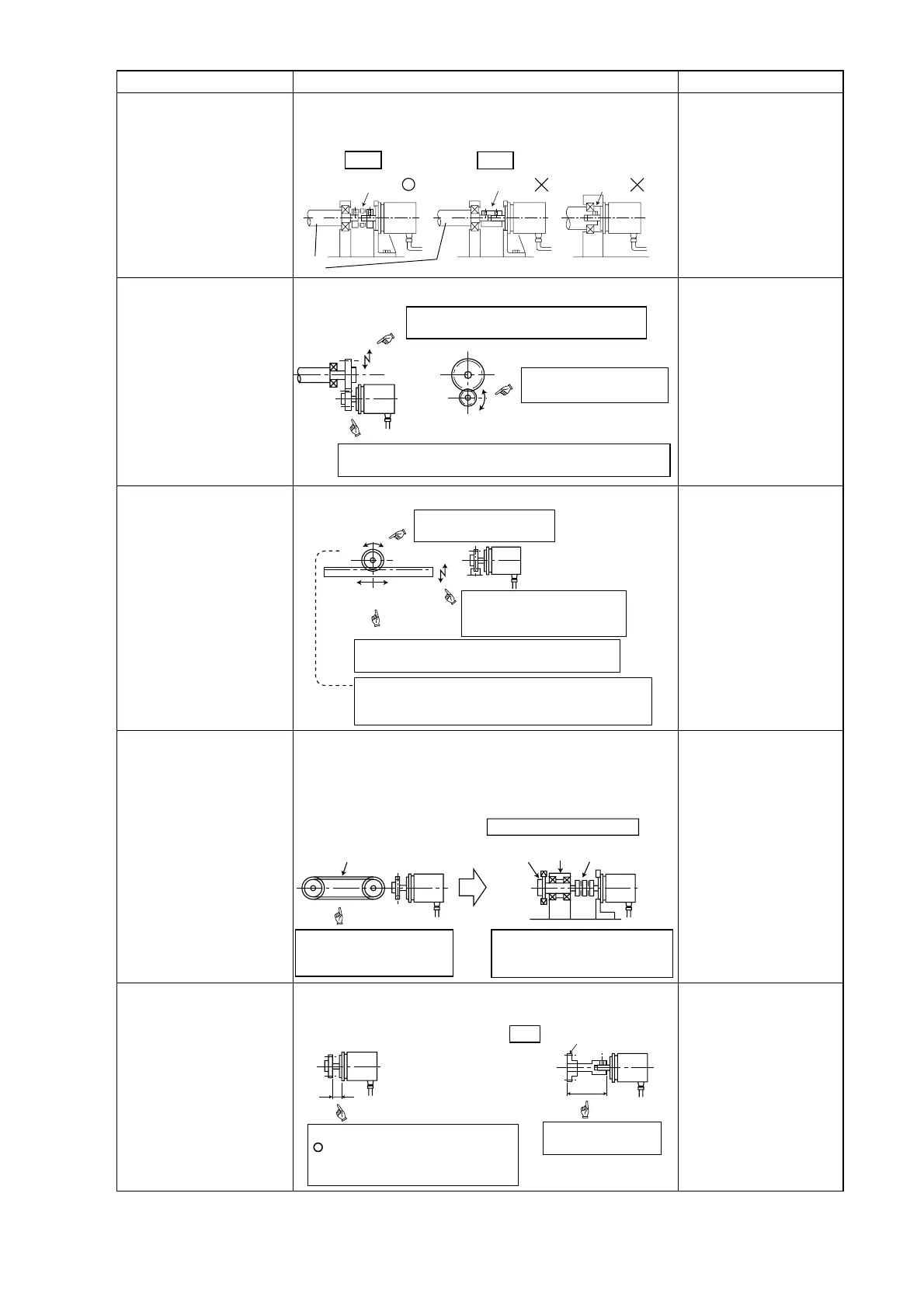

(2) For gear-type linkage

① If a gear linkage is used, be sure that some backlash exists.

Incorrect gear mounting

can result in gear

bending or breakage.

(3) For rack-and-pinion

type linkage

① Be sure that backlash exists at all rack positions.

Incorrect

rack-and-pinion

mounting can result in

gear bending or

breakage.

(4) For chain or pulley

linkage

① When a chain or pulley linkage format is used, there is an

inherent risk of the shaft’s load being increased by the

resulting tension.

Therefore, a bearing should be used, with the shafts being

linked by a coupling device immediately behind the bearing.

(5) Shaft mounting

position

① The shaft should be attached to the coupling device or gear

at a point which is as near to the Sensor body as possible.

●B-4●

OK

NG

Coupling device

Direct link

Direct link

Shaft

Be sure that the distance between shafts will not

be altered by vibrations, shocks, etc.

Be sure that backlash exists

at all gear positions.

The Sensor shaft pinion should be as light (small) as possible. This

is especially true for environments where vibration/shocks are likely.

Be sure that backlash exists

at all rack positions.

Be sure that the distance between

the rack and pinion will not be

altered by vibrations, shocks, etc.

Be sure that the distance between the rack and pinion is

not altered when horizontal motion of the rack occurs.

The Sensor shaft pinion should be as light (small) as possible.

This is especially true for environments where vibration/shocks

are likely.

Recommended linkage format :

Chain

Bearing

Coupling device

Chain

sprocket

Even a small amount of tension

can produce a considerable load

on the shaft.

This linkage format is also applicable

to the ’rack-and-pinion’ and ’gear’

methods shown above.

NG

Coupling device

or gear

Never use an extended

shaft format.

This distance should be as short as possible.

When this distance is short, the load

placed on the bearing by

vibrations/shocks is slight.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...