Bottle Cap

lrrigation

Tube Needle

Tube Clamp

Tube Cap

Power Switch

Symbol Mark

Function OFF ON

6-1 Programming the micromotor operation

The control unit can memorize 10 sets of programs. Each program includes the following

functions which will be automatically performed when the appropriate program number is

selected.

Gear ratio of contra angle handpieces

Speed

Direction of rotation

Torque upper limit

Coolant solution flow

a Turn on the power by pushing the main switch toward [

-

].

Whenever the main power switch is turned ON, program

number 1 is always displayed.

s Select a program number by using either step a) or step b):

O a Press the [Program] key on the unit control panel

until the program number you require is displayed OR

O b Press the [Program] button on the foot control until the program number

you require is displayed.

d Selecting the gear ratio of the handpiece relevant to the program

Press the [Gear Ratio] key the gear ratio of the handpiece to be used is displayed.

f Setting the speed

Set the speed by pressing the [Speed] key.

-Each time this key is pressed the display changes to the next speed level. By pressing this key

for more than 1 second brings the speed quickly to the next level until the speed display

reaches its upper or lower limit.

-When the speed setting reaches the upper or the lower limit, an audible beep is heard and the

speed setting cannot be changed any further.

g Setting the torque upper limit

Set the torque upper limit by pressing the [Torque] key on the unit control panel.

-Each time this key is pressed the display changes to the next torque level. By pressing this key

for more than 1 second brings the torque quickly to the next level until the torque display

reaches its upper or lower limit.

-When the torque setting reaches the upper or the lower limit, an audible beep is heard and the

torque cannot be changed any further.

h Select the rate of coolant solution flow volume

Select the rate of the coolant solution flow volume by pressing the [Coolant Flow] key.

-The rate of coolant solution flow volume has 5 flow rate steps plus "no coolant flow".

j Memorize settings

After completing steps 1-6 press the [Memory] key for more than 1 second until a long

audible beep is heard. The long beep confirms that the programming is completed. If you hear a

short audible beep when the [Memory] key is first pressed please ignore this signal and

keep the [Memory] key depressed until a long beep is heard.

Repeat the above steps 1-7 to program any one of the 10 available programs.

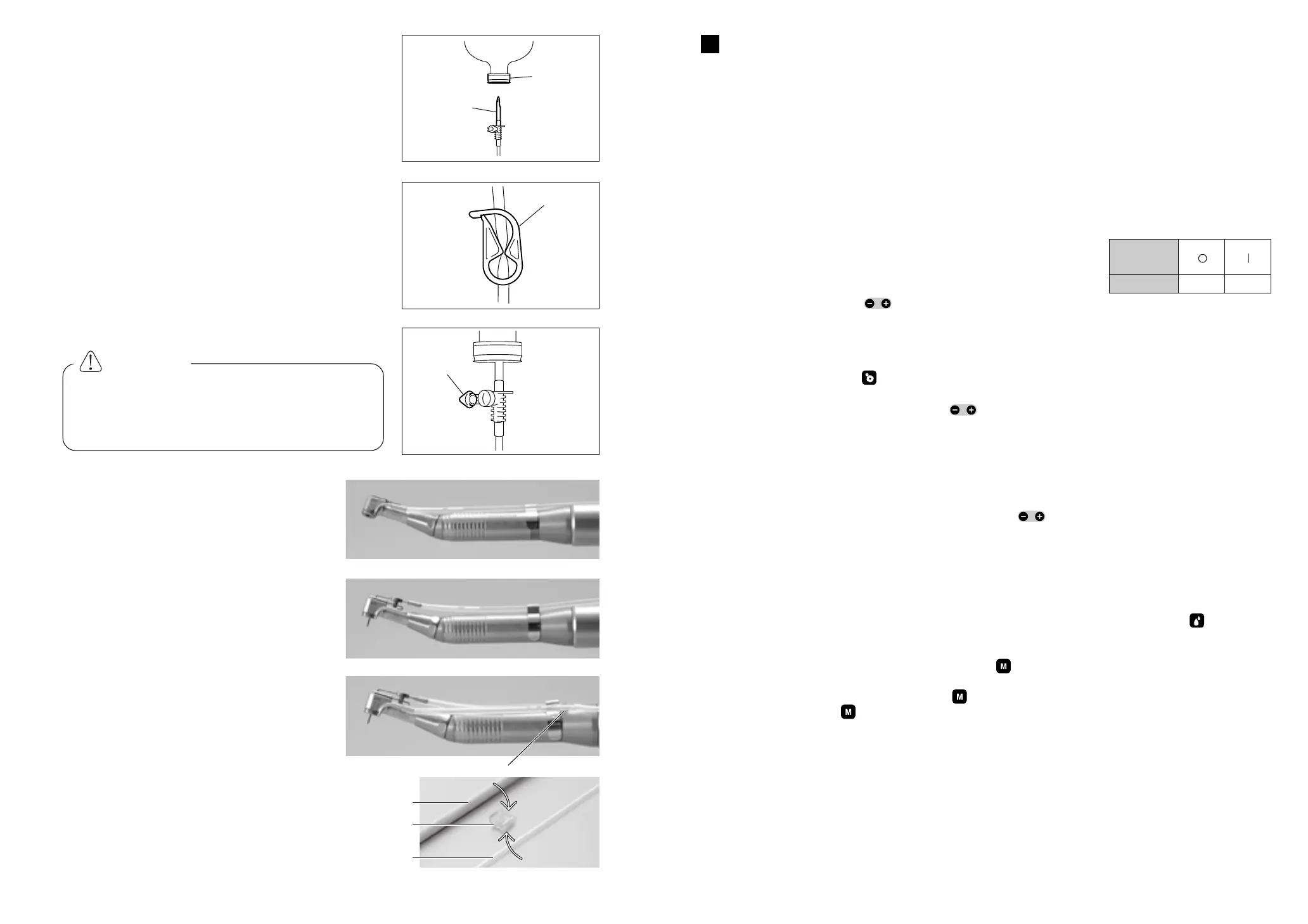

5-6 Insertion of the irrigation tube

a Place the coolant solution bottle on the hanger post

and insert the irrigation tube needle into the bottle

cap. (Fig.11)

s Close the tube clamp, between the irrigation tube

needle and the irrigation pump, as shown in Fig.12

d Open the tube cap to supply air into the bottle.

(Fig.13)

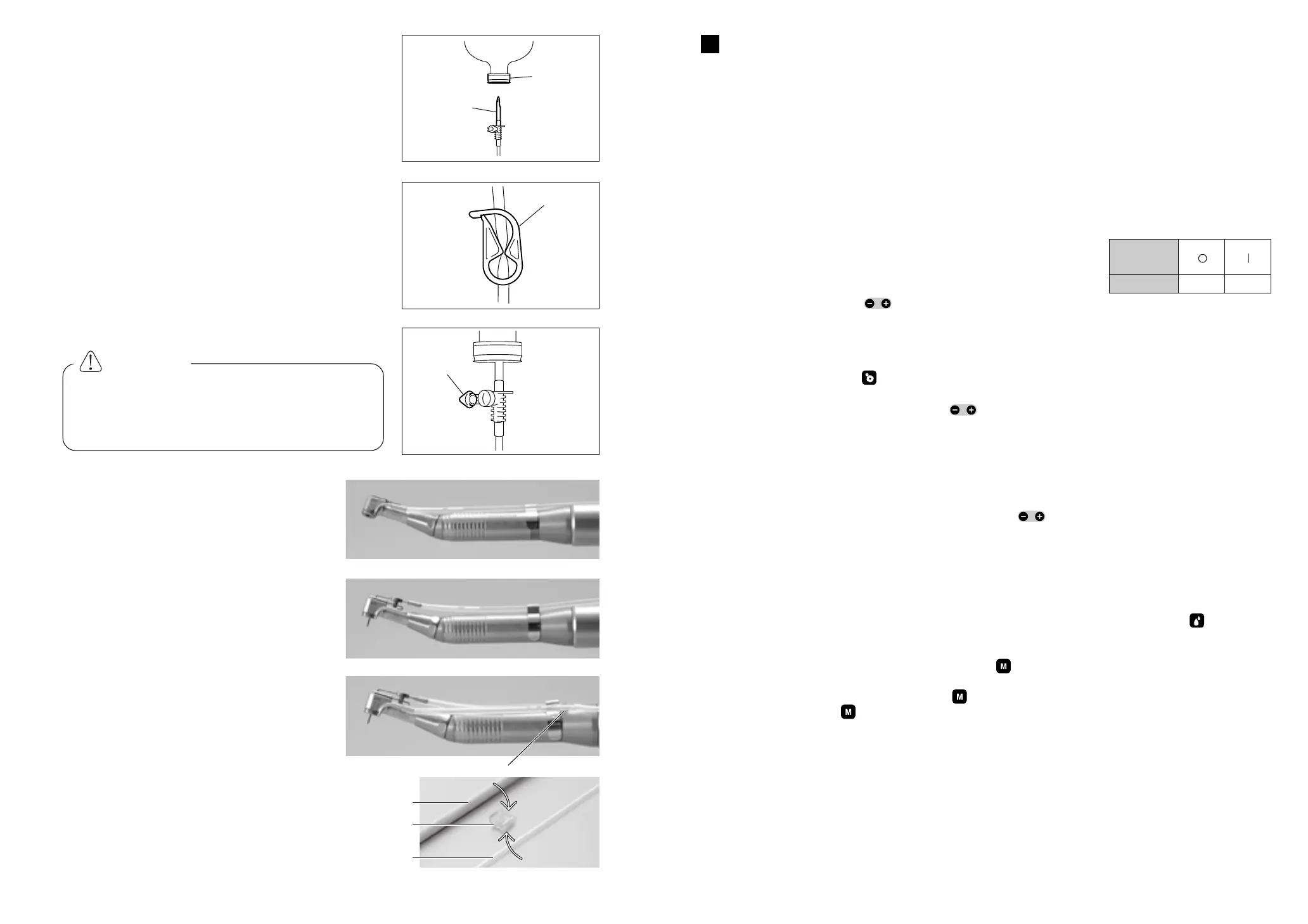

5-7 Mounting the internal spray nozzle

It is possible to connect water to the external

irrigation nozzle (Fig.14) and the internal

irrigation nozzle (Fig.15) simultaneously.

Simply connect the Y connector (Fig.16) onto

the main water supply tube at the rear of the

handpiece then connect the 2 water supply

tubes.

5-8 Attaching the tube holder

Use the tube holder to combine together the

motor cord and the irrigation tube. It is easier

to insert motor cord first and, next, the

irrigation tube.

Operation

6

oi

CAUTION

Do not operate the irrigation pump if the

tube is bent or the tube clamp is in the

closed position. This could cause the tube

to burst or slip out of the bottle.

Fig.11

Fig.12

Fig.13

Fig.14

Fig.15

Fig.16

Fig.17

Motor cord

Tube holder

Irrigation tube

Y-connector

PROGRAM

SPEED

TORQUE

Loading...

Loading...