Trinity Lx │Installation and Operation Instructions Lx Series

14

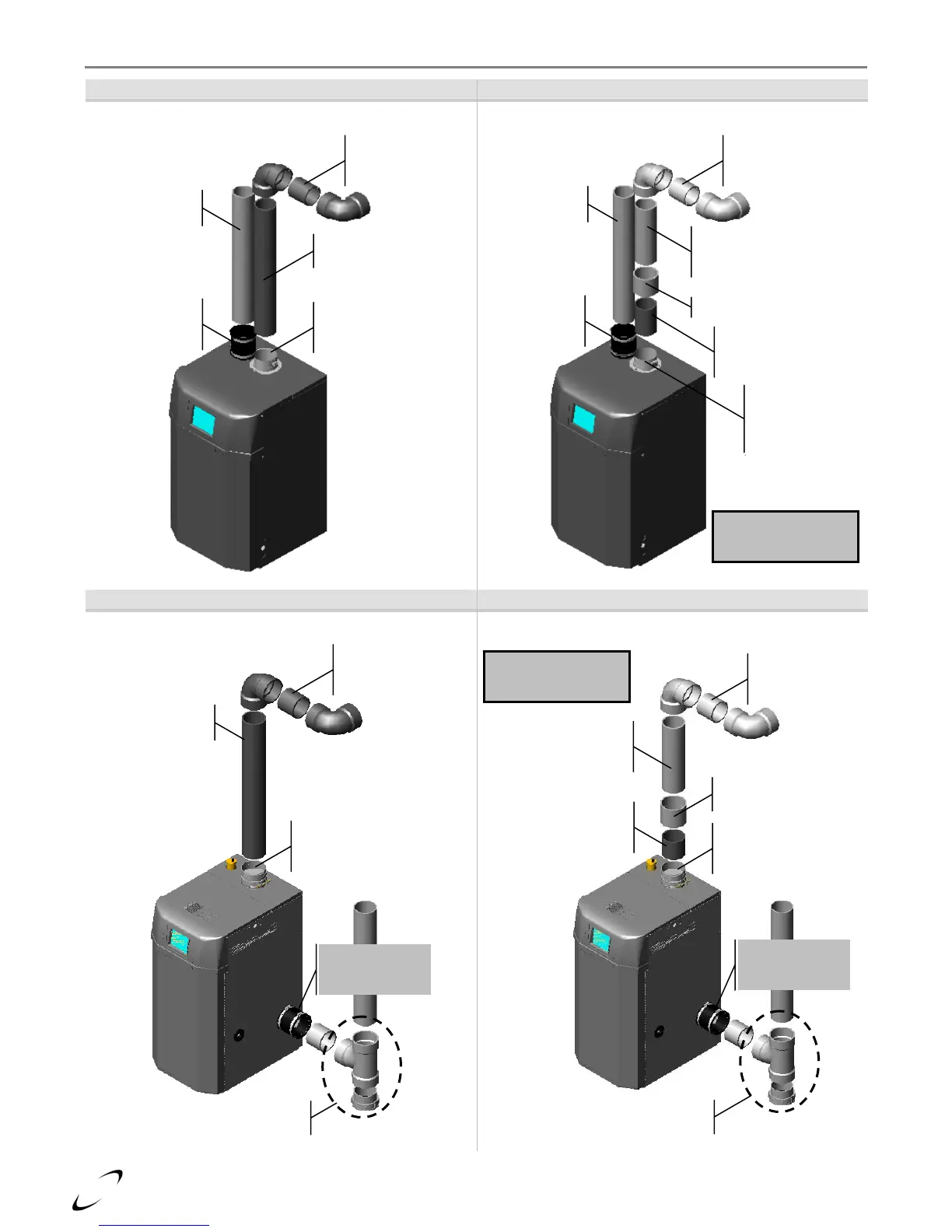

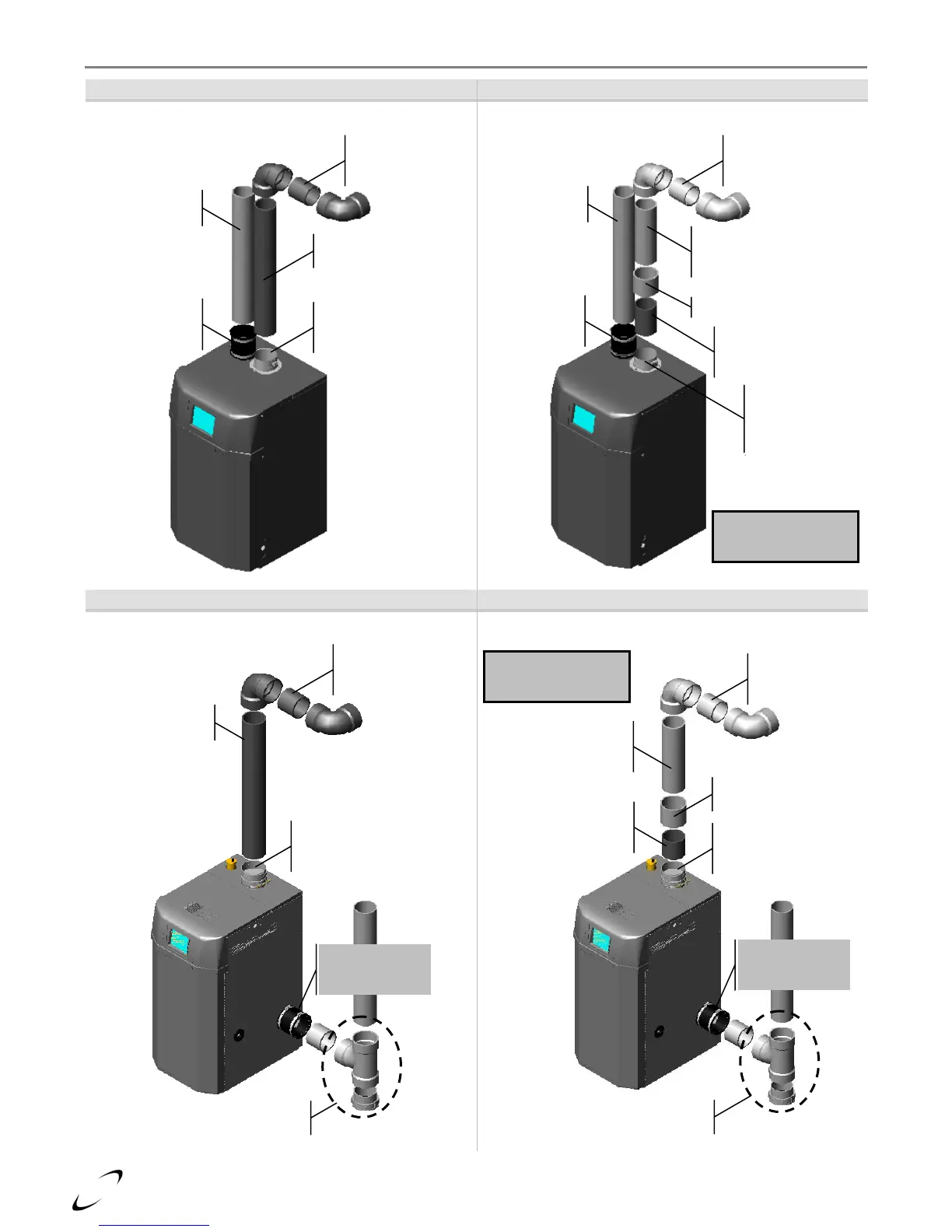

Figure 4-1(a) Lx150-200 Model Figure 4-1(b) Lx150-200 Model

Near Appliance Venting (CPVC) Near Appliance Venting (PVC)

Figure 4-2(a) Lx300-400 Models Figure 4-2(b) Lx300-400 Models

Near Appliance Venting (CPVC) Near Appliance Venting (PVC)

Air-Inlet - check with applicable local codes for acceptable pipe material.

Flue Outlet

Stainless Steel Adapter

(factory supplied)

Exhaust Vent

3” CPVC

Swing Joint

to attain slope in

horizontal runs

Air Inlet

3” Pipe *

Coupling

3” Removable

(field supplied)

Ai

-Inlet

4” Pipe *

Swing Joint

to attain slope in

horizontal runs

Exhaust Vent

4”/6” CPVC

Flue Outlet

Stainless Steel Adapter

(factory supplied)

Coupling

4” Removable

(factory supplied)

90

o

elbow typical, or tee and

drain cap option for easy cleanouts

ir Inlet

3” Pipe *

Coupling

3” Removable

(field supplied)

Swing Joint

to attain slope in

horizontal runs

Exhaust Vent - 3” PVC,

(check local codes and

Table 4-3)

Coupling 3” PVC

UE OUTLET

Transition Piece

3” CPVC, minimum 5”

long (factory supplied)

Mandatory Vent Pipe

Transition Piece

See Table 4-2.

i

-Inlet

4” Pi

e *

Swing Joint

to attain slope in

horizontal runs

Coupling

4”/6”x4” PVC

Flue Outlet

Stainless Steel Adapter

(factory supplied)

Coupling

4” Removable

(factory supplied)

Exhaust Vent

4”/6” PVC (check local

codes and Table 4-3)

Transition Piece

4” CPVC, minimum 4”

long (factory supplied)

90

o

elbow typical, or tee and

drain cap option for easy cleanouts

Mandatory Vent Pipe

Transition Piece

See Table 4-2.

Loading...

Loading...