Lx Series Installation and Operation Instructions │Trinity Lx

15

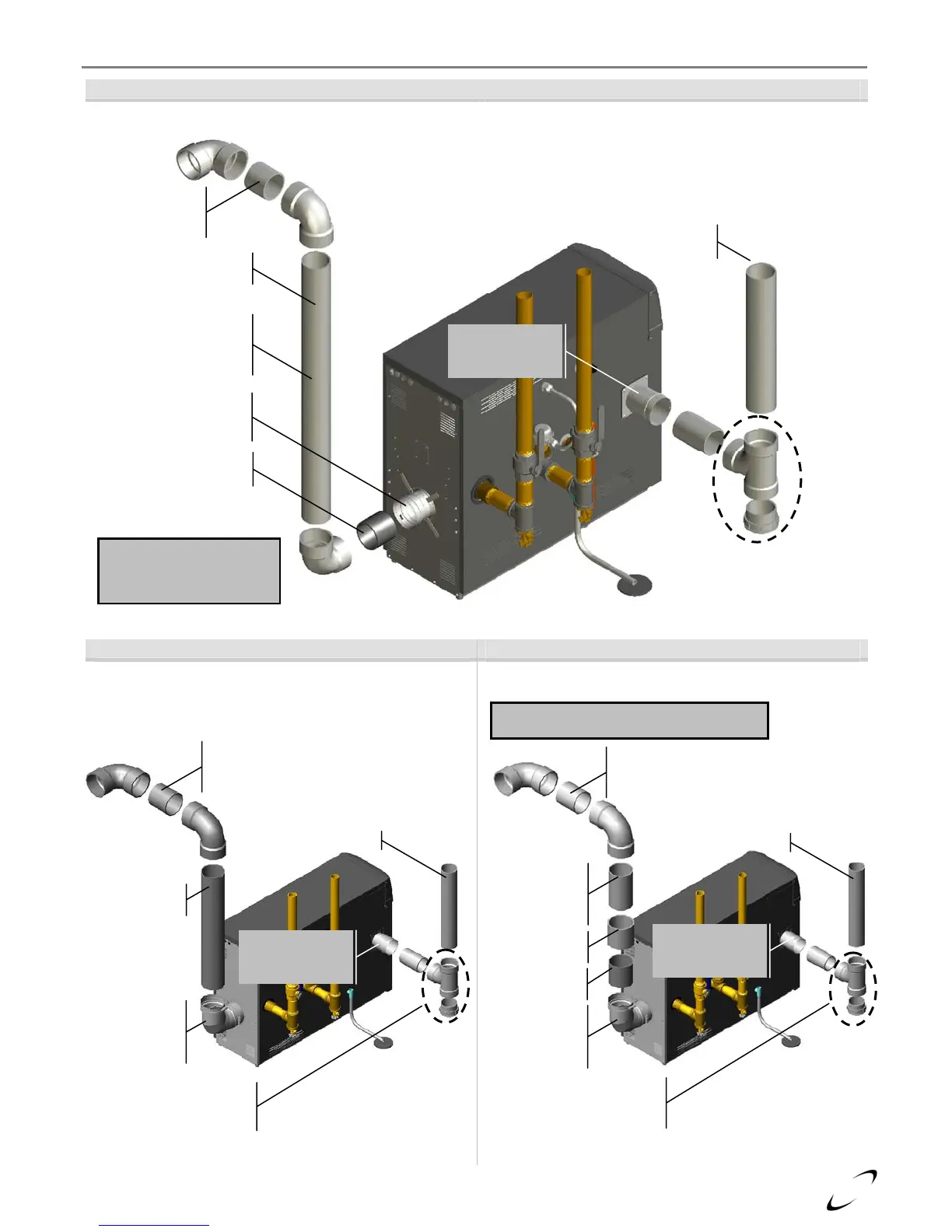

Figure 4-3(a) Lx500-600

Near Appliance Venting (CPVC/PVC)

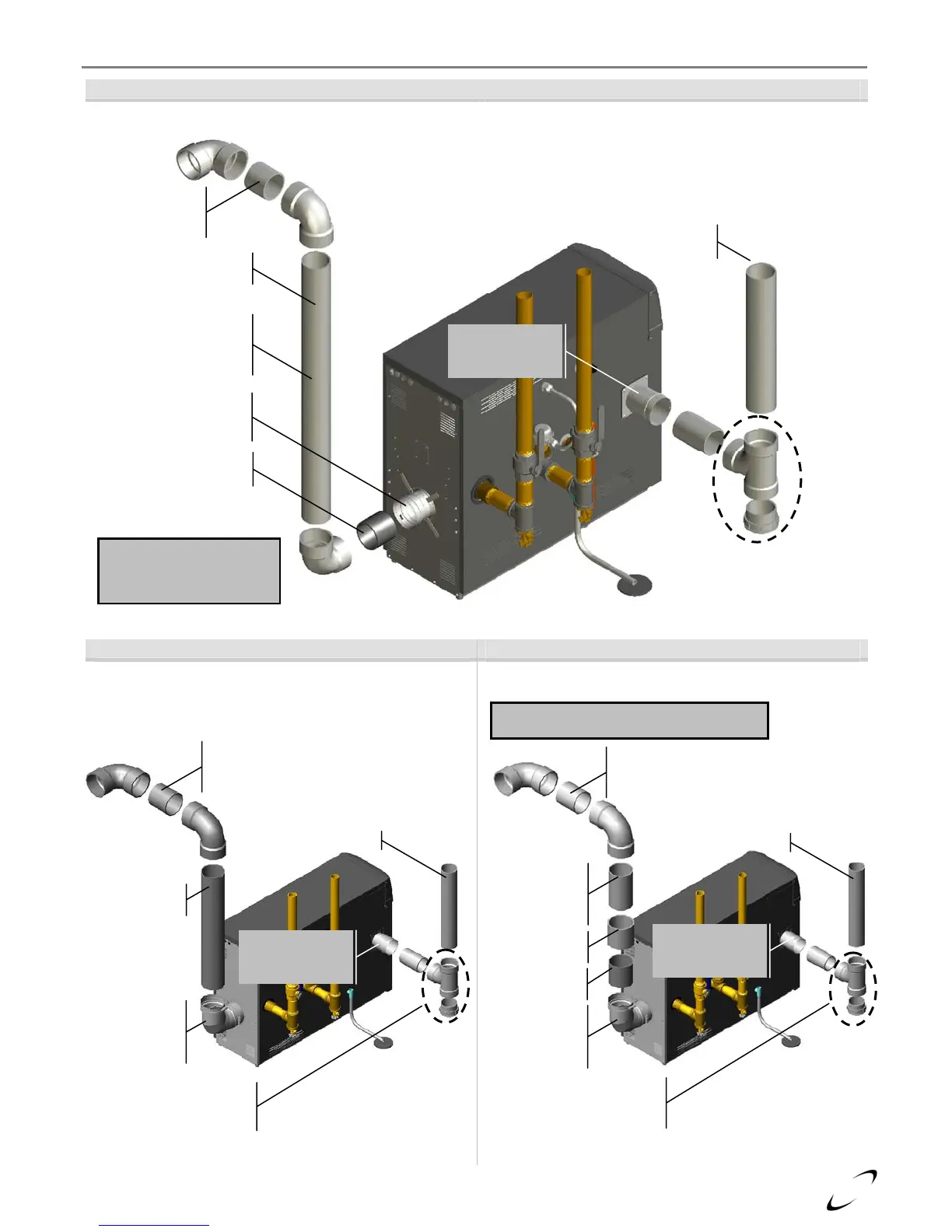

Figure 4-4(a) Lx700-800 Figure 4-4(b) Lx700-800

Near Appliance Venting (CPVC) Near Appliance Venting (PVC)

Air-Inlet - check with applicable local codes for acceptable pipe material.

Ai

-Inlet 4” Pipe *

Exhaust Vent

6” CPVC

Swing Joint

to attain slope in

horizontal runs

Flue Outlet 6”

stainless steel

elbow (factory

supplied)

Air-Inlet Adapter

4” stainless steel

(factory supplied)

90

o

elbow typical, or tee

and drain cap option for

eas

cleanouts

Air-Inlet Adapter

4” stainless steel

(factory supplied

90

o

elbow typical, or tee

and drain cap option for

easy cleanouts

Flue Outlet 6”

stainless steel

elbow (factory

supplied)

Exhaust Vent

6” PVC (check

local codes

and Table 4-3)

Coupling 6”

PVC, length 4”

i

-Inlet 4/6” Pipe *

Transition

6” CPVC

Swing Joint

to attain slope in

horizontal runs

Mandatory Vent Pipe Transition Piece

6” CPVC (factory supplied). See Table 4-2.

i

-Inlet

4” Pipe *

Exhaust Vent

4” CPVC

Swing Joint

to attain slope in

horizontal runs

Flue Outlet 4”

stainless steel

(factory supplied)

Air-Inlet Adapter

4” stainless steel

(factory supplied)

90

o

elbow typical, or tee

and drain cap option for

eas

cleanouts

Exhaust Vent

4” PVC (check

local codes

and Table 4-3)

Mandatory Vent Pipe

Transition Piece

4” CPVC (factory supplied).

See Table 4-2.

Transition

4” CPVC

OR

Loading...

Loading...