Trinity Lx │Installation and Operation Instructions Lx Series

16

Exhaust venting must be supported to reduce strain on piping joints. Failure to

follow these instructions may result in result in damage, serious injury or death.

In Canada, the first 3 ft (915 mm) of vent piping must be readily accessible for inspection.

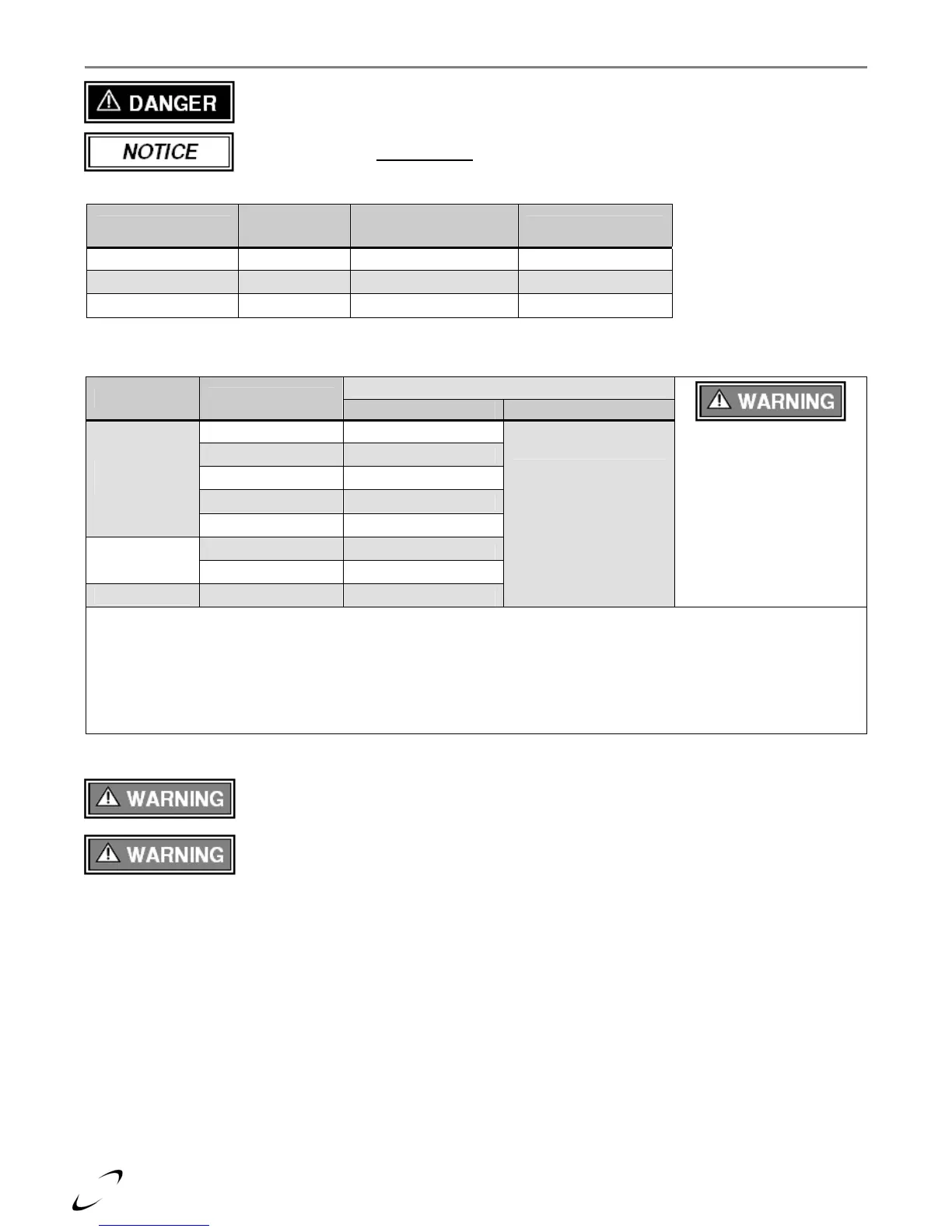

Table 4-2 Mandatory Vent Pipe Transition Piece

Model No.

CPVC Vent

Pipe Size

CPVC Transition Vent

Pipe Length

Full Insertion Depth

Trinity Lx150-200 3” Minimum 5” [127 mm] 2-7/8” [73 mm]

Trinity Lx300-600 4” Minimum 4” [100 mm] 1-7/8” [48 mm]

Trinity Lx700-800 6” Minimum 6” [152 mm] 2-1/2” [63 mm]

Vent/Air-Intake Pipe Material

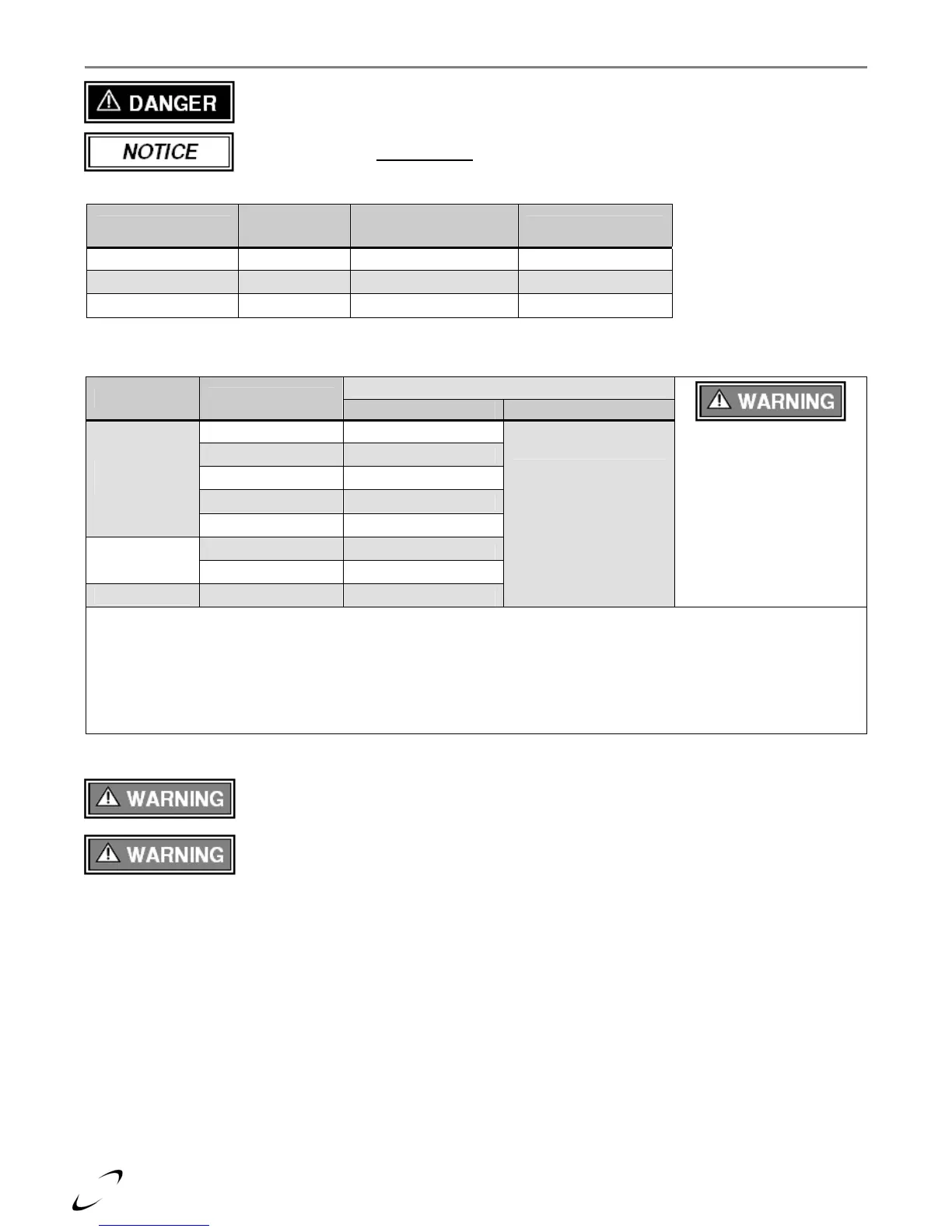

Table 4-3 Acceptable Vent and Air-Intake Pipe Material

Installation Standards

Items

1

Materials

2, 3

United States

Canada

4

PVC - DWV ANSI/ASTM D2265

PVC Schedule 40 ANSI/ASTM D1785

CPVC Schedule 40 ANSI/ASTM F441

AL29-4C UL-1738

Vent Piping

and Fittings

Polypropylene (PP) n/a

PVC ANSI/ASTM D2564

Pipe Cement

CPVC ANSI/ASTM F493

Primers

PVC / CPVC ANSI/ASTM F656

All venting material in

Canada must be

ULC S636 approved.

See Note 4 below for

appropriate temperature

applications.

All Vent and Air-Intake

materials installed on gas

fired appliances in CAN/US

must meet the Standards

listed in Table 4-3. Failure

to comply could result in

fire, serious injury or death.

Notes:

1

Refer to Table 4-4 for Allowable Vent and Air-Intake Pipe Sizes and Lengths.

2

PVC venting (exhaust and air-intake) is not permitted within the Closet/alcove of a Closet/alcove installation.

3

The Air-Intake does not require high temperature pipe material. Check applicable local codes for acceptable materials.

4

ULC S636 PVC is approved for flue gas temperatures up to 149

o

F (65

o

C) and must only be used for low temperature

applications. High temperature applications requiring appliance supply water temperatures greater than 140

o

F (60

o

C)

must use ULC S636 CPVC, PP or AL29-4C.

Mandatory Pre-commissioning Procedure for Plastic Venting

Do not apply power to the appliance prior to Step 4 in the Mandatory Pre-commissioning

Procedure for Plastic Venting.

Spark Igniter Cable - Maintain a minimum 2” separation between spark igniter circuit and

conductors. Failure to follow instructions may result in component failure, injury or death.

1) Working with the power turned off to the appliance, completely install the vent and air intake system,

securely cementing joints together. If possible, allow primers/cements to cure for 8 hours before firing the

burner. If curing time is less than 8 hours, proceed with Steps 2 through 6.

2) Maintain the appliance gas supply shut-off valve in the off position.

3) Disconnect electrical leads to the Hot Surface or Spark Igniter. Ensure the cables are placed in a fashion

where they will not arc to ground or other conductor. Refer to warning regarding Spark Igniter Cable.

4) Turn power on to the appliance and apply a heat demand.

5) Allow for 3 complete trials for ignition, consisting of pre and post purge of the combustion blower, until an

ignition lockout occurs. Repeat the process two more times (i.e. 9 complete ignition sequences in total).

6) Turn power off and reconnect the electrical leads to the Igniter.

Loading...

Loading...