103

TRX Series II - Installation - Startup - Maintenance Instructions

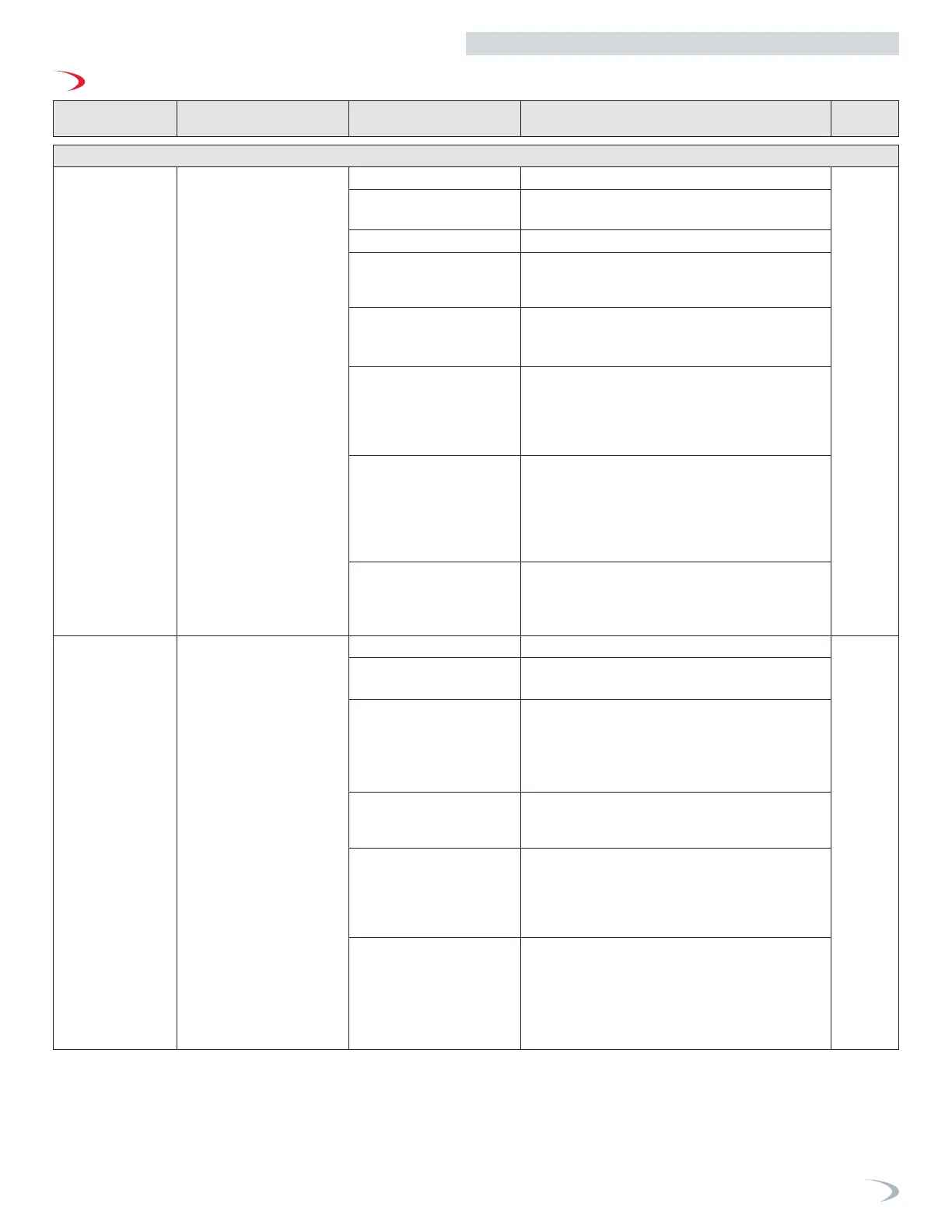

B. Boiler Error Codes

CH Circuit

1 01*

101

Outlet temperature

exceeded 210F

Reset the error by tapping the reset button

Blocking

(Manual

Reset)

Air in the system

Ensure boiler is free of air and pressurized to at least

20PSI

Return filter plugged Ensure return filter in the boiler (if equipped) is clear

Failed internal circulator/

internal circulator not

powered

Verify that the internal pump is operating properly

(blue light on solid). Verify the pump has 120VAC

when the heating or hot water call is active

Plugged plate heat

exchanger(combi only)/

indirect hot water tank

If problem occurs during hot water demands only,

check the plate exchanger, combi boilers, or indirect

hot water tank and plumbing for blockages.

Improper piping or boiler

commissioning

If not using the DHW connection ensure the diverting

valve is moving freely and is locked in the heating

position (upper position). See diverting valve stuck

ensure the piping matches the instructions in the

installation manual for that specific model.

Damaged/ Malfunctioning

temperature sensor

Swap the inlet and outlet sensors and verify that the

sensors read correctly in both positions. If the sensors

differ by more than 5F, replace the sensors, check for

water damage or corrosion on sensors. Compare the

resistance of the sensor to the temperature resistance

chart.

Safety circuit interrupted

Check the loop of black wire, connector 26, on PCB

(cn26). If a LWCO or other safety device is wired into

the jumper, check the device for proper operation.

Reseat the electrical connector and reset the error.

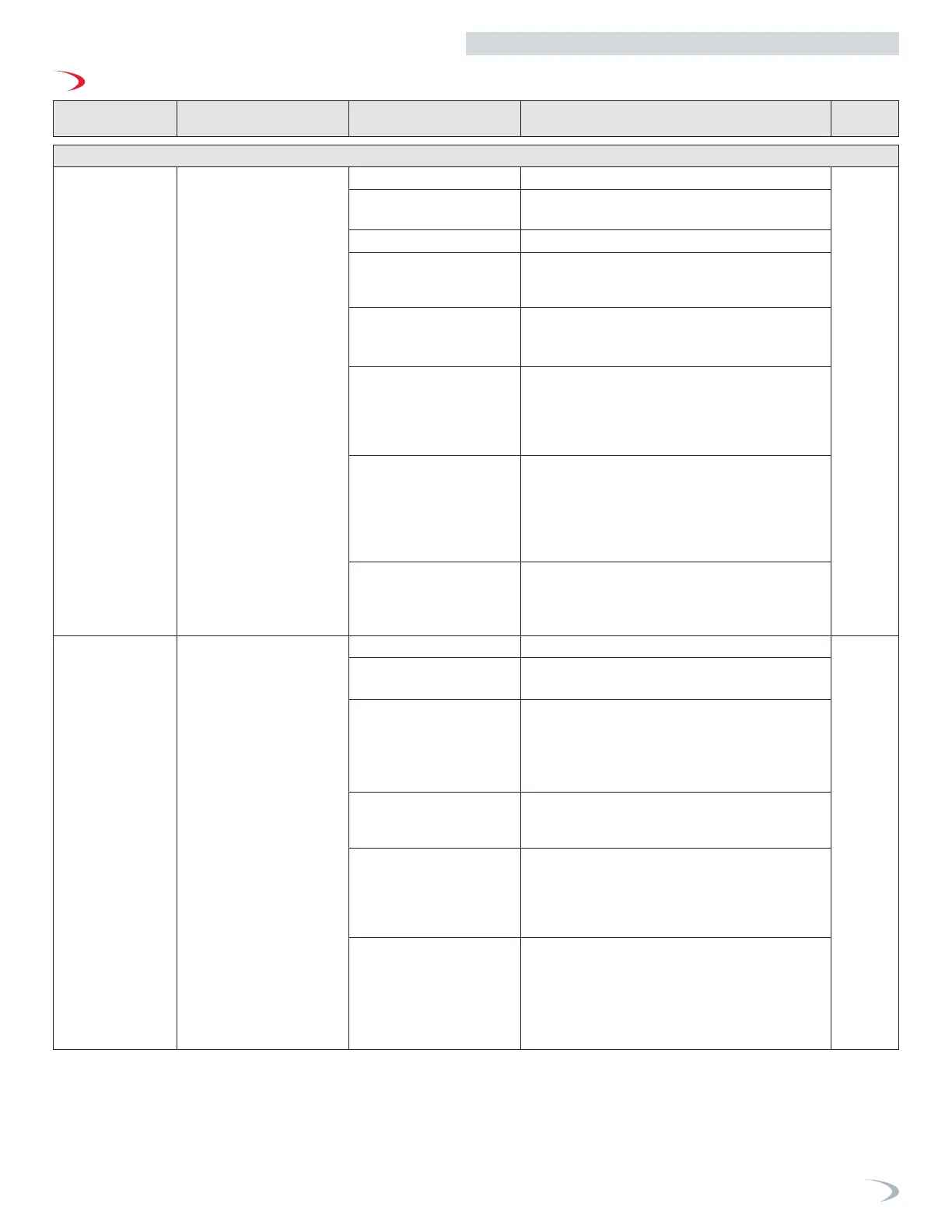

1 03*

103

Supply temperature rising

faster than 12.6 degrees per

second three times in a row.

Reset the error by tapping the reset button

Blocking

(Manual

Reset)

Air in the system

Ensure boiler is free of air and pressurized to at least

20PSI

Failed internal circulator/

internal circulator not

powered

If the problem occurs during heating and hot

water demands, ensure return filter in the boiler (if

equipped) is clear, and the internal pump is operating

properly (blue light on solid). Verify the pump has

120VAC with the heating or hot water call is active.

Plugged plate heat

exchanger(combi only)/

indirect hot water tank

If problem occurs during hot water demands only,

check the plate exchanger (combi boilers only) or

indirect hot water tank and plumbing for a blockage.

Improper piping or boiler

commissioning

If not using the DHW connection ensure the diverting

valve is moving freely and is locked in the heating

position (upper position) See diverting valve stuck,

ensure the piping matches the instructions in the

installation manual for that specific model.

Damaged/ Malfunctioning

temperature sensor

Swap the inlet and outlet sensors and verify that the

sensors read correctly in both positions. If the sensors

differ by more than 5F, replace the sensors, check for

water damage or corrosion on sensors. Compare the

resistance of the sensor to the temperature resistance

chart.

Part 13 - Troubleshooting

Display Error code Error Description

Possible cause

Possible Remedies

Error

Loading...

Loading...