93

TRX Series II - Installation - Startup - Maintenance Instructions

WARNING

WARNING

WARNING

CAUTION

CAUTION

Ensure the boiler is full of water before firing the burner. Failure

to do so will damage the boiler. Such damage IS NOT covered

by warranty, and could result in property damage, severe

personal injury, or death.

Ensure the boiler is full of water before firing the burner. Failure

to do so will damage the boiler. Such damage IS NOT covered

by warranty, and could result in property damage, severe

personal injury, or death.

Eliminate all system leaks. Continual fresh make-up water will

reduce boiler life. Minerals can build up in the heat exchanger,

reducing heat transfer, overheating the heat exchanger and

causing heat exchanger failure.

Check if the condensate trap contains water. If not, it must be

refilled. Open the manual air vent on the main exchanger until

completely filled. Check the system pressure on the pressure

gauge again.

It is highly recommended to carefully follow the glycol

manufacturer’s recommended concentrations, expansion

requirements, and maintenance recommendations (pH

additive breakdown, inhibitor reduction, etc.) You must

carefully calculate the additional friction loss in the system as

well as the reduction in heat transfer coefficients.

Connect the condensate discharge pipe before filling and

purging the heating circuit.

It is important to purge the system of air to avoid damage to

the boiler.

6. Anti-freeze solutions expand more than water. For example: A 50%

by volume solution expands 4.8% in volume for a temperature

increase from 32 - 80

o

F, while water expands 3% over the same

temperature rise. Allowances must be made in system design for

expansion.

7. A 30% mixture of glycol will result in a BTU output loss of 15% with

a 5% increase in head against the system circulator.

8. A 50% mixture of glycol will result in a BTU output loss of 30% with

a 50% increase in head against the system circulator.

NOTE: BTU losses apply to both CH and DHW.

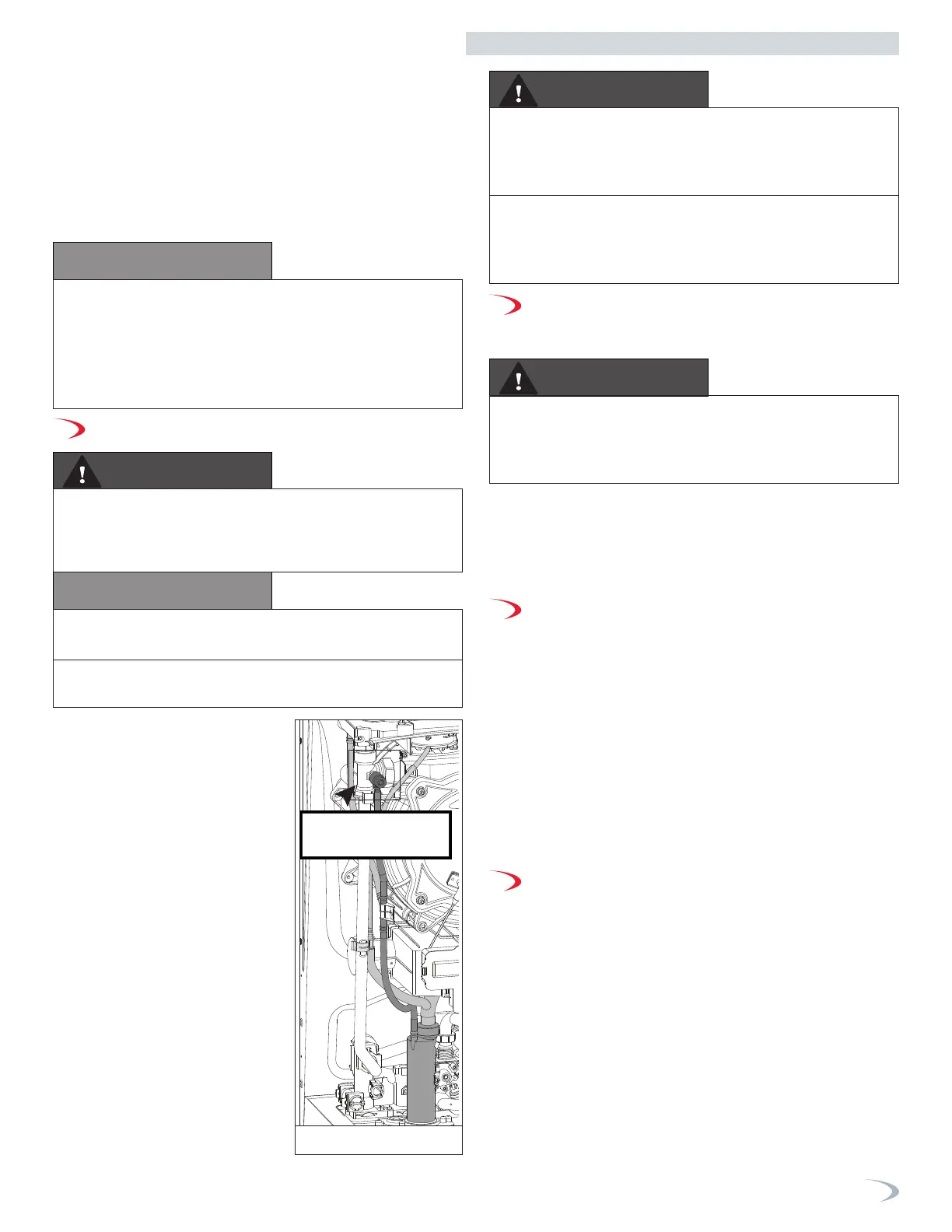

D. System Water Fill, Purge, and Test

The boiler and heating system must

be thoroughly purged of air during

the initial installation or system

maintenance. Proceed as follows to

purge the boiler and heating system:

1. Open the manual air vent positioned

on the side of the primary exchanger.

The valve is already connected

to a discharge hose routed to the

condensate trap.

2. Lift the cap on the automatic air

release valve on the pump. Leave

open permanently.

3. Gradually open the main water valve

until water flows. Do not open fully.

4. Thoroughly purge each zone starting

with the lowest point and close them

only when clear water free of air is

visible.

5. Close the manual air vent when clear

water free of air is visible.

6. Continue filling the system until at

least 12 psi registers on the pressure

gauge.

Figure 102 - Manual Air

Vent Position

F. Check Thermostat Circuit(s)

1. Disconnect the two external wires connected to the boiler

thermostat terminals TT1/TT2 (low voltage terminal strip).

2. Connect a voltmeter across these two incoming wires with power

supplied to the thermostat circuits. Close each thermostat, zone

valve and relay in the external circuit one at a time and check the

voltmeter reading across the incoming wires.

3. There should NEVER be a voltage reading.

4. If a voltage reading does occur under any condition, check and

correct the external wiring. (This is a common problem when using

3-wire zone valves.)

5. Once the external thermostat circuit wiring is checked and

corrected if necessary, reconnect the external thermostat circuit

wires to the boiler low voltage terminal strip. Allow the boiler to

cycle.

E. Purge Air from DHW System

1. Make sure the CH and DHW lines are open and full of water. Turn on

all electric power to boiler.

2. Open hot water faucets in the DHW system. Start with the faucets

nearest the boiler.

3. Keep faucets open until water runs freely and all air is purged. Then

move on to faucets further away from the boiler in the system.

4. When water flows freely from all hot water faucets, DHW purging is

complete.

G. Condensate Removal

1. The boiler is a high efficiency condensing appliance. Therefore, the

unit has a condensate drain. Condensate fluid is nothing more than

water vapor, derived from combustion products, similar to that

produced by an automobile when it is initially started.

Condensation is slightly acidic (typically with a pH of 3 to 5)

and must be piped with the correct materials. Never pipe the

condensate using steel, copper, brass or other materials that will

be subject to corrosion. Plastic PVC or CPVC pipe are the only

approved materials.

A condensate neutralizer, if required by local authorities, can be

made up of lime crystals, marble or phosphate chips that will

neutralize the condensate.

2. The boiler is equipped with a barbed outlet fitting, to which the

supplied hose must be installed and routed to a local drain. It is

very important that the condensate line is sloped downward away

from the boiler to a suitable indoor drain.

Boiler Manual Air

Vent

Part 10 - Start-Up Preparation

Loading...

Loading...