5 - 12 en-938821/2

5.2.1.2 Part Origin Shift Introduction

By bringing the spindle into contact with the part, this procedure enables the CNC to measure the part origin shifts

(DAT1) directly.

When a setting piece is inserted between the spindle and the part, this method can still be used, but the part origin

shift values must be modified via the keyboard to take into account the dimensions of the setting piece.

The procedure described below is only one of the possible methods of entering the part origin shift values.

Requirements

Homing procedure performed (See 5.1.2).

No mode being executed.

Actions

For each axis:

Manually bring the spindle datum into contact with the origin surface of the

reference part.

Select the origin setting mode (See 5.2.1.1).

Enter "*[axis name]". ☞

Transfer of the spindle datum measurement dimension of the corresponding axis to DAT1 which is then displayed on

screen.

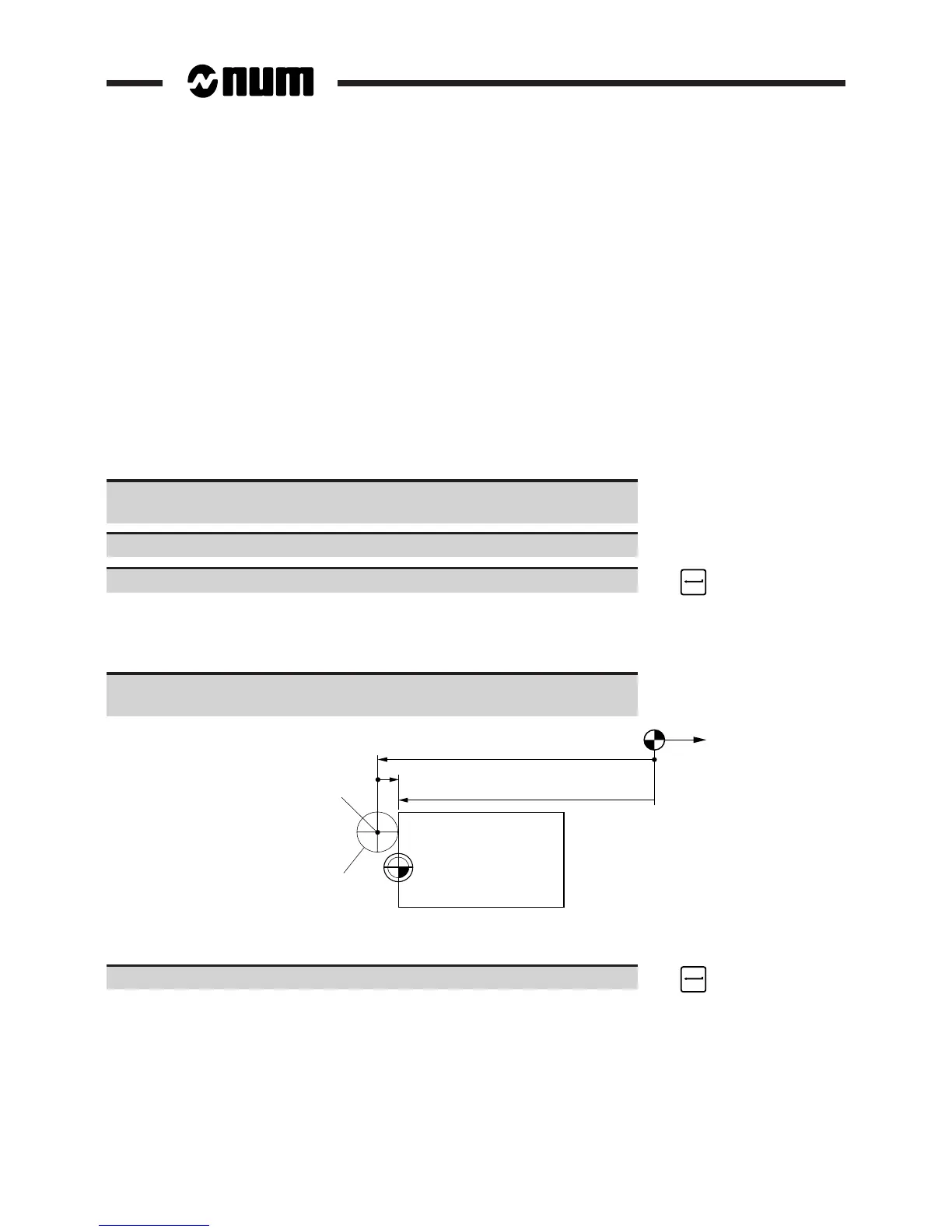

If using a test bar for example:

Calculate the real value of DAT1 taking into account the dimensions of the

test bar (See diagram).

Op

Real DAT1

Op/spindle datum shift

OM

Test bar Ø 100

Displayed DAT1

Spindle

datum

real DAT1 = displayed DAT1 + Op/spindle datum shift (algebraic value)

Enter "[axis name][real DAT1]". ☞

The real DAT1 is displayed.

Loading...

Loading...