Operating Instruction and Documentation

2.30 SPL

- 23 -

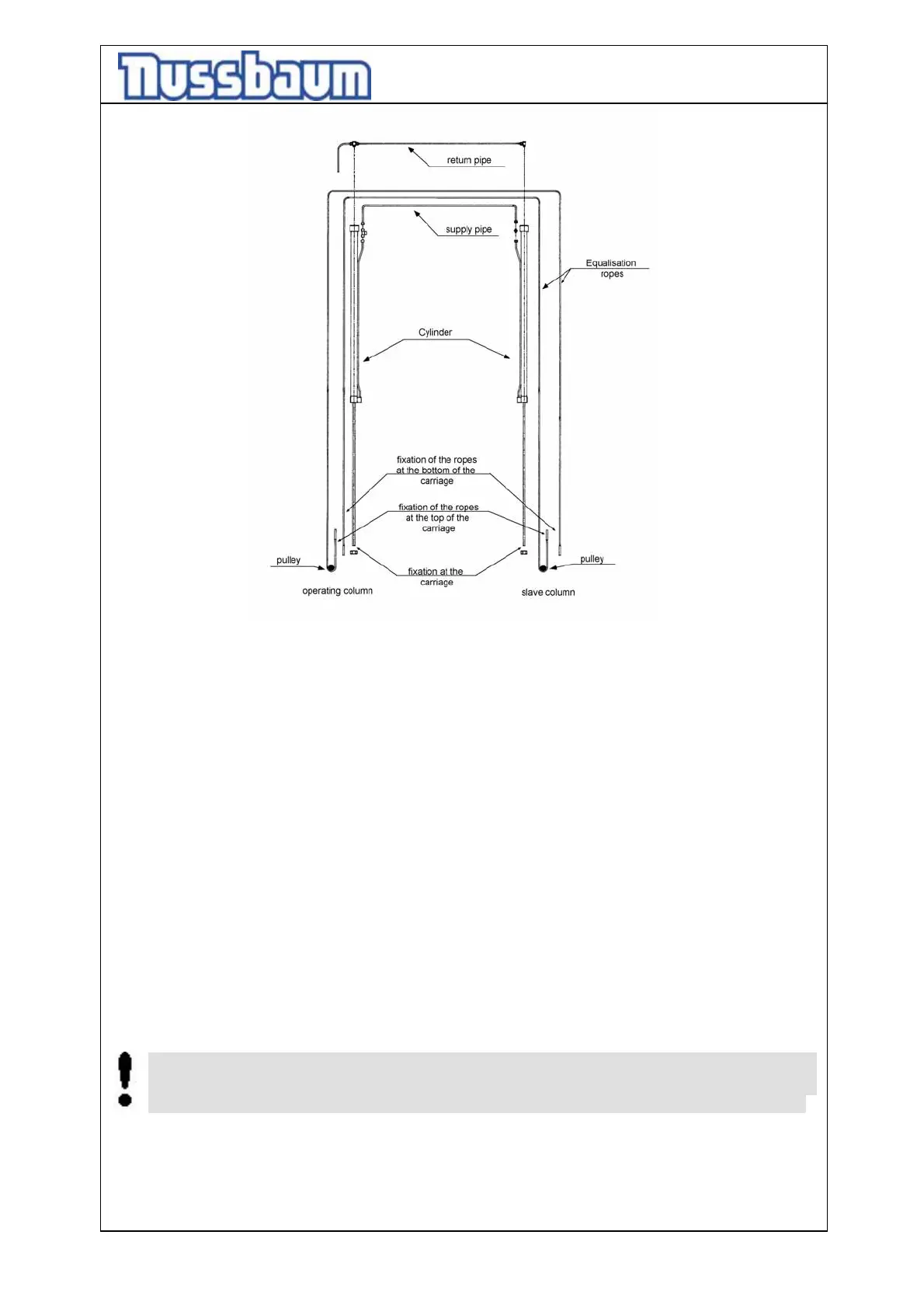

pic 5:

course of the ropes

• Check the positions of the columns again.

• Bore holes to fix the dowels through the borings of the base plates. Clean holes with

pressure air. Put in safety dowels with washers in borings. The manufacturer

demands LIEBIG safety dowels type B 20 or equal dowels of another manufacturer

but pay-attention their regulation.

• Before doweling check concrete floor with quality B 25 if the concrete floor goes to the top

edge of the floor. In this case the dowels have to be chosen according to

picture 6. If the ground is covered with floor tiles, the dowels have to be chosen

according to picture 7.

• Check line-up of the columns and look if they are vertical. If they aren’t vertical

correct with suitable bases (thin metal sheets). In case of vibration of the columns,

position the suitable bases (thin metal sheet) under the middle of the base plate, too.

• Tighten the Dowels with a dynamometric key (according to the demand of the

manufacturer). Pay attention to the regulation of the dowel manufacturer.

Each masonry bolt must be tightened to the specified torque. Otherwise the normal

function of the lift can not be guaranteed.

Observe the regulations of other masonry-bolt manufacturers.

• Mount optional safety device (rope).

• Connect the power supply. The cable entry is at the bottom side of the operation column

(standard).

• Fill oil-tank with oil: viscosity 32 cst, hold-up: approx. 10 litre. Remove the cover of the

Loading...

Loading...