Setting Belt Oscillation

! WARNING

Setting belt oscillation may require operator

to have machine hooked to electrical and air

power while having doors open. Use

extreme caution! Failure to comply may

cause serious injury!

Now that the belt is tracking properly it is time to

set the oscillation. Follow the steps listed below.

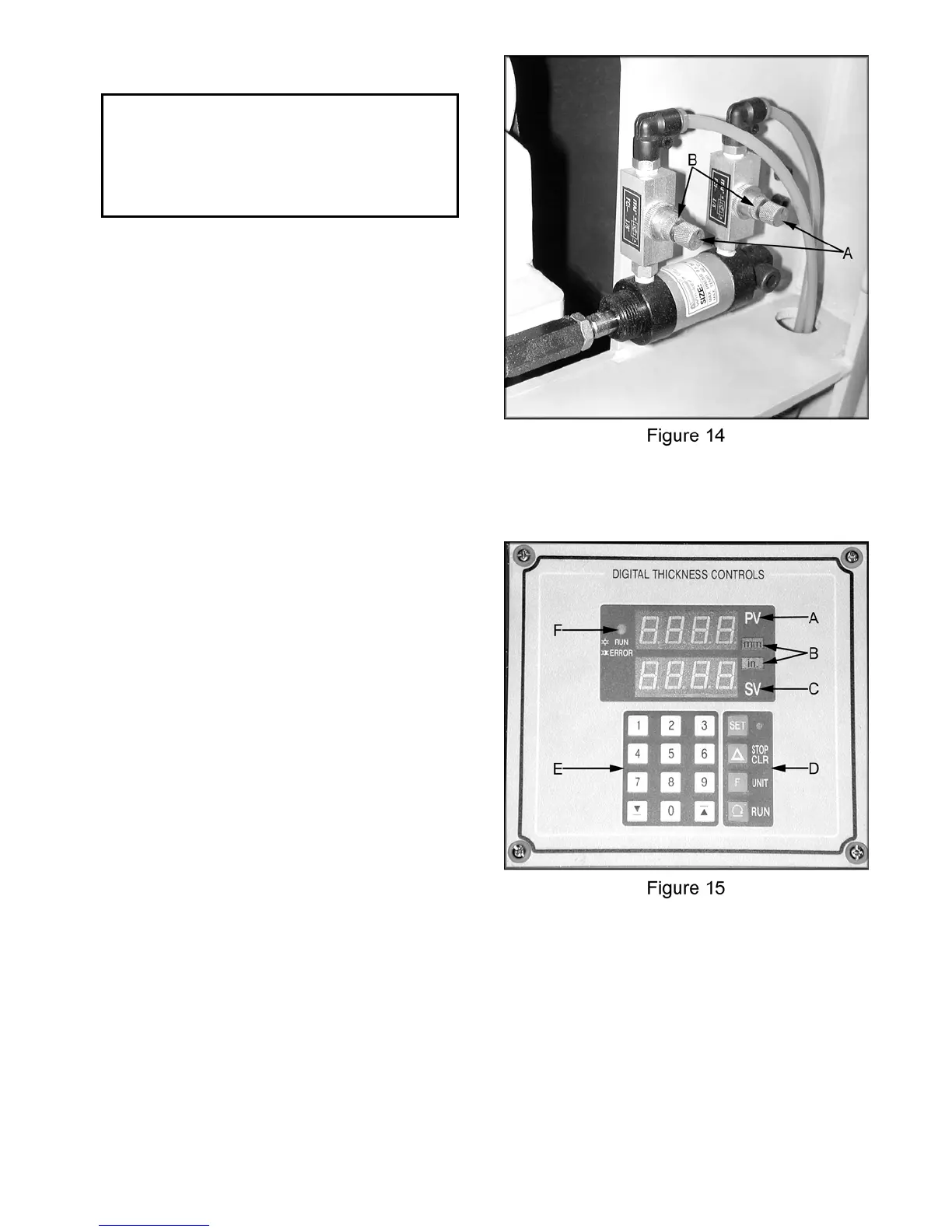

1. Start by opening both valves (A, Figure 14)

approximately a 1/4 turn.

2. If the belt is oscillating too quickly, close

each valve by approximately 1/16 turn. If

the belt is oscillating too slowly, open each

valve by approximately 1/16 turn.

3. Once the belt is oscillating with the correct

speed (about one complete cycle every

second), lock the valves in place with the

lock rings (B, Figure 14).

Digital Controller

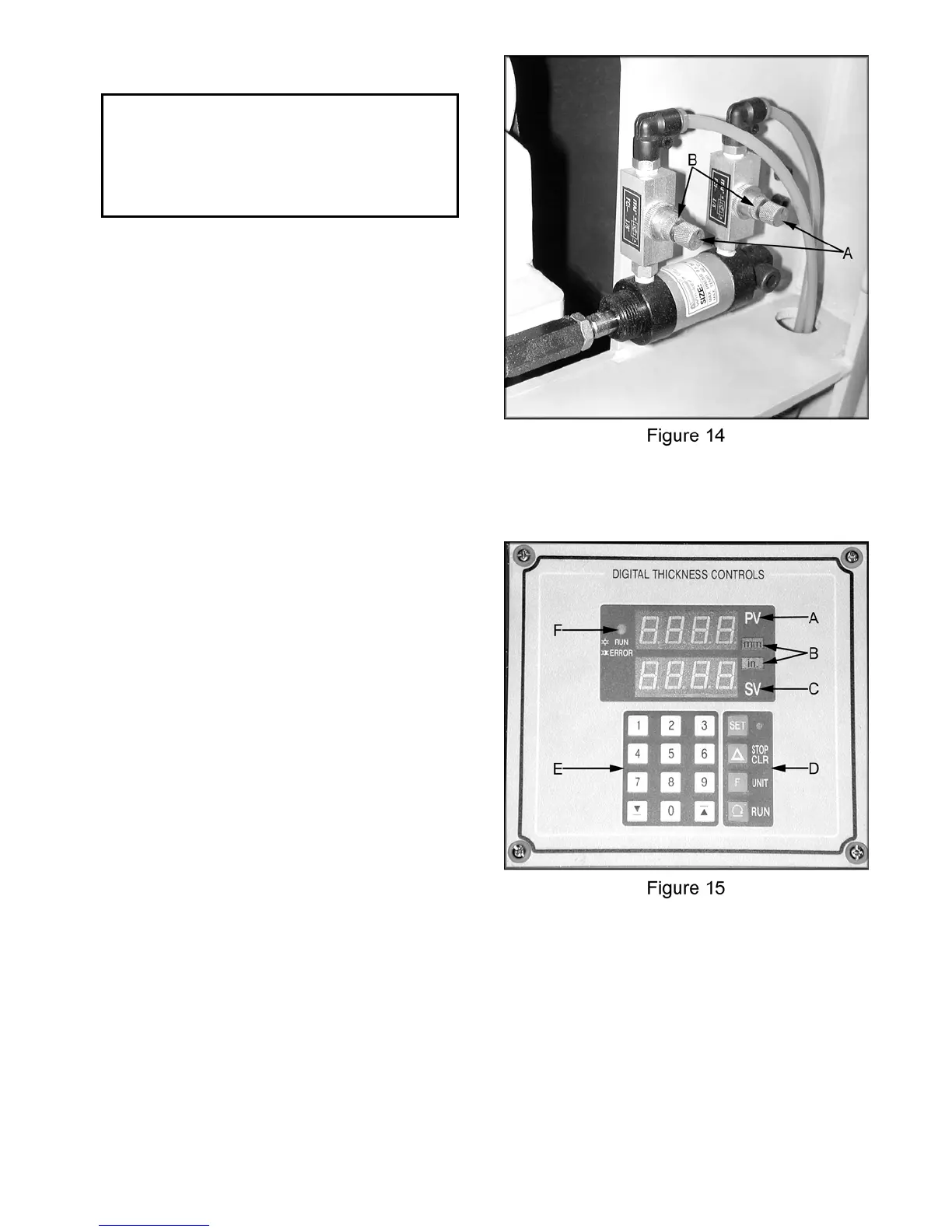

A. This LED readout displays the current

thickness setting of the machine.

B. The digital thickness controls are capable of

operating and displaying in either inches, or

millimeters.

C. This LED readout displays the value input by

the operator on the keypad.

D. Four function buttons are available to the

user: SET, STOP/CLEAR, UNITS, and

RUN. The use of these buttons is detailed

in the following sections.

E. The keypad is used to input set values (the

operator’s desired thickness setting). The

up and down arrows can be used to move

the table up or down without keying in an

exact numerical thickness value.

F. This indicator light will illuminate a steady

yellow when the table is moving up or down.

This light will blink if there is an error of any

sort.

12

Loading...

Loading...