SUCTION PUMP KV--5

5

2 OPERATING PRECAUTIONS

2.1 Before use

D The unit must be used solely for its designed purpose, that is endoscopic aspiration and general medical or surgical

suction in a health care facility. This device is a ‘high vacuum, high flow’ device and is not intended for thoracic

drainage.

D Explosion hazard -- never install or use the KV--5 within the zone of risk of flammable gases.

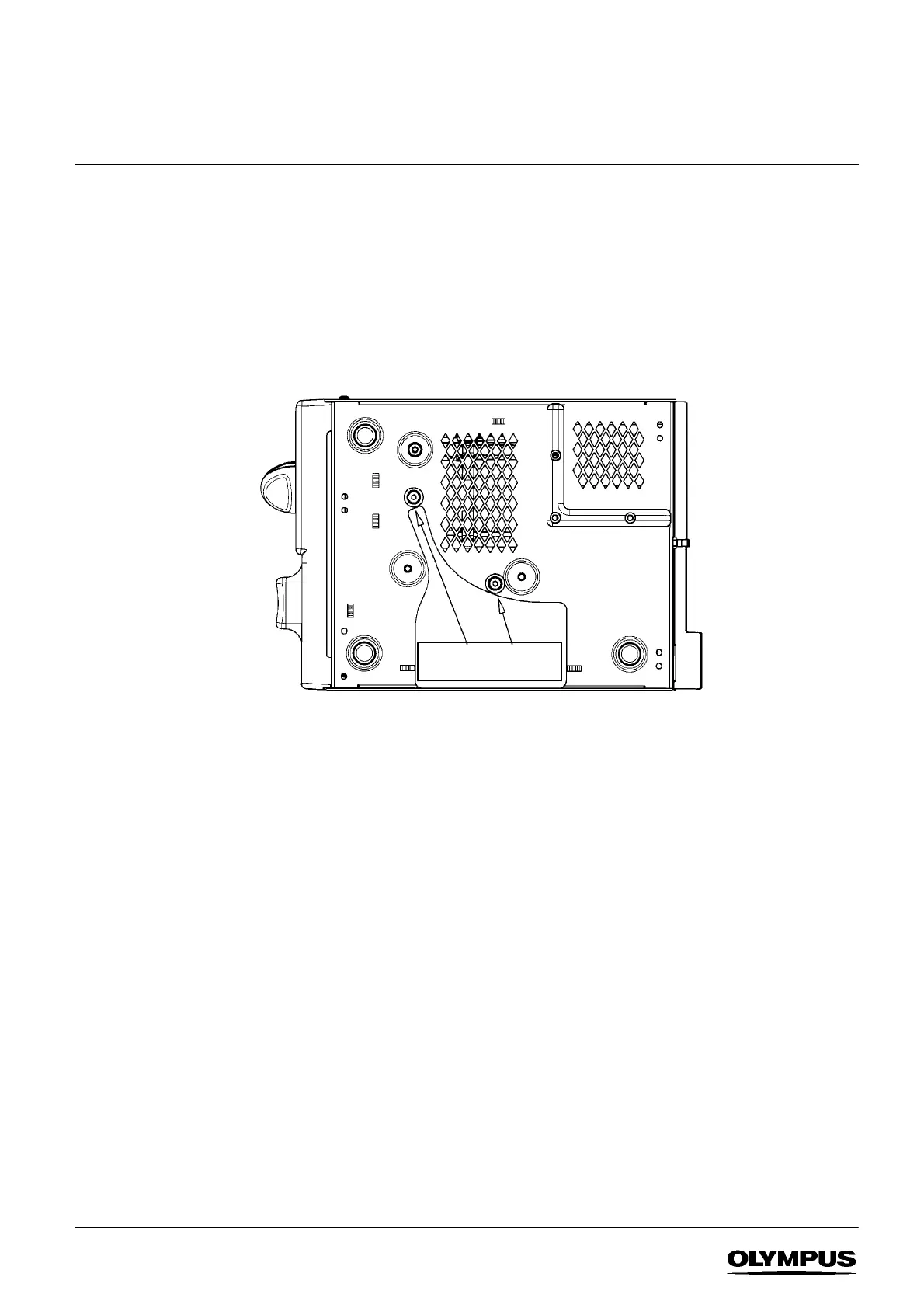

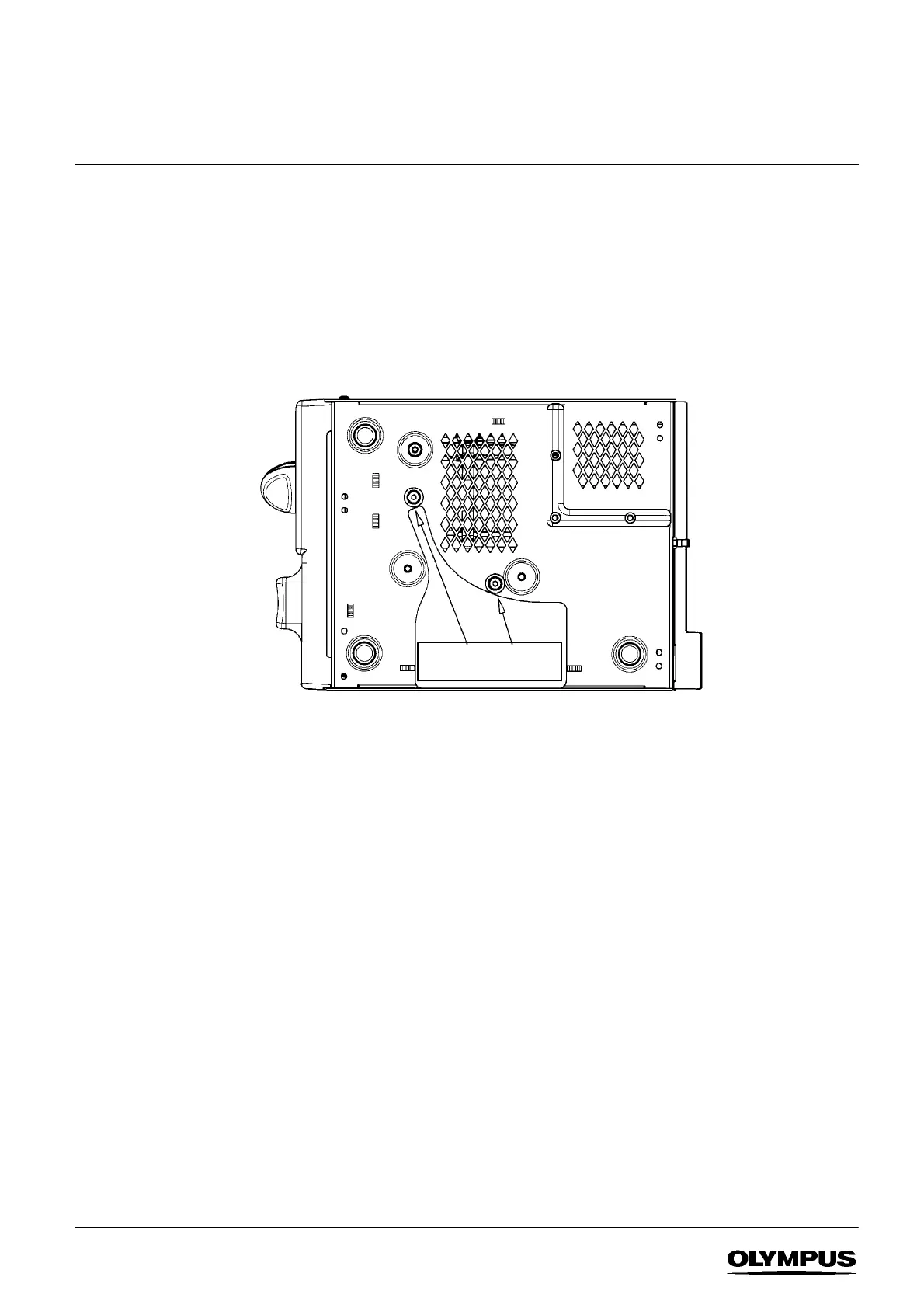

D The unit is fitted with two M6 transit screws to protect the pump during transportation. Before use, r emove both

screws with fibre washers using the 4mm A/F Allen key provided (Figure 2-1), then remove the label from the top of

the unit. Store these items safely as they must be refitted when transporting the unit.

FIGURE 2-1

CAUTION: REMOVE TRANSIT

SCREWS BEFORE USE. REPLACE

BEFORE TRANSPORTATION.

D Excessive frothing in the suction jar during use may inhibit operation of the fluid cut--off mechanism -- use a

proprietary anti--foam agent as necessary to minimise frothing.

D The electrical installation of the room where the unit is to be used must comply with local or national regulations.

D The KV-5 is not intended to be used when positioned on inclined sur faces as the suction jar fluid cut--off mechanism

may not function correctly.

D The unit is only to be used by suitably qualified personnel in accordance with these instructions.

D Replace the microbial filter daily or when contaminated.

D Do not use anti-static tubing to connect the endoscope to the suction pump as patient safety may be compromised.

D The suction jar must never be used ‘free standing’ on the workstation or any surface. The 1 litre suction jar simply

slides into the bracket provided on the front panel of the unit as shown on page 2, the 2 litre suction jar should be

secured to workstation using the suction jar br acket.

D Periodically inspect the suction jar for obvious signs of wear/damage and replace if necessary.

D If the suction jar is dropped, it must be thoroughly inspected to ensure there are no cracks and tested to ensure the

lid is sealing correctly. If damage or a leak is evident, discard the suction jar and replace.

D When a suction jar is attached to a workstation using the optional suction jar br acket, remove the suction jar before

manoeuvring the workstation.

Loading...

Loading...