Installation on 3/4” Copper Pipe:

5. Place the lock nuts on the pipe, small end first. Follow the lock

nuts with the brass compression sleeves (one for each cut pipe

end). Slide each brass compression sleeve up 1/4” from the cut

end of the pipe (see Figure 3).

6. Thread the brass compression fittings into the ports in the hous-

ing. Be sure that the smaller 3/4“ NPT end of the fitting goes into

the port. Tighten the compression fittings with the 1-1/4”

wrench until they are snug. DO NOT OVERTIGHTEN.

7. Place the filter (with its fittings) in position on the pipe. Be sure

that the port marked “IN” is on the side toward the water meter

so that the flow enters the filter through this port.

8. Insert the copper pipe into the inlet, making sure that the copper

pipe bottoms out inside the filter head. Tighten the left-hand lock

nut securely with the wrench. Hold the fitting with a wrench to

prevent overtightening it in the housing.

9. Repeat Step 8 with the outlet compression fitting, sleeve, and

nut. Skip to Step 10 under “All Installations”.

Installation on Galvanized Pipe:

5. Thread the cut pipe ends and clean all traces of cutting oil, rust,

hardened pipe compound, etc., from all threads that will be

attached to the unit. Clean the pipe threads with paint thinner or

solvent (NOT gasoline) and dry them with a clean rag; remove all

chips; polish and deburr. Use only teflon tape (without adhesive

backing) on the pipe threads attached to this unit.

6. Apply teflon tape three turns around the threads of the pipe

coming from the water meter. Using the “IN” port, hand screw

the filter onto the water pipe until it is tight. Removing the tank

will make this easier. DO NOT OVERTIGHTEN.

7. Wrap three turns of teflon tape around each end of the 2” nipple

and screw one end into the “OUT” port on the filter. Screw the

union onto the other end of the nipple.

8. Wrap the remaining pipe thread with teflon tape and screw the

other side of the union onto it until tight.

9. Assemble the union and tighten the large nut securely. Make sure

that the pipe ends align and that the union is clean for a water-

tight fit (no tape or compound on the union-half threads). See

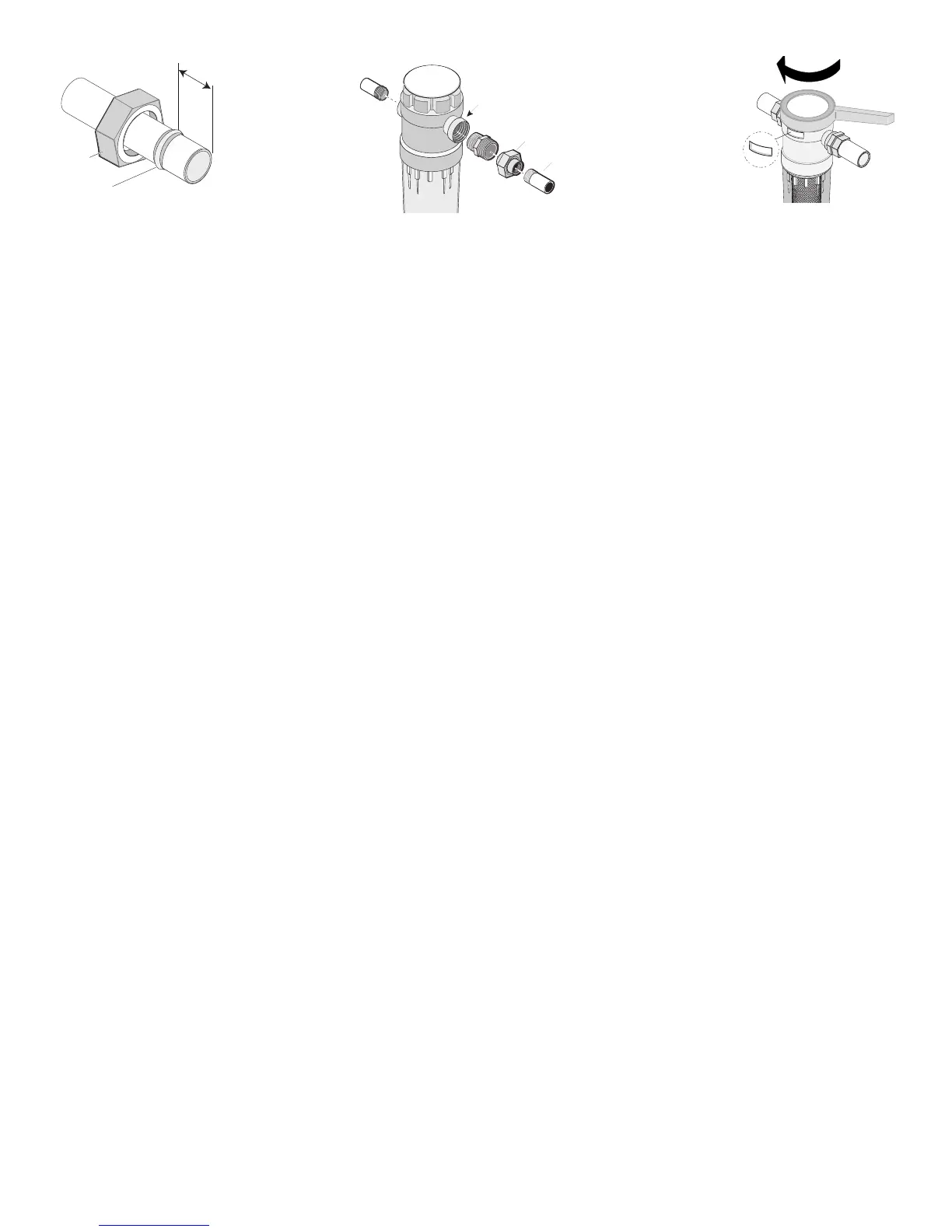

Figure 4.

All Installations:

10.Install the filter cartridge in the Cartridge Tank.

11.To avoid flooding and water damage, make sure that the

O-Ring between the housing and the tank is in good condition

and pr

operly seated in its gr

oove when r

eassembling the unit.

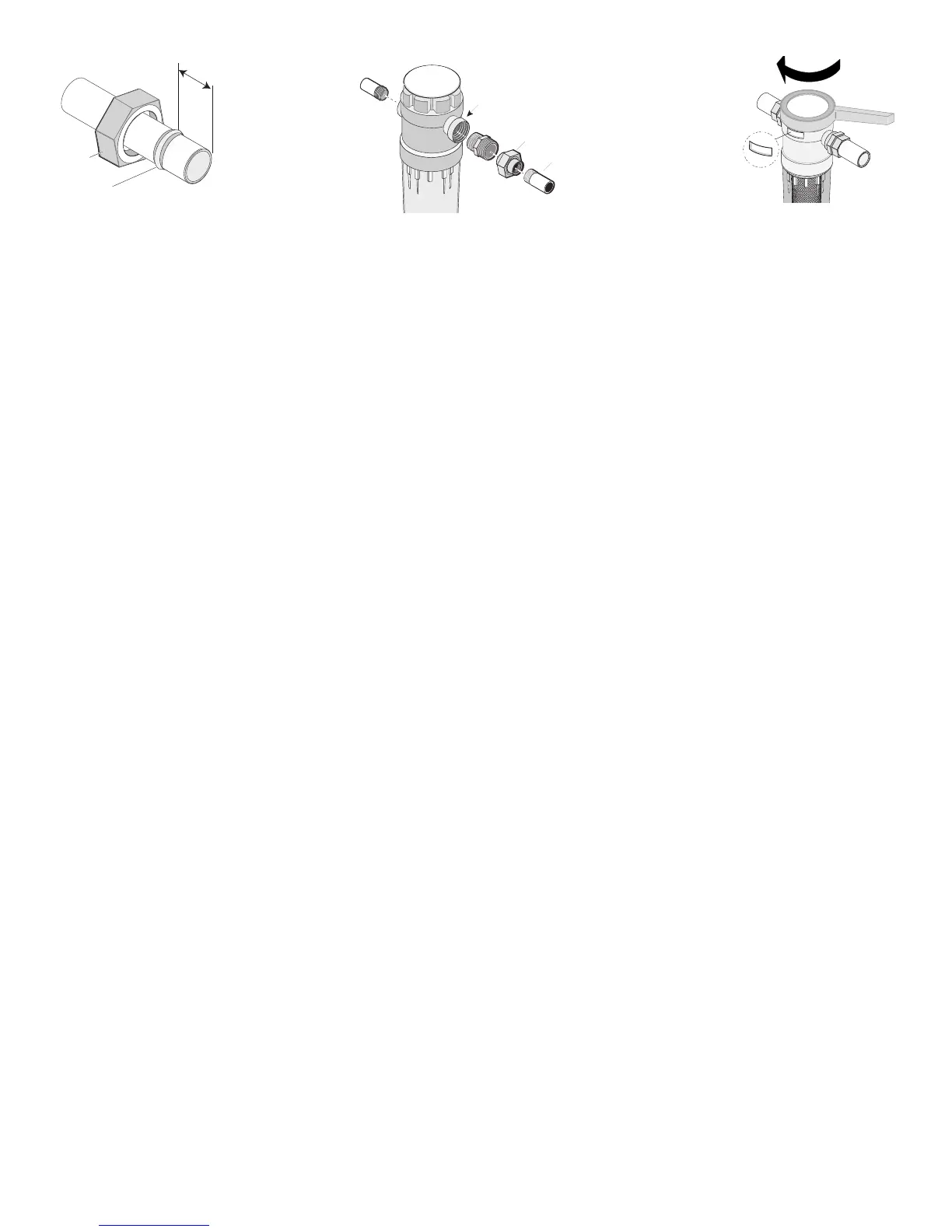

12.The filter is now ready to test. Turn the filter top (using the blue

wrench supplied with the filter) clockwise to “OFF”. Slowly open

the main water supply valve and check for leaks. Turn the filter

top (again using the wrench) from “OFF” to “FILTER”. If any fit-

tings or joints leak, tighten slowly until the dripping stops.

13.Open the faucet and flush the filter for at least 10 minutes after

installation to r

emove the trapped air

. Flush the unit for at least

10 seconds ever

y time you use water for drinking or cooking,

especially if the water tap is not used daily.

WHEN TO CHANGE THE CARTRIDGE

The cartridge’s life depends on the water volume used and the

substances in the water. Normally the cartridge should be changed

at intervals of ninety days or less. Replace it sooner if the water

ressure at the faucet begins to drop noticeably or if you notice

changes in the taste, color, or flow of the filtered water.

NOTICE: Certain types of harmless bacteria will attack cellulose material.

Cartridges containing cellulose may seem to disintegrate, produce a

“sewer” or “rotten egg” odor, or form a black precipitate due to bac-

teria. If this happens, consult OMNIFILTER Customer Service for advice.

PROCEDURE FOR CARTRIDGE CHANGE

1. Place a pan under the unit to catch any spilled water and open

the nearest faucet.

2. Turn the filter top (using the blue wrench supplied with the

cartridge) clockwise about 45° to “OFF” (see Figure 5).

3. Fit the wrench onto the ribs of the tank and turn it slowly to the

left to release the pressure and loosen the tank.

4. Support the tank as you unscrew it. Pour out the water from the

tank and remove and discard the old cartridge. Wipe the inside

of the tank clean and dry with a soft cloth.

5. Insert a new cartridge into the tank, making sure that it seats

over the center post on the tank bottom.

6. Lubricate the tank O-ring with a good grade of silicone grease or

food-grade vegetable oil and check it for damage. If cut, abrad-

ed, or stretched, replace it with a new one.

7. Screw the filter tank back onto the filter housing. Hand-tighten

the tank. DO NOT OVER TIGHTEN.

8. Turn the top of the filter to “FILTER” with the filter wrench.

NOTICE: If the tank O-ring leaks after you have tightened the tank

with the wrench, DO NOT tighten it anymore. Instead, loosen it and

make sur

e that the car

tridge is seated over the center tube in the

head assembly (not pushing against it). After centering the cartridge,

r

e-tighten the tank and again check for leaks.

9. Open a faucet for about 10 minutes to allow any accumulation

of air, fines, etc., to flush out.

NOTICE: Use only genuine OMNIFILTER replacement cartridges for

best r

esults. Failur

e to use OMNIFIL

TER replacement cartridges will

void your warranty.

TO BYPASS THE FILTER

When watering lawns or doing other projects that don’t require fil-

tered water, the U25 Series B Complete Household Water Filter

System can be bypassed.

1. Turn the filter top (using the blue wrench supplied with the car-

tridge) clockwise about 45

°

to “BY

-P

ASS”. Refer to Figure 5 under

the “Pr

ocedure for Cartridge Change.” section.

2. To continue use of the Filter System, turn the filter top (using the

blue wrench supplied with the cartridge) counter-clockwise about

45° to “FILTER”.

Figure 4

Figure 5

3

Figure 3

1/4"

Compression

Slee

ve

Lockn

ut

Filter Ports

Water Flow

Pipe Union

Threaded,

Galvanized

Pipe End

2

”

pipe nipple

Loading...

Loading...