E3X-NH

E3X-NH

5

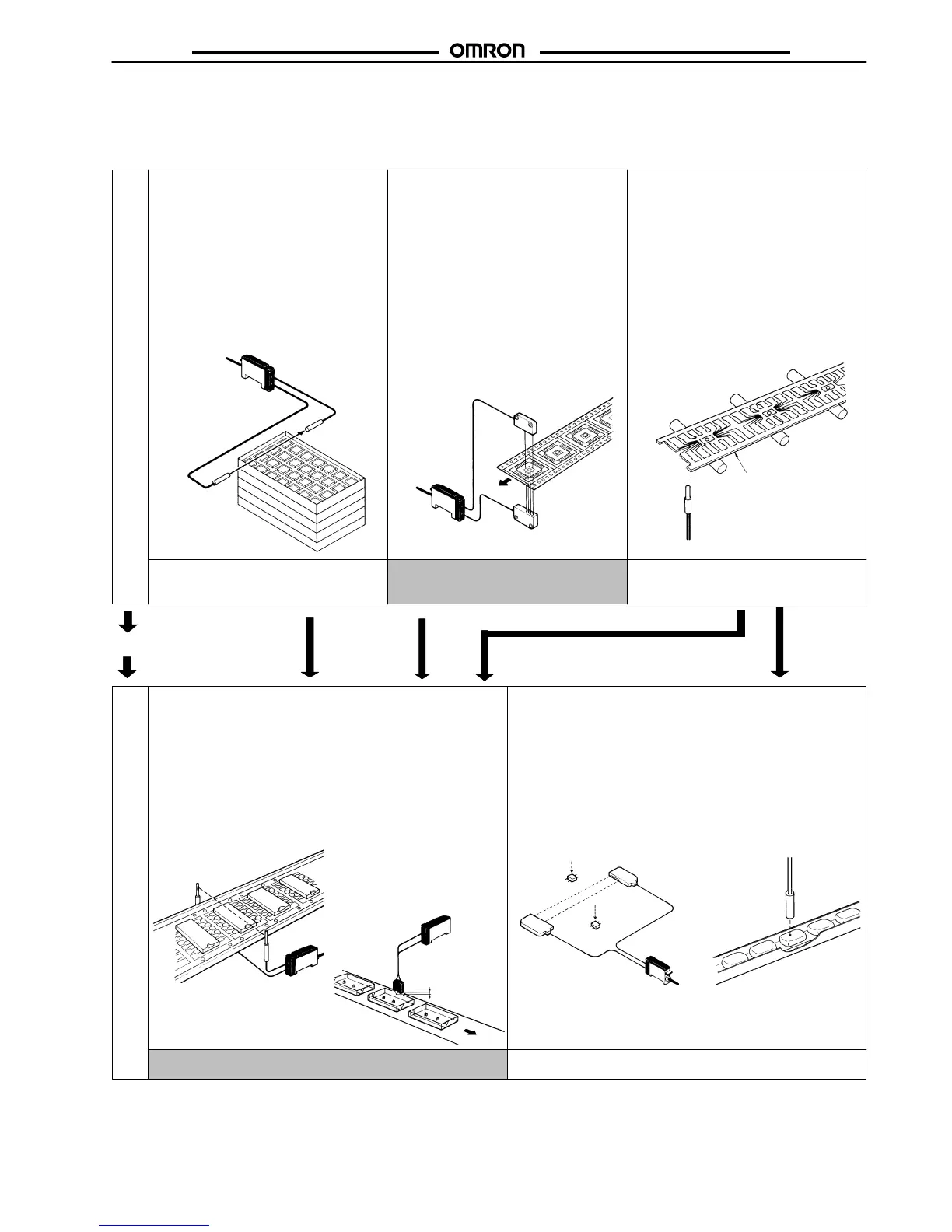

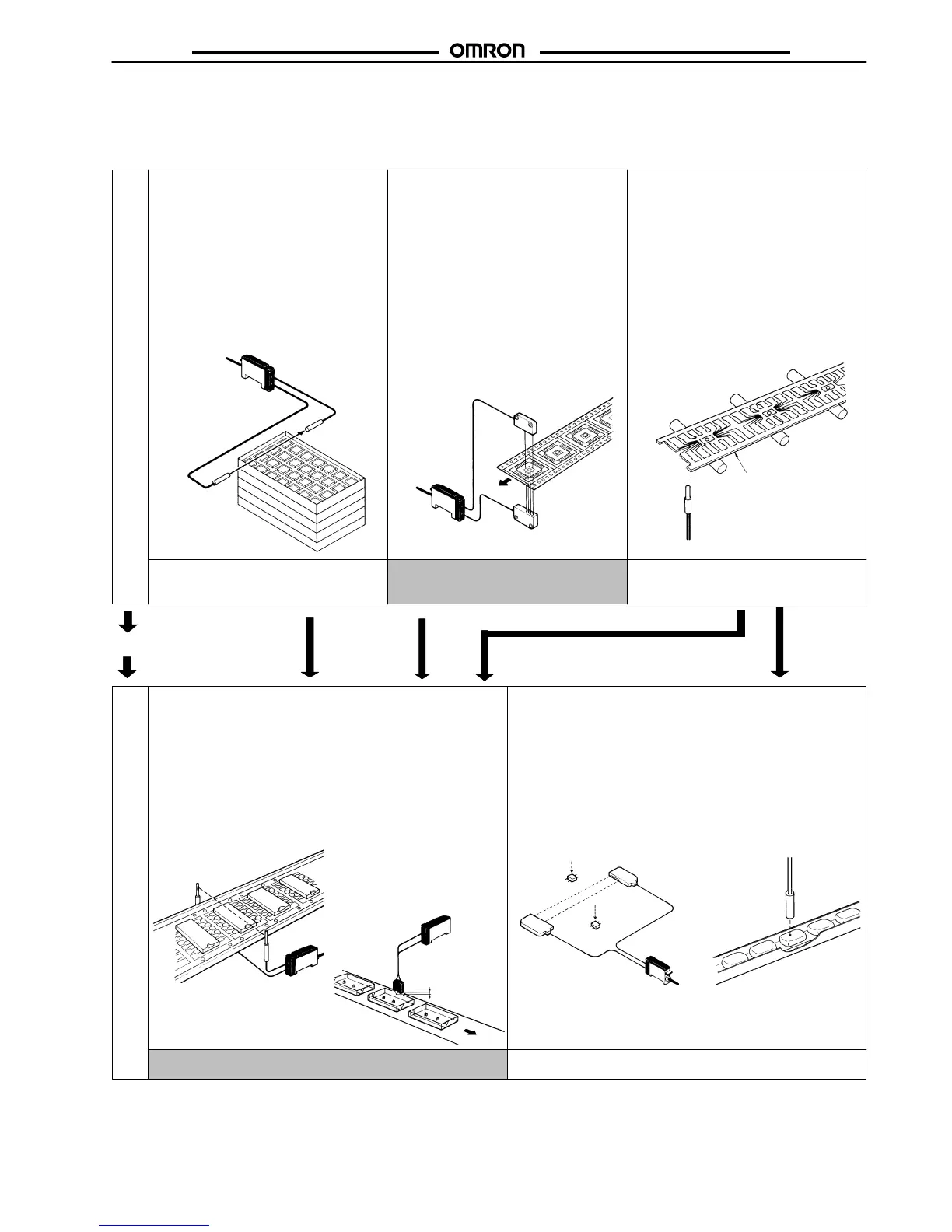

J SENSITIVITY SETTING AND ADJUSTMENT

Refer to the following to select the most suitable sensitivity setting method. We recommend that two-point teaching and manual-tuning be

tried first.

Using the Sensor at the

Maximum Sensitivity

Application Examples

Detection of a passing object with

through-beam fibers.

Checking IC T ray Arrangements

E3X-NH

Sensing Slight Differences

Application Examples

Detection of slight differences in

reflection.

Detection of translucent objects.

Detection of object surface irregu-

larities.

Color discrimination.

Detecting IC Chips on Film Sheet

E3X-NH

E32-T16P

Sensitivity Setting

Without Objects

Application Examples

Detection of minute passing ob-

jects.

Detection of lead wires.

High-precision positioning.

Detecting Lead Frame Position

E32-D32

Lead frame

Fine -tuning on Production Lines

Reason

Marginal sensitivity adjustment is required considering the

differences in targets.

For high-precision positioning of electronic parts.

Detecting

Lead Frame Rises

E3X-NH

Ideal Operation Under Frequently Changing

Environments

Reason

Dust sticking to the fiber tip.

Targets are slightly different from each other in color or

surface quality.

Detecting

Passing Chip Parts

E3X-NH

E32-T16P

Auto-tuning (Automatic Sensitivity Compensation)

Fine-tuning, if required.

E32-T24

Detecting

Cassette Tape Cases

Ensuring reliable detection

without being influenced by

the difference in color or

mark.

E3X-NH

E32-L25A

3.3 mm

Counting

Number Of Pills

Sensitivity Setting

Film sheet

Sensitivity Adjustment (Fine -tuning)

Maximum Sensitivity Setting One-point Teach ModeTwo-point Teach Mode

Manual-tuning (Fine Sensitivity Adjustment)

Loading...

Loading...