3-14

Sample Ladder Programming for Siemens PLC

This section provides an example of programming to monitor Safety Input terminal data of a

G9SP-series Controller from a Siemens Standard PLC.

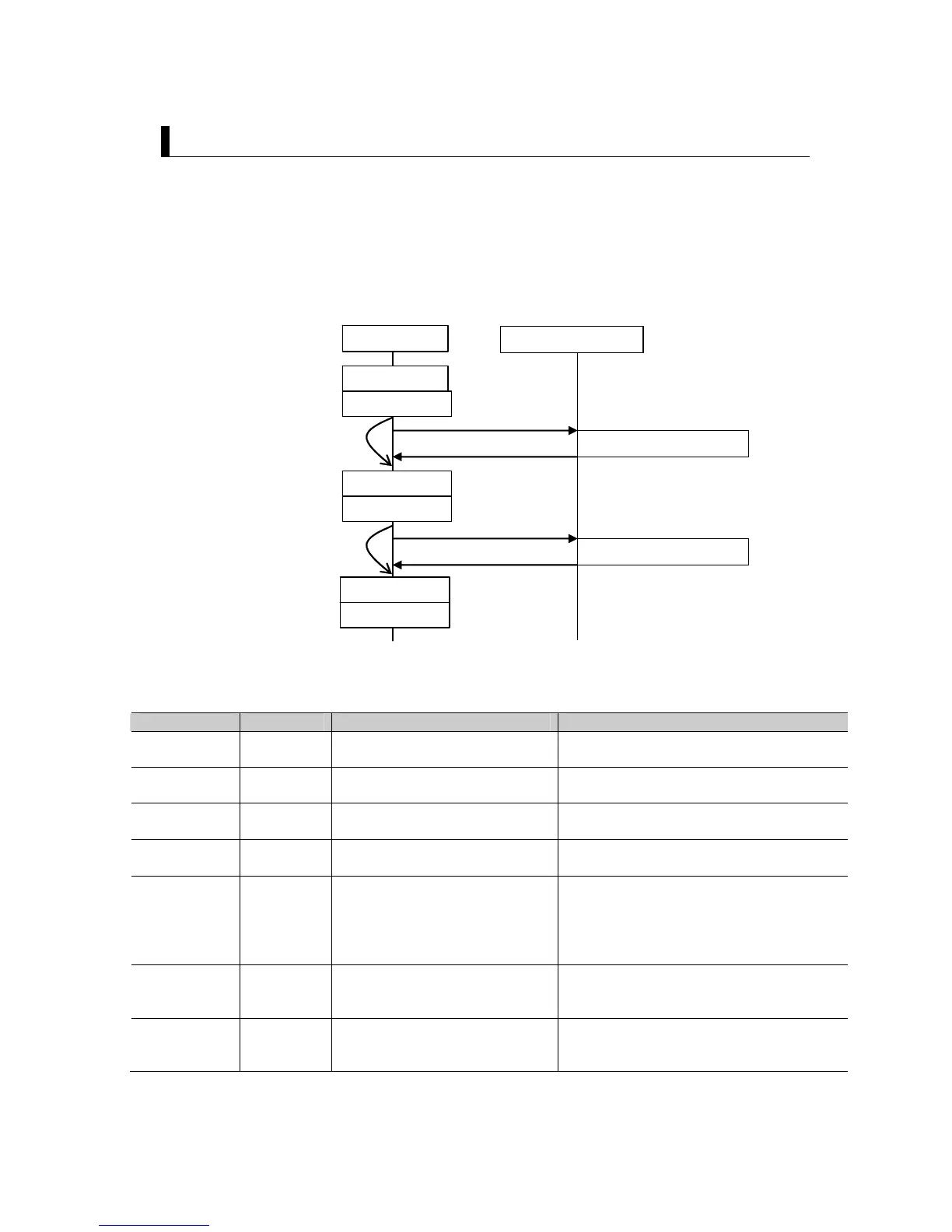

z Ethernet Communications Sequence

The G9SP-series Controller returns a response to the command sent from the

Standard PLC.

Standard PLC

G9SP-series Controller

Sent command

Reception response

Receive processing

after 300 ms

Send/Receive processing

Initialization

Send processing

Receive processing

Send processing

Sent command

Reception response

Send/Receive processing

Receive processing

Send processing

Receive processing

after 300 ms

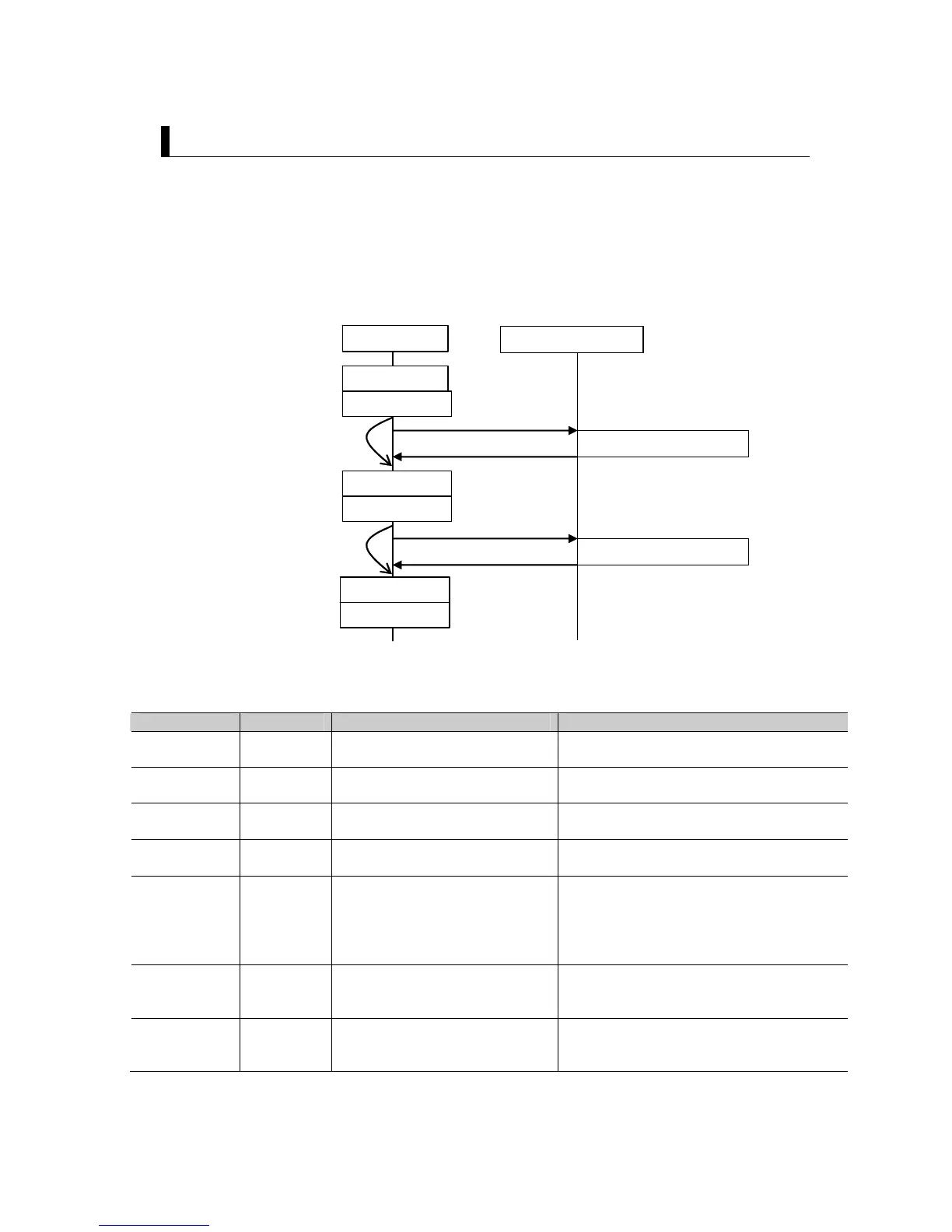

z Siemens PLC Memory Allocations

Start address End address Contents Description

DB201.0 DB201.23 Ethernet send command Data sent by the Standard PLC to the

G9SP-series Controller

DB201.50 DB201.261 Ethernet reception response Data received by the Standard PLC from

the G9SP-series Controller

DB200.4.0 DB200.6.0 FC6 instruction control data Control data for the FC6 instruction is

stored.

DB200.4.0 DB200.6.0 FC5 instruction control data Control data for the FC5 instruction is

stored.

IW100 IW101 G9SP communications reception data

(written to G9SP-series Controller)

Data written to G9SP-series Controller from

Standard PLC. Stored in the communica-

tions reception data of the G9SP-series

Controller. (Refer to Operation Manual

7-1-3 Transmission/Reception Data.)

QW100 QW101 G9SP communications transmission

data (read from the G9SP-series Con-

troller)

Communications data sent from the G9SP-

series Controller is read. (Refer to Operation

Manual 7-1-3 Transmission/Reception Data.)

QW102 QW104 G9SP Safety Input terminal data (read

from the G9SP-series Controller)

Safety Input terminal data of the G9SP-

series Controller is read. (Refer to Operation

Manual 7-1-3 Transmission/Reception Data.)

-

Loading...

Loading...