3-20

3-1 Servo Drive Specifications

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

3

Specifications

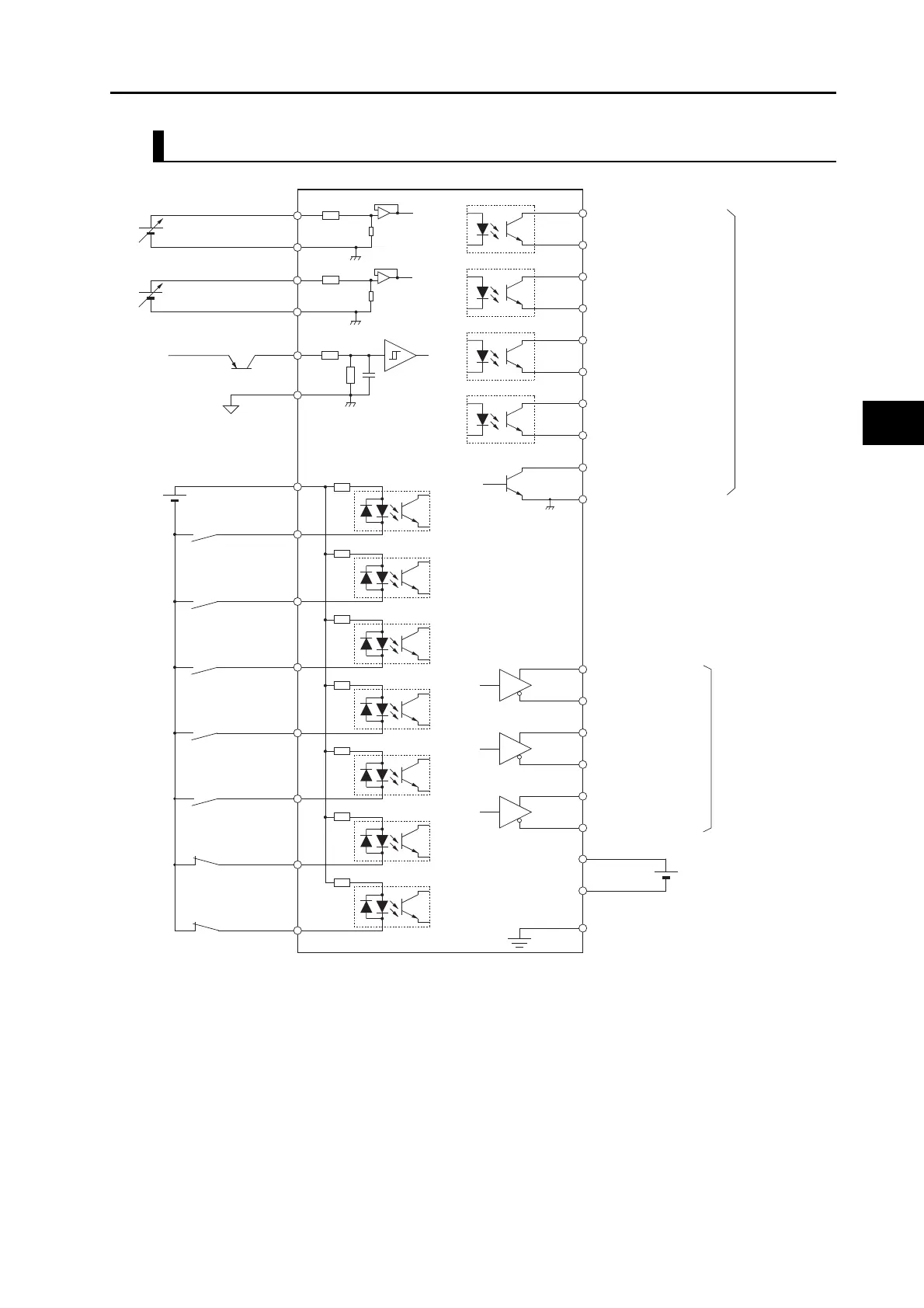

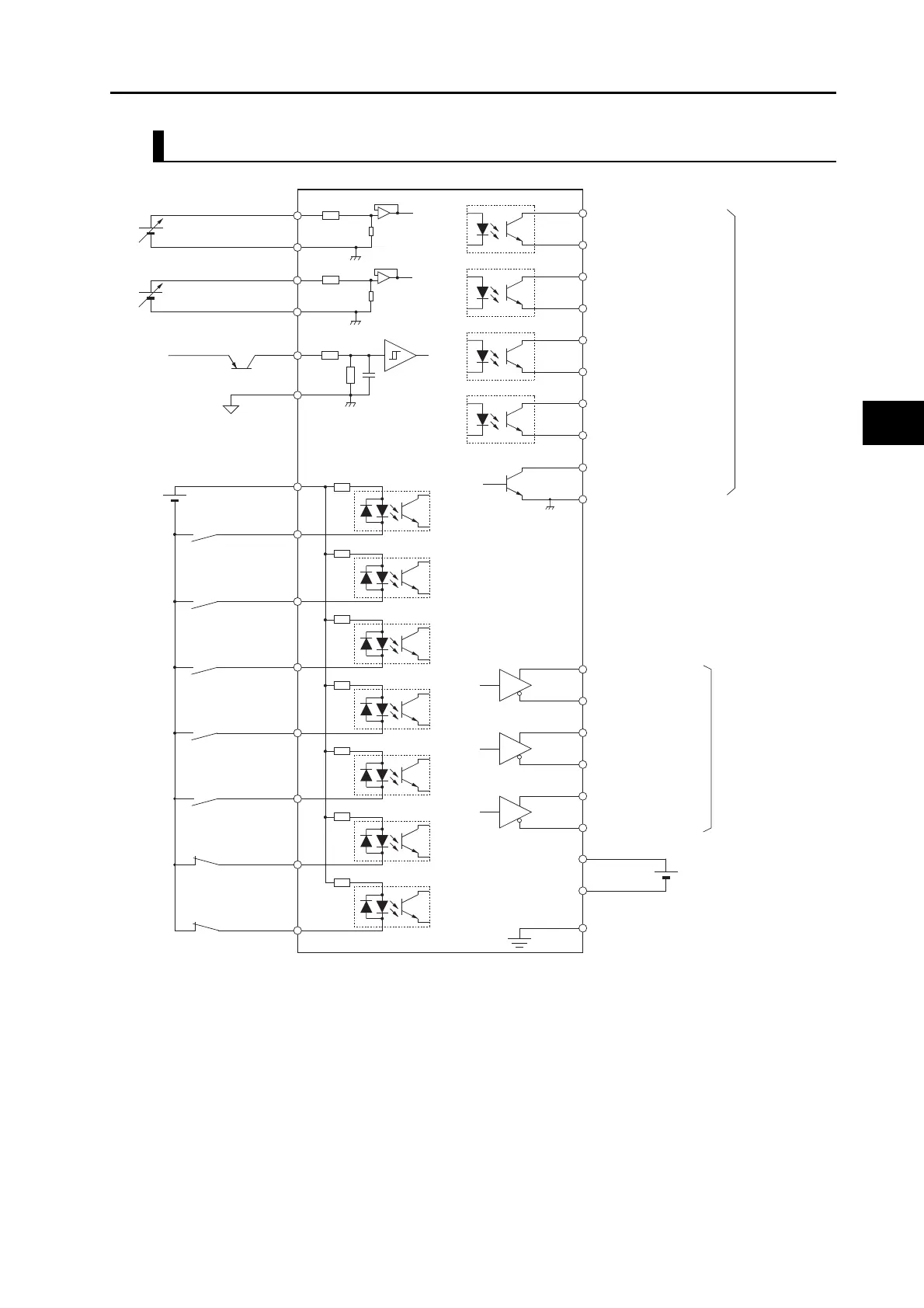

Control I/O Signal Connections and External Signal Processing for Torque Control

*1. A cable equipped with a battery is not required if a backup battery is connected.

Note 1. The inputs of pins 8, 9 and 26 to 33, and outputs of pins 10, 11, 34, 35, 38 and 39, can be changed via parameter

settings.

Note 2. Pins 13, 20, 42 and 43 represent signals which are applicable when an absolute encoder is used.

Note 3. If pins 21, 22, 49, 48, 23, and 24 are used for the encoder output, use pin 25 (ZGND) to wire the ground.

Note 4. It is not necessary to wire input pins that are not being used.

20

100 Ω

4.7 kΩ

1 μF

SEN

SENGND

13

Sensor ON

BAT

BATGND

Backup battery

*1

42

43

Operation

command

BKIR

Brake interlock

Alarm output

BKIRCOM

11

10

READY

READYCOM

ALMCOM

35

34

/ALM 37

36

TGONCOM

TGON

39

38

9

TVSEL

8

RESET

32

31

27

GSEL

26

VZERO

29 RUN

7

+24VIN

Control mode

switching

Alarm reset

Gain switching

Zero speed

designation

12 to 24 VDC

Maximum

service voltage

30 VDC

Maximum

output current:

50 mA DC

NOT

Reverse drive

prohibition

POT

Forward drive

prohibition

ZGND

Z

19

25

Frame ground

FG

Shell

4.7 kΩ

+A 21

−A 22

+B 49

−B 48

+Z 23

−Z 24

Line-driver output

corresponding with

the EIA RS-422A

communications

method

(load resistance

120 Ω min.)

4.7 kΩ

4.7 kΩ

4.7 kΩ

4.7 kΩ

4.7 kΩ

4.7 kΩ

TREF1/VLIM

AGND1

3.83 kΩ

20 kΩ

3.83 kΩ

10 kΩ

TREF2

AGND2

Torque command input

16

17

14

15

Encoder

phase-A output

Encoder

phase-Z output

Encoder

phase-B output

Phase-Z output

(open-collector

output)

Servo ready

completed output

Motor rotation

speed detection

output

Torque command input

or speed limit

Loading...

Loading...