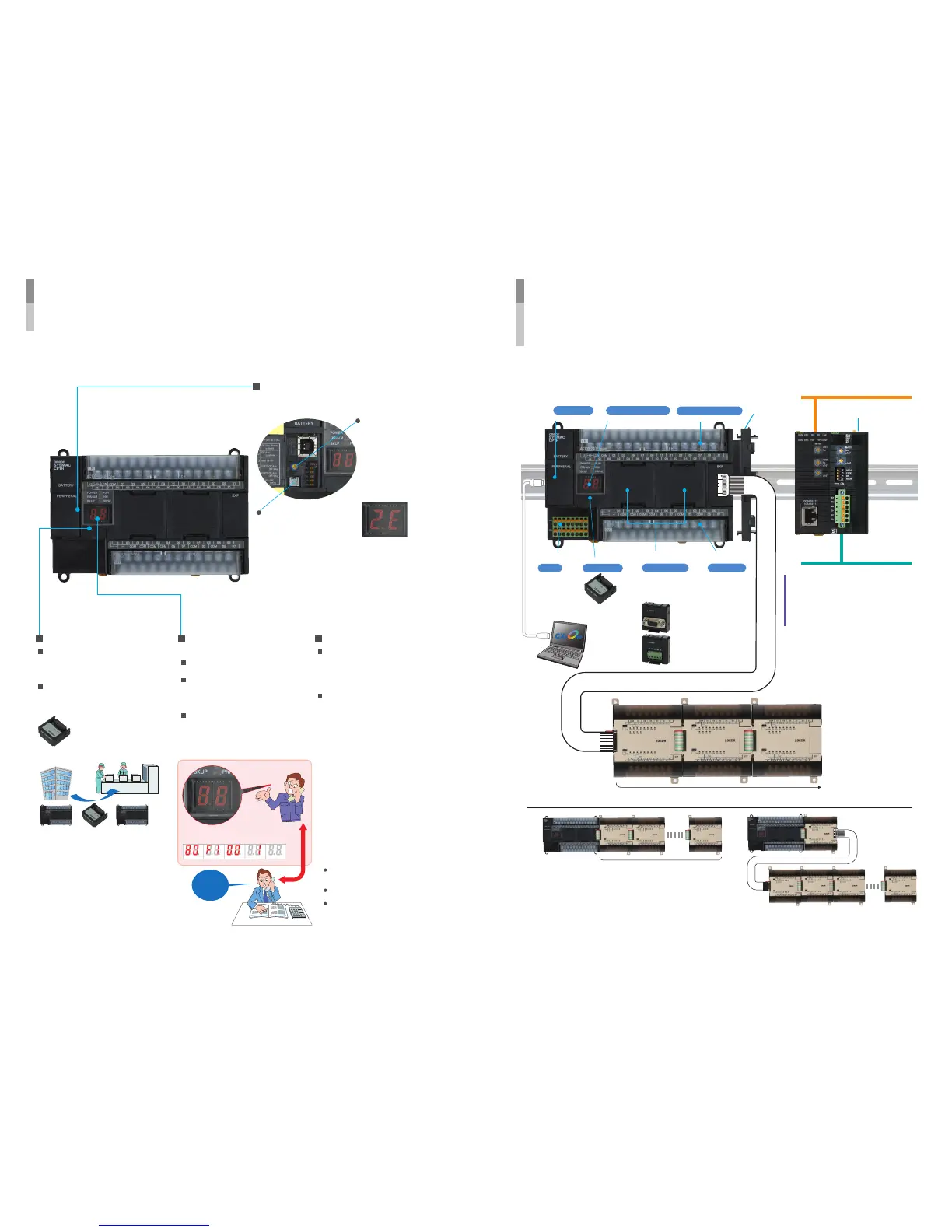

Analog Inputs Are Made Simple.

An analog adjustment and an external analog

setting input connector are provided.

Analog Adjustment

CP1W-ME05M

Memory Cassette

PLC program design

Memory Cassette

Production site

Production site

System

development

That’s a

memory

error.

Example display: A memory error occurs in the

UM (error code 80F1, error details 0001).

Handy Built-in Functions

Make Maintenance Easier.

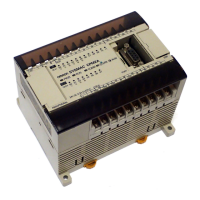

DeviceNet

CompoBus/S

Serial Communications

Ethernet

Controller Link

Over-the-counter

USB cable

Analog I/O

(CP1H-XA

CPU Units

Only)

Peripheral USB port 7-segment display Built-in Input Terminal Block

Built-in Output Terminal

Block

RS-232C or RS-422A/485

Option Boards

Built-in Analog

I/O Terminal Block

Memory Cassette

High-speed Counters for Four Axes

Serial Communications Four Pulse Outputs

Saving the Program

Analog I/O

Status and Operation Monitoring

Peripheral Devices

Only one I/O Connecting Cable can be used.

Expansion I/O Units can also be wired below by using

CP1W-CN811 I/O Connecting Cable.

7 Units max.

7 Units max.

CP1W-CN811

I/O Connecting

Cable: 80 cm

Memory Cassette

The analog adjustment

has a resolution of 256.

Values are entered in

A642 and can be used

in the ladder program.

When the value is

changed, it is displayed

(0 to FF) for three

seconds on the 7-

segment display.

External Analog Setting

Input Connector

This connector has a resolution of

256 and is used for an analog

input set to 0 to 10 V. Each CP1H

CPU Unit has one of these

connectors built in. (The built-in

analog I/O for CP1H-XA CPU Units

is separate.)

A device, such as a

potentiometer, can be connected

to enable direct manual operation

and control from a control panel.

The maximum cable length is 3

meters. A connecting cable (1 m)

is included with the CPU Unit.

Data, such as programs and initial

memory values, can be stored on a

Memory Cassette (optional) and

copied to other systems.

The Memory Cassette can also be

used when installing new versions

of application programs.

Status Displayed on

7-segment Display

The 7-segment display provides

two display digits.

In addition to displaying error codes

for errors detected by the PLC,

codes can be displayed on the

display from the ladder program.

The 7-segment display is useful for

maintenance as well, allowing

problems that arise during system

operation to be grasped without

using any Support Software.

Battery-free Operation

The values in the DM Area

(32 Kwords) are saved in the

CPU Unit’s built-in flash

memory as initial values,

and can be read at startup.

Battery-free operation is

also possible when saving

production data and

machine parameters in the

DM Area, turning OFF the

power, and using then same

data again for the next

production run.

A battery is required for the clock

function and to retain the status of

HR Area bits and counter values.

A battery is provided as a standard

feature with the CPU Unit.

The user program (ladder

program) is stored in built-in flash

memory, so no battery is required

to back it up.

Communications Expansion to

Higher and Lower Network

Layers, System Expansion, and

Information Management Are

Made Easy.

Use a CP1W-CN811 I/O

Connecting Cable when using

CPM1A Expansion I/O Units

with a CJ Unit Adapter.

A maximum of seven CPM1A Expansion I/O Units can be

connected. For details on Unit restrictions, refer to page

16.

Up to 320 I/O points can

be obtained by

connecting seven

Expansion I/O Units.

Note:

Loading...

Loading...