OPERATION

CRANKCASE

OIL

Use an oil

with

the API designation CD/SE, or CD/SO

(formerly

OS)

that has passed the Series 3

Test

and at

least

Sequences

IIA

and·

ilIA

of the Automotive

Manu-

facturer's

MS

Sequence Te.sts.

(OM

oil which has passed

the Automotive Manufacturer's

MS

Sequence

Tests

and

the

MIL-L-2104B

Tests

may

also be used when ambient tempera-

tures are lower than

30°F.)

To reduce

oil

consumption

to

a

normal

level

in

the shortest time

on

a

new

or rebuilt

"]"

series

diesel engine,

use

CC

(formerly

OM)

oil

(pass-

ing

the

MS

Sequence

Tests)

for

the

first fill only

(50

to 100

hours), then change to the recommended oil.

TEMPERATURE

GRADE

Above

32°F

SAE

30

OaF

to

32°F

SAE

lOW-3~,

SW-20,

or

lOW,SW-30

SAE

SW-20

or

SW-30

Do

not

mix

brands

or

grades. Refer to Maintenance Section

for

recommended oil changes.

;0

RECOMMENDED

FUEL

Depends

on

operating condi tions. Use

NO.2

diesel fuel for

best

economy. Use

NO.

I diesel fuel (a)

when

ambient

tem-

perature

is

below

32

OF.,

or (b) at all temperatures during

long periods of light engine load,

(c)

if

preferred

by

user.

Use low sulfur content fuel having a pour point (ability to

filter) of at

least

100F. below the lowest expected tempera-

ture. Keep fuel clean

and

protected

from

adverse weather.

Leave some

room

for

expansion

when

filling the tank.

INITIAL

START

Check the engine

to

make sure

it

has been filled with oil

and that fuel system

is

air- free.

Bleed air

from

fuel system

as

follows: Disconnect the fuel

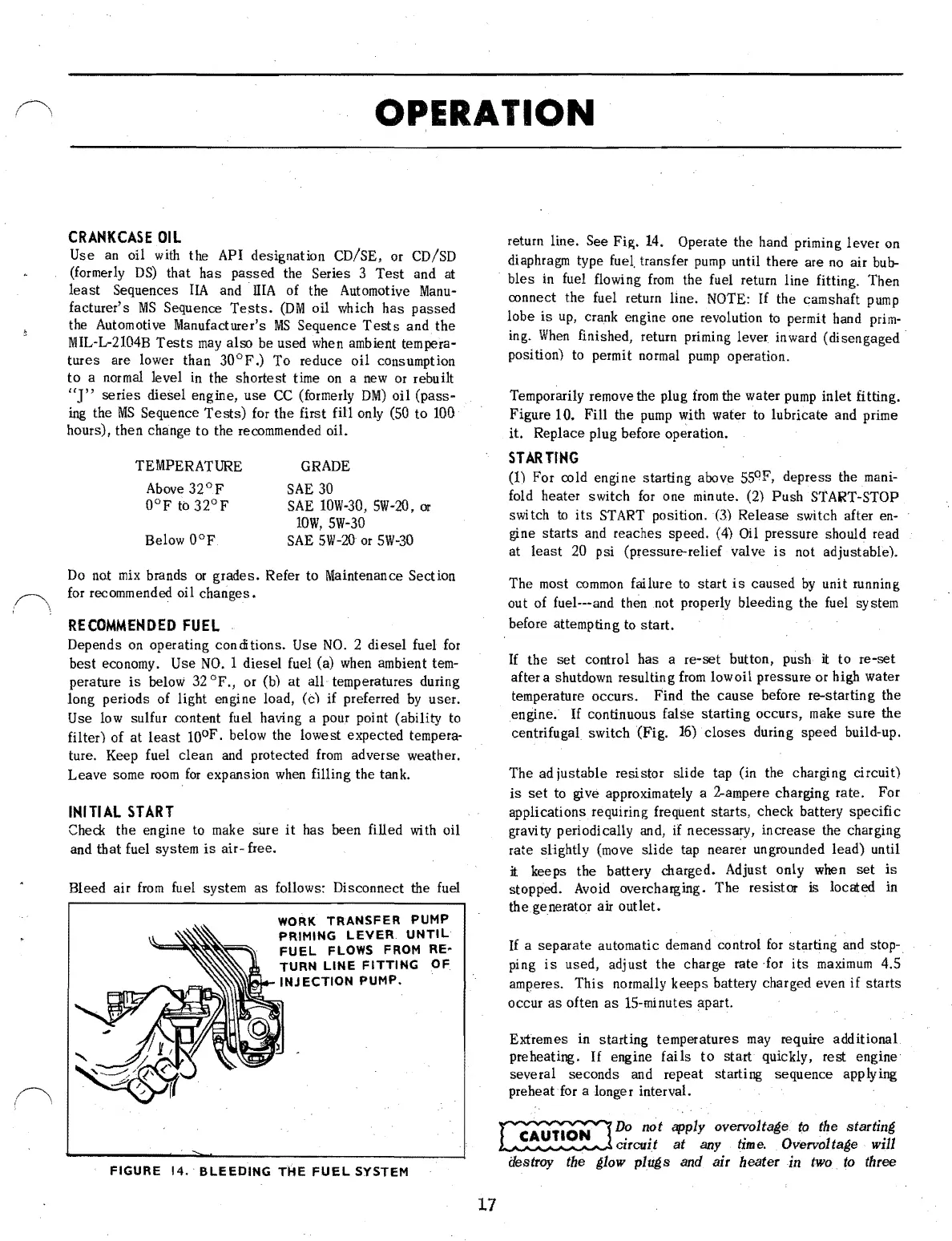

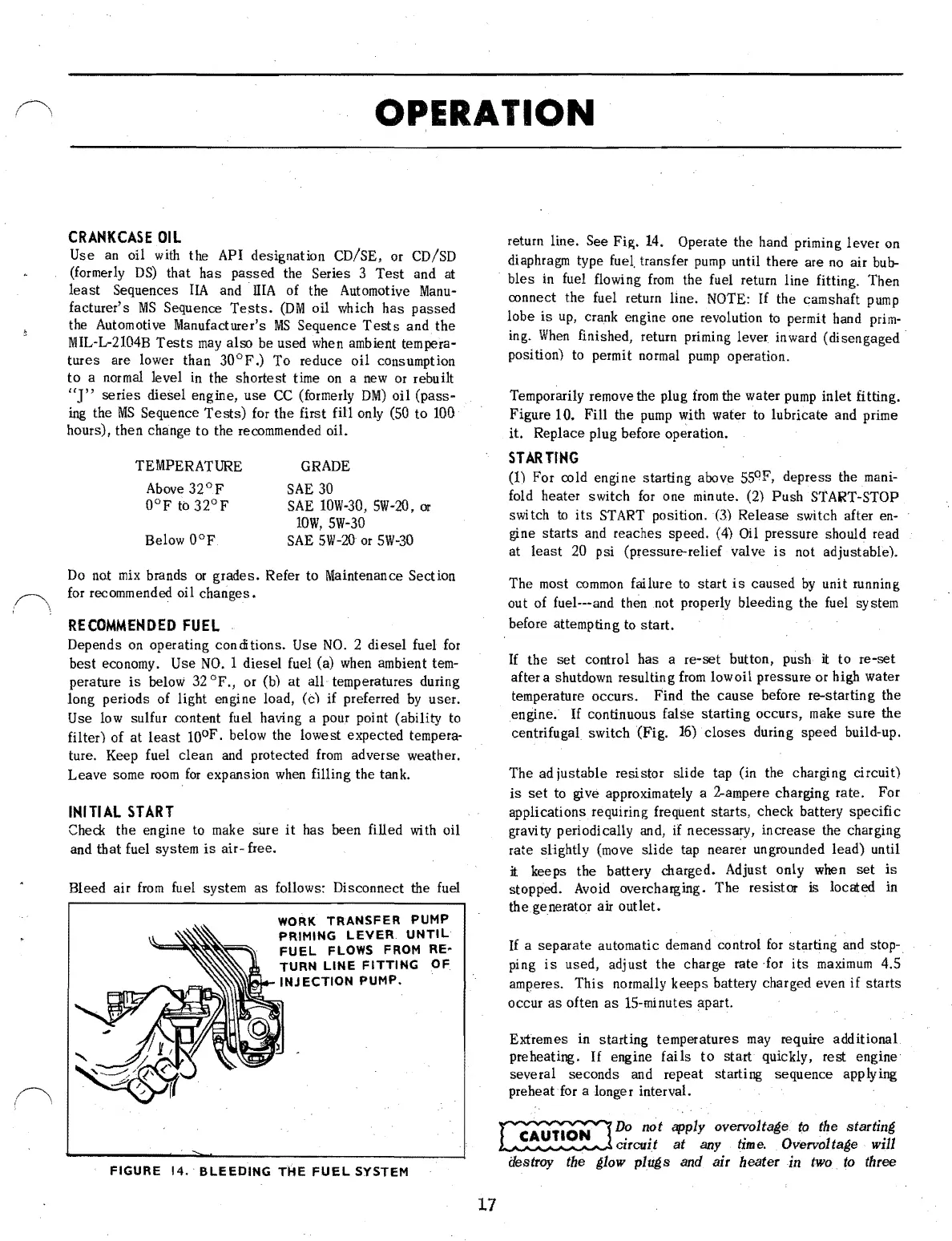

WORK

TRANSFER

PUMP

PRIMING

LEVER

UNTIL

FUEL

FLOWS FROM

RE·

TURN

LINE

FITTING

OF

INJECTION

PUMP.

FIGURE

14.·

BLEEDING

THE

FUEL

SYSTEM

return line. See Fig. 14. Operate the hand priming lever on

diaphragm type fuel. transfer

pump

until there are

no

air

bub-

bles

in

fuel flowing

from

the fuel return line fitting. Then

connect the fuel return line.

NOTE:

If

the camshaft

pump

lobe

is

up,

crank engine one revolution

to

permit hand

prim-

ing.

When

finished, return priming lever inward (disengaged·

position)

to

permit normal

pump

operation.

Temporarily remove the plug

from

the water

pump

inlet

fitting.

Figure 10. Fill the

pump

with water

to

lubricate and prime

it. Replace plug before

op~ration.

STARTING

(1) For cold engi ne starting above

55

0

F, depress the

mani-

fold heater switch

for

one minute. (2) Push START-STOP

switch

to

its

START

position.

(3)

Release switch after en-

gine starts and reaches speed. (4) Oil pressure should read

at

least

20 psi (pressure-relief valve

is

not adjustable).

The most

common

failure

to

start

is

caused

by

unit

r.unning

out of fuel---and then not properly bleeding the fuel system

before attempting

to

start.

If

the

set

control has a re-set button, push it to re-set

after a shutdown resulting

from

lowoil pressure or high water

temperature occurs. Find the

cause

before re-starting the

engine.

If

continuous false starting occurs, make sure the

centrifugal switch (Fig. 16)·

closes

during speed build-up.

The ad justable resistor slide tap (in the charging circuit)

is

set

to

give approximately a 2-ampere charging rate. For

applications requiring frequent starts, check battery specific

gravi

ty

periodically and, if necessary, increase the charging

rate slightly (move slide tap nearer ungrounded lead) until

it keeps the battery charged. Adjust only when

set

is

stopped.

Avoid

overcharging. The resistor is located in

the generator air outlet.

If

a separate automatic demand control

for

starting and stoP-.

ping

is

used, adjust the charge rate ·for

its

maximum

4.5

amperes. This normally keeps battery charged even

if

starts

occur

as

often

as

IS-minutes apart.

Extremes in starting temperatures

may

require additional

preheating.

If

engine

fails

to

start quickly, rest engine

several seconds and repeat starting sequence applying

preheat

for

a longer interval.

~

D?

n?t apply

oVen>:

..

olta;,e

to

the

starti~;,

~

cIrcuIt

at

any

time.

Overvolta;,e

WIll

destroy the ;,low plu;,s

and

air heater in two.

to

three

17

Loading...

Loading...