light loads. Apply full load occasionally before shut-down

to

prevent excessive carbon accumulations.

Try to connect

the

load

in

steps

instead of full load

at

one time. Most installations use a line switch

that

must

be

closed

to

connect a portion of the load.

EXERCISE

STANDBY

SETS

Infrequent set

use

results

in

hard setting. Operate standby

set a

least

30

minutes

each

week.

Run

longer

if

battery

needs charging.

BREAK·IN

PROCEDURE

The unit should

be

run

in

the following sequence:

1.

One

half

hour at 1/2 load.

2. One half hour at

3/4

load.

3.

Full

load.

Continuous running under one half load during the first

few

hundred hours

usually.

results in poor piston ring

. seating, causing higher than normal oil consumption and

blowby.

MOTE:

Drain

the initial oil after SOhours

of

operation

while the engine

is

still hot.

SAFElY

DEVICES

In

case

of

dangerously high coolant (water) temperature or

low oil pressure,

the

cut-off switch stops the unit. After an

emergency stop, investigate and correct the

cause.

Press

re-set button before restarting.

EMERGENCY

OPERATION

IF

BATTERY

FAILS

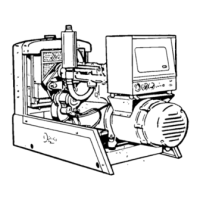

MD

JF generating

sets

require a battery

for

running.

If

the

set battery

fails

completely and set must be operated during

an emergency, a battery can be shared

with

ether equipment

provided

the

set

charging circuit is disconnected

as

follows:

Remove the ammeter wire connected

to

terminal

No.8

in

the

cootro! box and tape the bare end. The

set

will not charge

the battery with

this

lead

wire

disconnected.

HEAT

EXCHANGER

(OPTIONAL)

FILLING

Improper filling of the heat exchanger can

cause

overheating·

of the e!lgine. Therefore, to prevent

this

possibility, follow

these

instructions whenever adding Icooling

to

the heat

exchanger:

1.

Remove fill cap.

2.

Open

fill vent valve (turn counterclockwise).

3. Remove vent plug, (Spec A through C).

4.

Fill

with

coolant.

5.

Close

fil.}

vent valve (turn clockwise).

6. Replace vent plug. (Spec A through C).

7. Replace fill cap.

8.

Operate unit 10 minutes at full load, watch

for

leaks.

9.

Shutdown unit.

After

running

unit

10

minates, the

closed cooling system

is

pressurized

and hot.

Open

the 14

lb.

preSSfJre

cap

slowly

to

vent

pressure.

10. Slowly open pressure cap and check water level.

11.

Fill

system to

top

with coolant.

OUT-Of·SERVICE

PROTECTION

When

taking unit out of service

for

30-days

or

longer, proper

storage methods must be used

to

prevent damage

from

cor-

rosion, contamination,

and

temperature extremes.

Fuel System

1.

Clean air cleaner

(if

used) -

do

not service air cleaner

with

oiL Check and clean air intake.

2.

Cover

or

seal exposed air intake openings.

3.

Clean throttle linkage (and governor linkage) thoroughly.

Lubricate metal ball

joints

with light machine oil (do

not lubricate plastic ball joints) .

Oil

System

1.

Drain engine lubricating oil while engine

is

warm.

Serv-

ice the engine with proper oil.

TAG

the engine

to

IDENTIFY the lubricating oil installed. Secure

the

oil

filter cap.

2. Remove fuel injectors. Pour 2 ounces of rust inhibitor

oil

(SAESO

substitute) into each cylinder. Crank e!lgine

over

by

hand several revolutions to lubricate cylinder

walls, pistons, and rings. Install injectors.

3.

Remove and service oil filter.

Cooling System

1.

Drain entire cooling system including water cooled ex-

haust manifold and exhaust line. Drain heat exchanger

or

keel cooler components, engine cylinder block, and

water pumps.

Senerating units equipped with heat exchanger or keel

cooling

may

be filled with a

good

quality anti-freeze if

freezing temperatures are expected. Drain only those

components not protected

from

freezing (exhaust lines,

water intake and outlet lines, etc.).

19

Loading...

Loading...