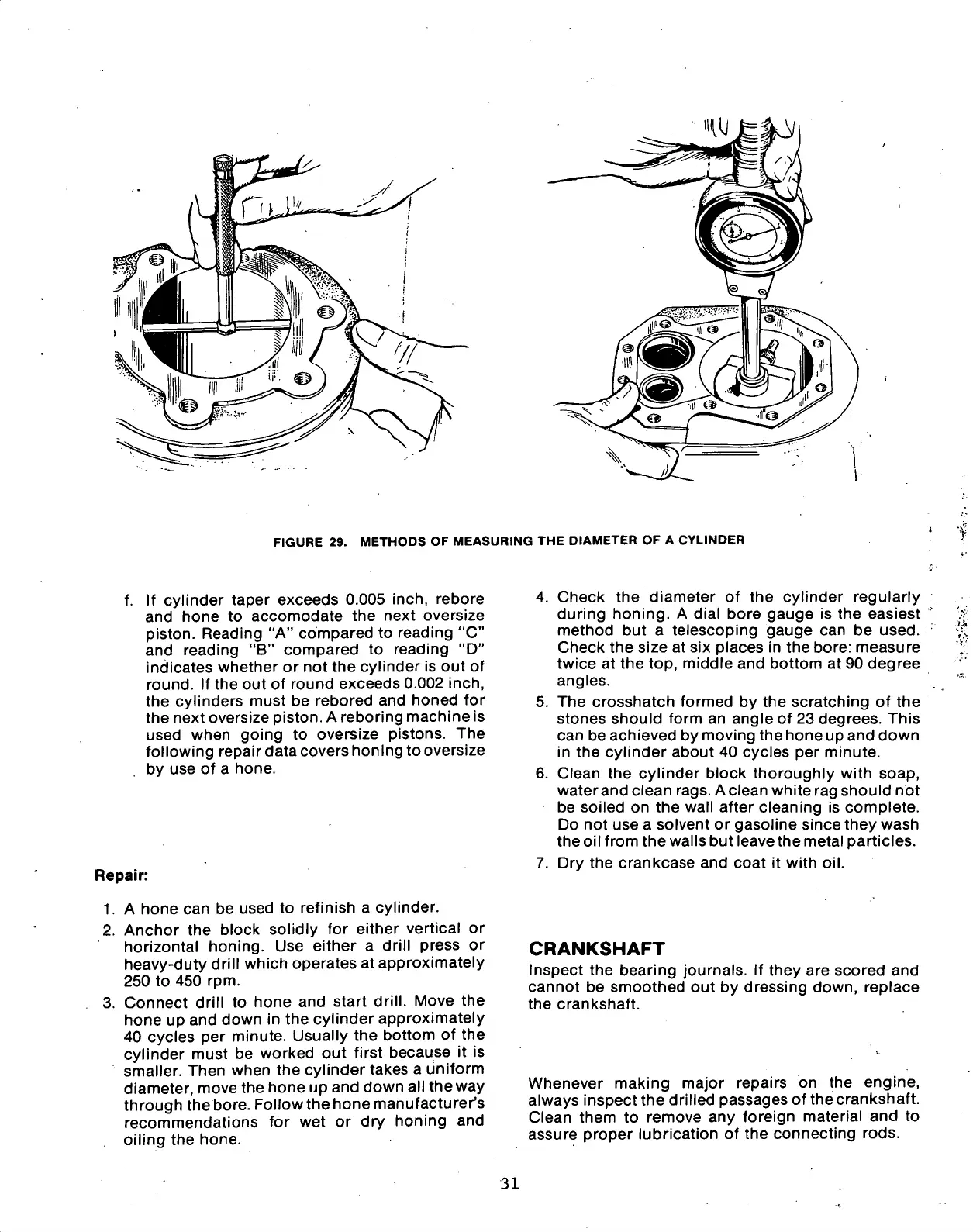

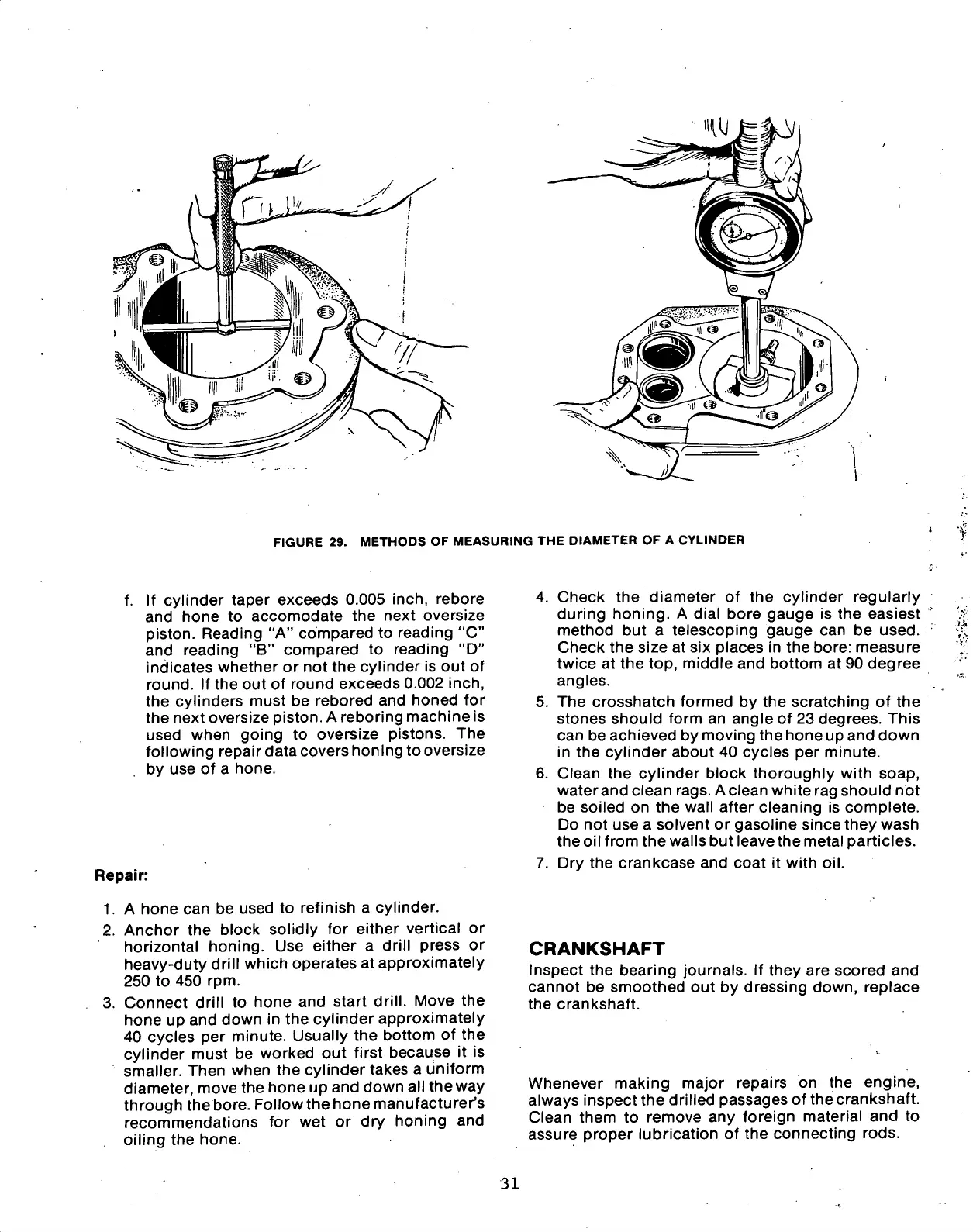

FIGURE 29. METHODS OF MEASURING THE DIAMETER OF A CYLINDER

If cylinder taper exceeds 0.005

inch,

rebore

and hone to accomodate the next oversize

piston.

Reading "A" compared to reading "C"

and reading "B" compared to reading "D"

indicates whether or not the cylinder is out of

round.

If the out of round exceeds 0.002

inch,

the cylinders must be rebored and honed for

the next oversize piston. A reboring machine is

used when going to oversize pistons. The

following repair data covers honing to oversize

by use of a hone.

Repair:

1.

A hone can be used to refinish a cylinder.

2.

Anchor the block solidly for either vertical or

horizontal honing. Use either a drill press or

heavy-duty drill which operates at approximately

250 to 450 rpm.

3. Connect drill to hone and start

drill.

Move the

hone up and down in the cylinder approximately

40 cycles per minute. Usually the bottom of the

cylinder must be worked out first because it is

smaller. Then when the cylinder takes a uniform

diameter, move the hone up and down all theway

through the bore. Follow the hone manufacturer's

recommendations for wet or dry honing and

oiling the hone.

4.

Check the diameter of the cylinder regularly

during honing. A dial bore gauge is the easiest

method but a telescoping gauge can be used.

Check the size at six places in the bore: measure

twice at the top, middle and bottom at 90 degree

angles.

5. The Crosshatch formed by the scratching of the

stones should form an angle of 23 degrees. This

can be achieved by moving the hone up and down

in the cylinder about 40 cycles per minute.

6. Clean the cylinder block thoroughly with soap,

waterand clean rags. A clean white rag should not

be soiled on the wall after cleaning is complete.

Do not use a solvent or gasoline since they wash

the oil from the walls but leave the metal particles.

7. Dry the crankcase and coat it with oil.

CRANKSHAFT

Inspect the bearing journals. If they are scored and

cannot be smoothed out by dressing down, replace

the crankshaft.

Whenever making major repairs on the engine,

always inspect the drilled passages of the crankshaft.

Clean them to remove any foreign material and to

assure proper lubrication of the connecting rods.

31

Loading...

Loading...