AVOID THIS FINISH

PRODUCE CROSS HATCH SCRATCHES

FOP.

FAST RING SEATING

FIGURE 30. CROSSHATCHING

BEARINGS

(Figures

31-33)

Removing camshaft or crankshaft bearings requires

complete disassembly of the engine. Use a press or a

suitable drive plug to remove the bearings. Support

the casting to avoid distortion and avoid damaging

the bearing bore during removal and installation. Use

oil on the bearings to reduce friction when installing

and again lubricate with oil after installing.

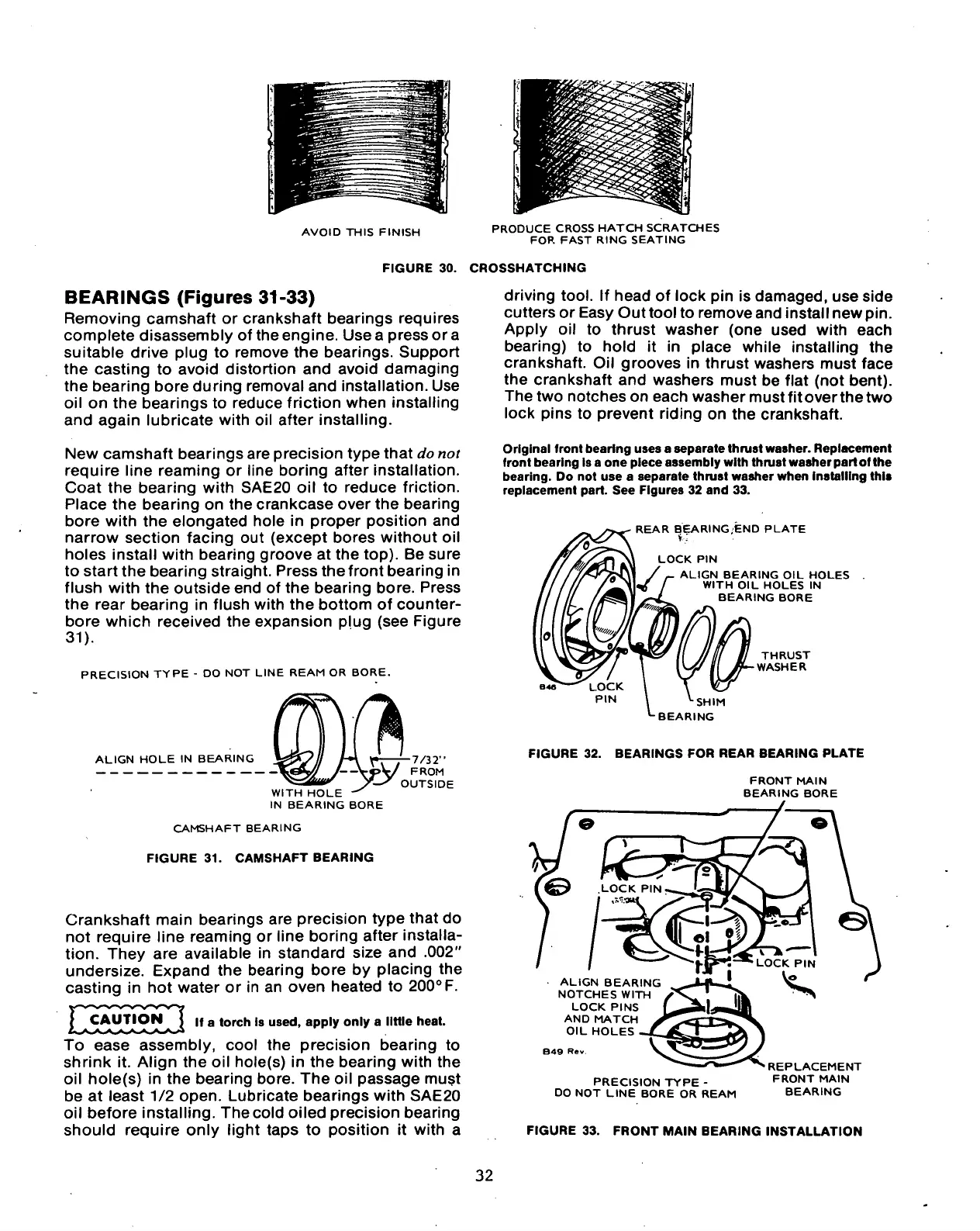

New camshaft bearings are precision type that do not

require line reaming or line boring after installation.

Coat the bearing with SAE20 oil to reduce friction.

Place the bearing on the crankcase over the bearing

bore with the elongated hole in proper position and

narrow section facing out (except bores without oil

holes install with bearing groove at the top). Be sure

to start the bearing straight. Press the front bearing in

flush with the outside end of the bearing bore. Press

the rear bearing in flush with the bottom of counter-

bore which received the expansion plug (see Figure

31).

PRECISION TYPE - DO NOT LINE REAM OR BORE.

ALIGN HOLE IN BEARING

\ \ I "

7/32

"

«>V/ FROM

, OUTSIDE

WITH HOLE

IN BEARING BORE

CAMSHAFT BEARING

FIGURE 31. CAMSHAFT BEARING

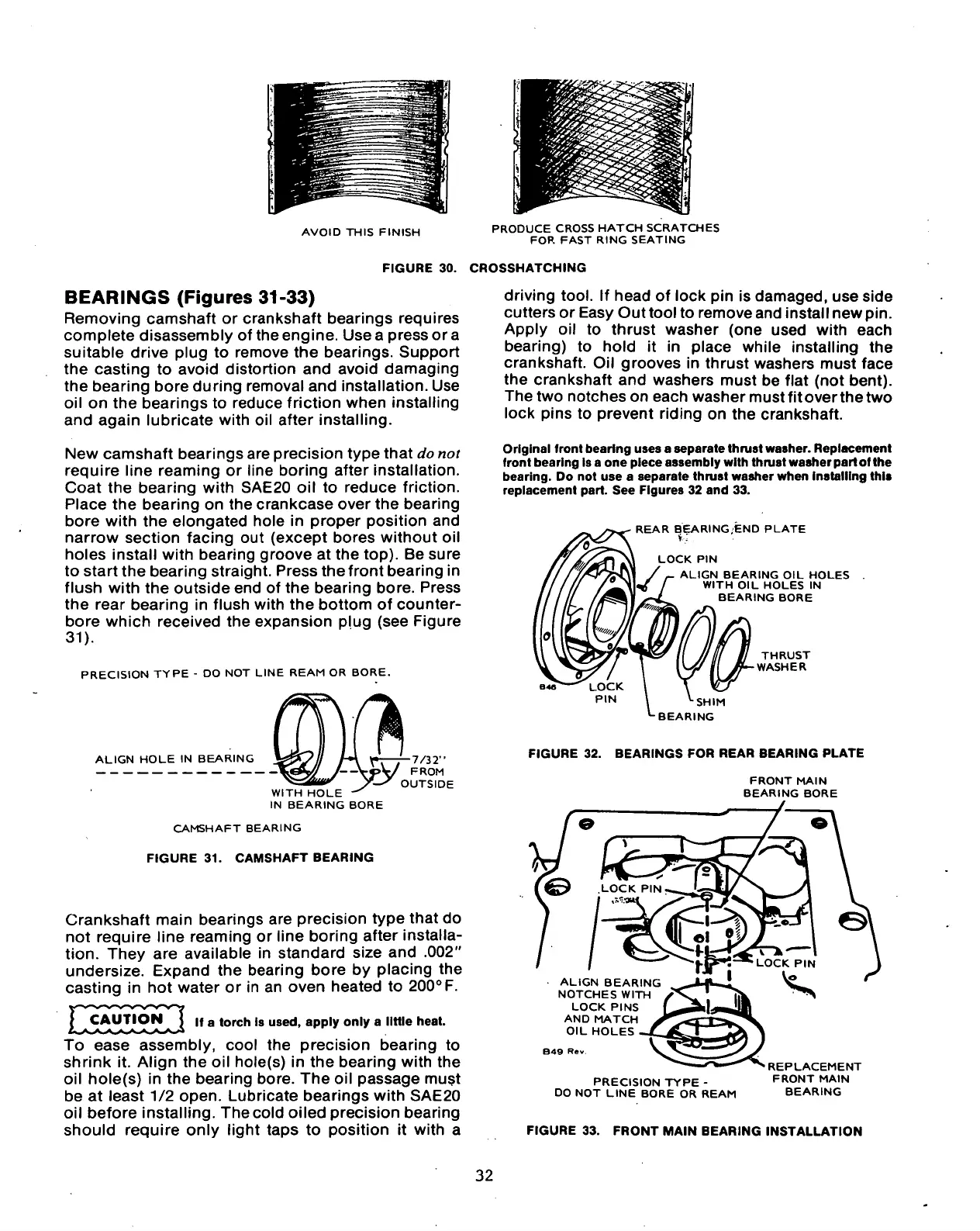

Crankshaft main bearings are precision type that do

not require line reaming or line boring after installa-

tion.

They are available in standard size and .002"

undersize. Expand the bearing bore by placing the

casting in hot water or in an oven heated to 200°F.

JCAUTION

If a torch is used, apply only a little heat.

To ease assembly, cool the precision bearing to

shrink it. Align the oil hole(s) in the bearing with the

oil hole(s) in the bearing bore. The oil passage must

be at least 1/2 open. Lubricate bearings with SAE20

oil before installing. The cold oiled precision bearing

should require only light taps to position it with a

driving

tool.

If head of lock pin is damaged, use side

cutters or Easy Out tool to remove and install new pin.

Apply oil to thrust washer (one used with each

bearing) to hold it in place while installing the

crankshaft. Oil grooves in thrust washers must face

the crankshaft and washers must be flat (not bent).

The two notches on each washer must fit over the two

lock pins to prevent riding on the crankshaft.

Original front bearing uses a separate thrust washer. Replacement

front bearing Is a one piece assembly with thrust washer part of the

bearing.

Do not use a separate thrust washer when Installing this

replacement part. See Figures 32 and 33.

REAR BEARING/END PLATE

LOCK PIN

ALIGN BEARING OIL HOLES

WITH OIL HOLES IN

BEARING BORE

THRUST

WASHER

SHIM

BEARING

FIGURE 32. BEARINGS FOR REAR BEARING PLATE

FRONT MAIN

BEARING BORE

ALIGN BEARING

NOTCHES WITH

LOCK PINS

AND MATCH

OIL HOLES

B49 Rev

PRECISION TYPE -

DO NOT LINE BORE OR REAM

REPLACEMENT

FRONT MAIN

BEARING

FIGURE 33. FRONT MAIN BEARING INSTALLATION

32

Loading...

Loading...