FILTERS

A planned program of regular filter cleaning or

replacement will pay dividends in improved engine

life operation and reliability.

Air Filter Service air cleaner and replace element in

accordance with instructions in the engine manufac-

turer's manual. Perform this operation at times

specified in the operator maintenance schedule.

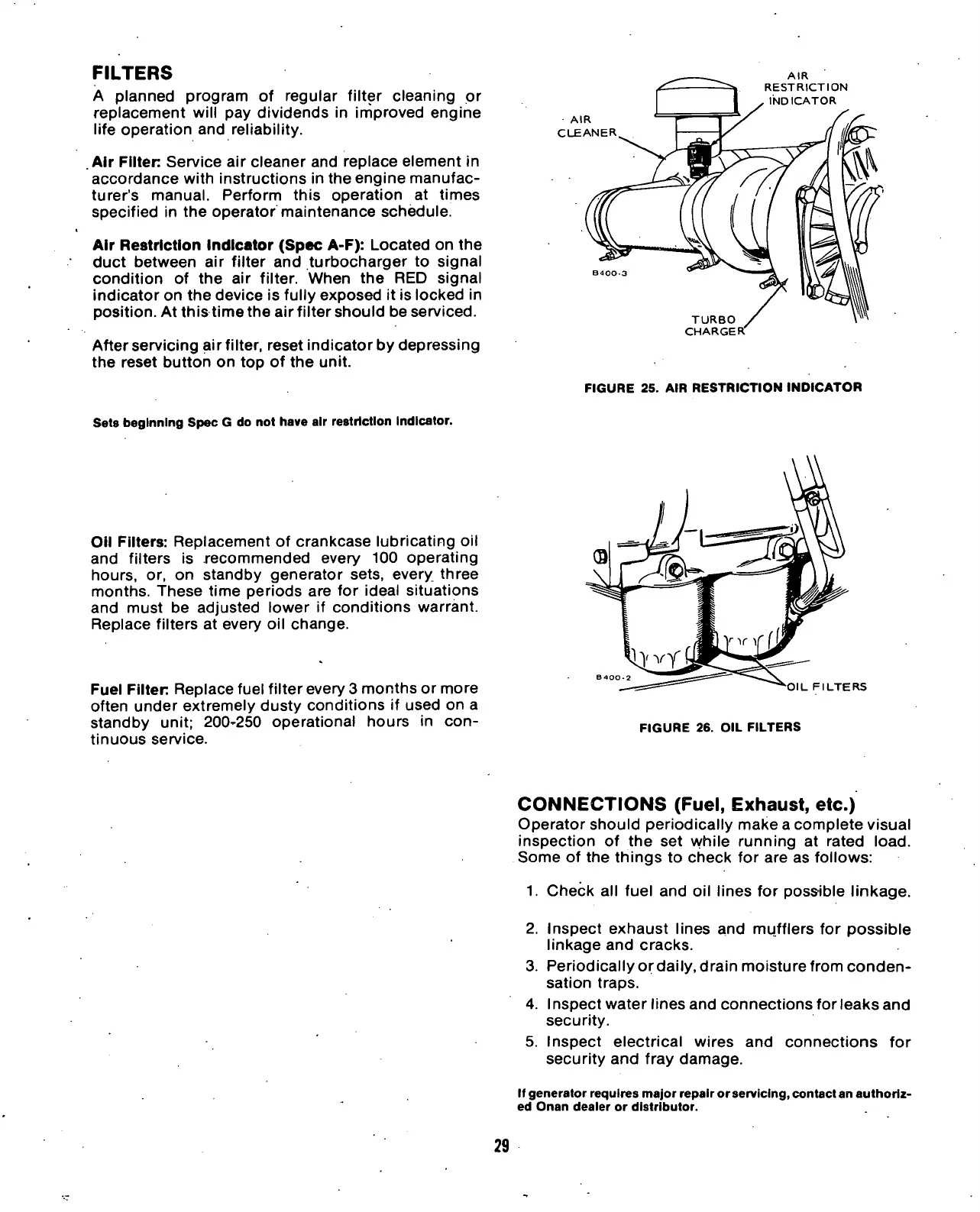

Air Restriction Indicator (Spec A-F): Located on the

duct between air filter and turbocharger to signal

condition of the air filter. When the RED signal

indicator on the device is fully exposed it is locked in

position.

At this time the air filter should be serviced.

After servicing air filter, reset indicator by depressing

the reset button on top of the unit.

Sets beginning Spec G do not have air restriction Indicator.

AIR

RESTRICTION

INDICATOR

AIR

CLEANER

TURBO

CHARGER'

FIGURE 25. AIR RESTRICTION INDICATOR

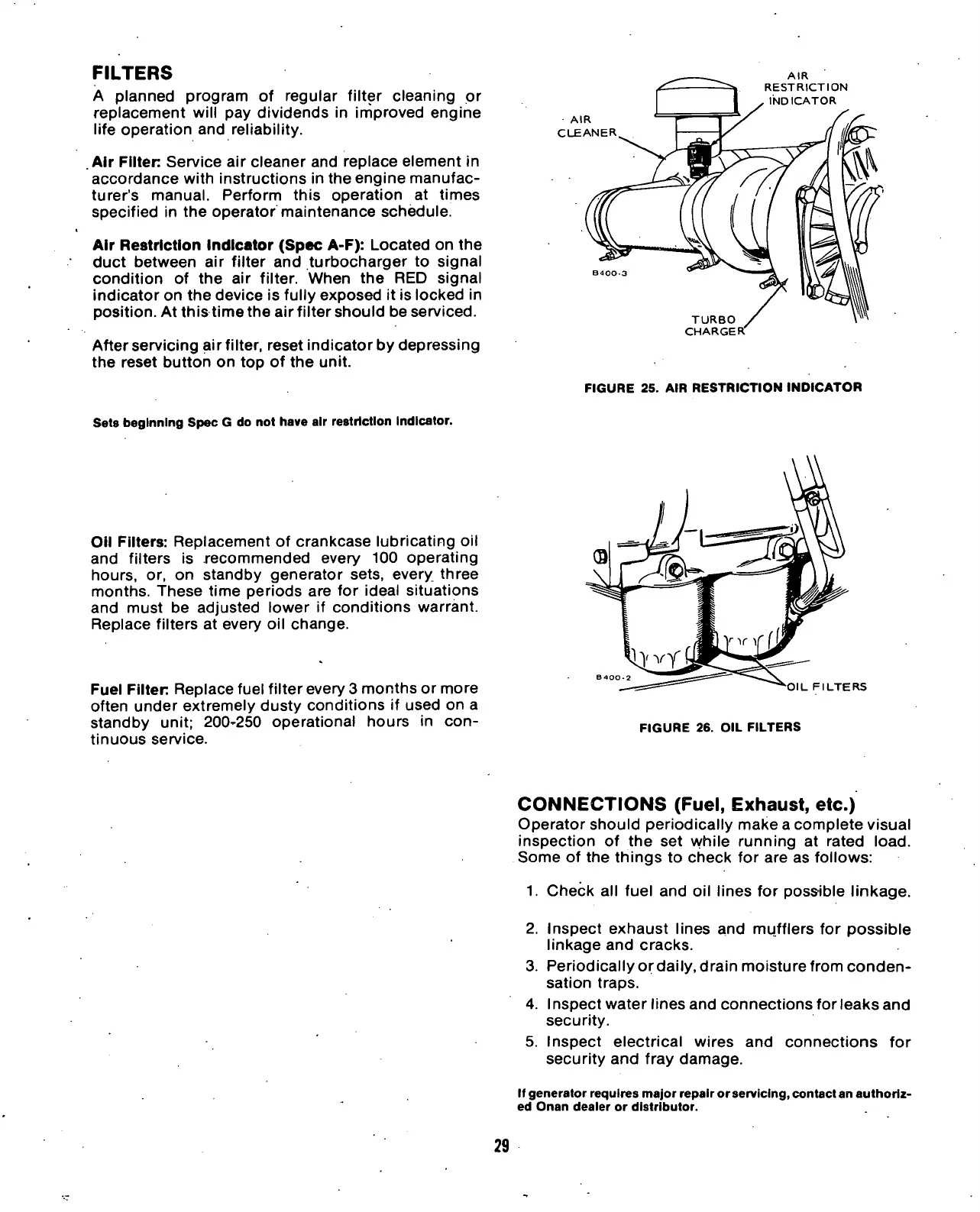

Oil Filters: Replacement of crankcase lubricating oil

and filters is recommended every 100 operating

hours,

or, on standby generator sets, every three

months. These time periods are for ideal situations

and must be adjusted lower if conditions warrant.

Replace filters at every oil change.

Fuel Filter Replace fuel filter every 3 months or more

often under extremely dusty conditions if used on a

standby unit; 200-250 operational hours in

con-

tinuous service.

LTE RS

FIGURE 26. OIL FILTERS

CONNECTIONS

(Fuel,

Exhaust,

etc.)

Operator should periodically make a complete visual

inspection of the set while running at rated

load.

Some of the things to check for are as follows:

1.

Check all fuel and oil lines for possible linkage.

2.

Inspect exhaust lines and mufflers for possible

linkage and cracks.

3. Periodicallyordaily.drain moisturefrom conden-

sation traps.

4.

Inspect water lines and connections for leaks and

security.

5. Inspect electrical wires and connections for

security and fray damage.

If generator requires major repair or

servicing,

contact an authoriz-

ed Onan dealer or distributor.

29

Loading...

Loading...